Reflective Double Tempered Laminated Glass 6+0.38+6mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters m²

- Supply Capability:

- 1500 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Function: Decorative Glass

Shape: Flat

Structure: Solid

Technique: Clear Glass,Laminated Glass,Tempered Glass

Type: Float Glass

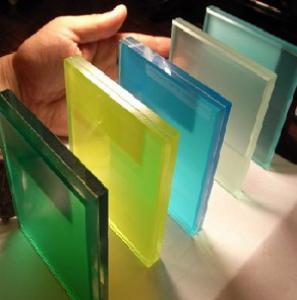

colour: clear,royal blue,ford blue,ocean blue,F-green

edge: grounding edge

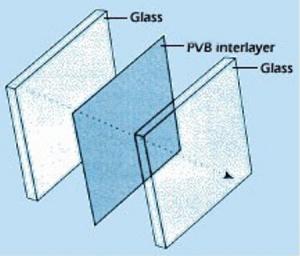

Interlayer: PVB

PVB thickness: 0.38mm0.76mm1.14mm1.52mm

Usage: building,windows,doors

PVB color: clear ,yellow,red ,green,blue and so on

Max size: 4200*2400mm

Min size: 300*300mm

certificate: ISO CCC

Raw material: float glass,tempered glass

Packaging & Delivery of Double Tempered Laminated Glass

Packaging Details: storng wooden crates with interlayer paper

Delivery Detail: within 15 days after receive deposit

Specifications of Double Tempered Laminated Glass

1.Extremely high safety

2.Energy-saving building materials

3.Sound control

4.Ultra-violet resistance

5.Decorative glass

Raw material

Float glass,Glaverbel glass,On-line coated glass,On line LOW-E,Off line LOW-E, On-line SUN-E and so on.

Color:clear,royal blue,ford blue,ocean blue,F-green,Green,dark grey,light grey,red bronze,golden bronze,and so on.

PVB thickness:0.38mm 0.76mm

PVB colour:clear ,yellow,red ,green,blue and so on

Glass thickness: 3-19mm

Sizes:

Max. Size: 2440x3660mm, can be cut as customers' request

Feature of Double Tempered Laminated Glass

1) safety

As the PVB glue is very toughness when the sandwich glass is broken as a result of external force ,the PVB glue coat will absorb a great deal of the impact energy and make it die away quickly ,consequently the PVB sandwich coat very difficult to be punctured and the glass can be maintained in the frame entirely and brings somewhat shading effect even if it suffers from cracks under the impact .viewed from such aspect , the sandwich glass is real safety glass.

2)Sound insulation

Because PVB glue processes a highly strong blockage effect to sound waves , the sound waves obviously weakened when passing the sandwich glass , reducing the noise interference suffered by work occasions or household living .

3)UV proofing

Having a highly good proofing effect to UV rays (the proofing ratio is higher than 90%)the valuable indoor furniture ,exhibits, arts and other artcles from fading as a result of influence of the UV rays.

Application

With unique characteristics ,the sandwich glass is widely adopted in artcles and occasions such as buildings grating , aloft grounds ,high-rank curtain walls windows and doors, furniture ,show windows, aquarium.

Laminated Glass Performance Levels according to Thickness

Glass Characteristic |

Thickness (mm) |

UV Transmittance (%) |

LT (%) |

3+0.38+3mm Clear |

6.38mm |

5 |

89 |

6+0.38+6mm Clear |

12.38mm |

3 |

86 |

6+0.38+6mm Reflective |

12.38mm |

0.5 |

22 |

Size

2440x3660mm, can be cut as customers' request

Thickness

6.38mm, 8.38mm 10.38mm, 12.38mm, 6.76mm, 8.76mm, 10.76mm, 12.76mm

MOQ

1 FCL

- Q: What material is the simulation tree made of?

- Usually according to different kinds of trees, there are many kinds of trees. Such as banyan cement, glass steel, really, there is fresh coconut tree trunk type is a reference material preservation, as we & apos. Therefore, the simulation tree generally does not specify a certain material.

- Q: What is the glass DV board made of?.

- The glass DV plate is made of glass and consists of two or more glass laminated glass.

- Q: What are the raw materials for making glass?

- Sandstone fused glass has a bright luster, and has a good transparency, acid resistance and mechanical strength.

- Q: Aluminum alloy window material is good, how to assemble?

- Sealing material: according to its different material, can be divided into structural sealant, building sealant (weather glue) and insulating glass two sealant. Structural sealant can be divided into one component and two components, two kinds. One component sealant, acid sealant and neutral sealant and so on. According to the method of fixing and fixing glass, the sealing material is divided into two kinds: dry material and wet material. When in use, the utility model can be used both inside and outside of the dry material, and can also be used for both inside and outside, and can be used in a mixed way. That is to say, when the outer side of the glass is arranged, the inner part of the glass is dry, and the outer part of the wet material or the inner side of the glass is provided with wet material for external use and dry. Dry material is finished product (market), according to its aluminum alloy notch in the form of different and divided into several kinds, soft and hard degrees are also different.

- Q: Which is the best solar water heater tube?

- There are three kinds of vacuum heat collecting tubes: high temperature pipe, high efficiency pipe and high cold pipe. High temperature pipe coating than ordinary length (from the nozzle is about 1cm), the tube of high temperature resistance, anti damping performance is particularly strong, the film on the 400 DEG C high temperature air drying condition, not aging, not falling, not color. The high efficiency pipe film is about 2.5cm apart from the pipe mouth. The tube is ultra high absorption, less heat loss, fast heating up and high thermal efficiency. The high temperature pipe has the advantages of high efficiency, high heat efficiency and fast heating, less heat loss, and hot water as usual under the condition of 30 DEG C. Consumers can choose different vacuum heat collecting tubes according to different areas.

- Q: How is glass made, raw material proportioning?

- The glass is the main component in the manufacturing process of quartz sand, quartz sand is combined with other chemical materials at high temperature (1300 degrees Celsius) crystallized after firing the cooling of the body, with a hard, abrasion resistance, corrosion resistance and high transmittance characteristics, its wide application has a long history.

- Q: Does the material of sunglasses choose good glass or plastic?

- There is almost no plastic for sun lenses, so it is better to use resin materials.Sunglasses are mainly made of two kinds of glass material and resin material.

- Q: What are the main materials for making glass?

- Silica is the main raw material made of silica on the earth reserves is great. Silica is the main raw material for the main raw material is made of glass stones. The silicon content of different rocks are different. In our life of these materials is the most common.

- Q: There are several ways of heating the industrial drying tunnel furnace and are different from each other?

- The utility model has the advantages of long service life and high reliability. The heater is made of special electric heating material, and the design power load is reasonable, and the heater adopts multiple protection, so that the safety and the service life of the heater are greatly increased.

- Q: Mobile phone film new flexible toughened glass membrane, really is the glass?

- Tempered glass (Temperedglass/Reinforcedglass) belongs to safety glass. Glass has a fairly good abrasion resistance and is very hard, with a Vivtorinox hardness of 622 to 701.

1. Manufacturer Overview

| Location | Hebei,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe South Asia |

| Company Certifications | CCC;CCESC |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Reflective Double Tempered Laminated Glass 6+0.38+6mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters m²

- Supply Capability:

- 1500 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords