Clear Tempered Glass with 3C/CE/ISO Certificate 3mm-19mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Clear Tempered Glass:

TEMPERED GLASS is made by heating flat glass to just below its softening temperature (650 °c) and suddenly chilling it with jets of cold air. It results in the outer skins under powerful compressive stress and the interior with severe tensile stress. In consequence, the impact applied to the glass will be overcome by the compressive stress on the surfaces to assure safety of use. It is ideal for areas with high wind loads and areas where human contacts are an important consideration.

2.Main features of Clear Tempered Glass:

.5 times harder than ordinary float glass, stronger resistance to thermal breakage than annealed or heat strengthened glass.

.Once breakage occurs, the glass disintegrates into small cubical fragments, which are relatively harmless to human body.

.It withstands abrupt temperature change of 220 Centigrade.

.Sizes are produced as per customer request. Once tempered, it can not be cut down.

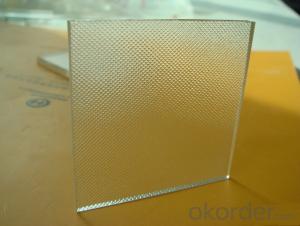

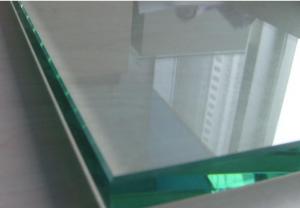

3.Clear Tempered Glass:

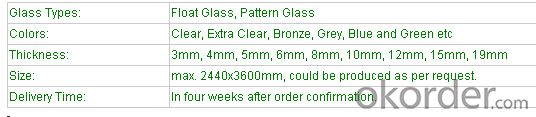

4.Clear Tempered Glass Specification:

5.Our factory

6.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the main raw materials for making ceramics, glass and cement?

- The main raw materials of cement clinker clinker production [four main raw materials (limestone, sandstone mainly provides Ca (mainly Si), alumina (or slag, mainly to provide Al (or Fe), iron slag, gypsum, slag etc.)]

- Q: Is toughened glass dish loaded with food harmful to human body?

- Taking into account the raw materials for the production of glass, as long as the regular manufacturers of products, do not worry about glass tableware precipitation problem is not to precipitate harmful products, but as the glass products, even tempered glass, the first priority is the safety problem, because even tempered glass, also has a certain rate of suicide therefore, strongly recommended the toughened glass into the use of microwave heating.

- Q: The main chemical constituents of ordinary glass

- The raw materials for making ordinary glass are soda ash, limestone and quartzThe composition of common glass chemical oxides (Na2O, CaO, 6SiO2), the main component is silica

- Q: What is the difference between white float glass and ordinary float glass?

- Ultra white is generally used in solar panels, raw materials, aluminum content higher

- Q: What is glass fiber reinforced nylon?

- With excellent wear resistance, heat resistance and electrical properties, high mechanical strength, self extinguishing, good dimensional stability, widely used in automotive industry products, textile products, pump impeller and first class precision engineering componentsPA6 enhancement series:With good wear resistance, heat resistance, oil resistance and chemical resistance, but also greatly reduce the water absorption and shrinkage of raw materials, with excellent dimensional stability and excellent mechanical strength

- Q: How to seal the glass fiber reinforced plastic mould?

- Considering the type of FRP mould surface is different from the rubber mold so complicated, is generally flat front, so it is recommended to do a Z type mold, pre buried iron screws for back. As long as the screw is properly distributed, it will not leak. Can again, in the mold a good brush coat, also a little gel in the mold parting surface, or glass glue or strips of clay on a concave groove (note the hardness of sludge in winter). The old mold leaks in detail and the sludge is blocked.

- Q: What is the raw material of glass glue?

- Glass glue is a single component elastic Acid Type RTV silicone sealant, with silicone rubber as the main raw material, adding reinforcing agent, crosslinking agent, accelerator, antioxidant, plasticizer, with advanced technology for the synthesis of one component room temperature vulcanized (RTV) sealant, resistance to atmospheric aging performance is good.

- Q: Tempered and reinforced glass

- Tempered glass is a safety glass. It is very small and won't cause serious damage when broken. Toughened glass does not belong to safety glass. Large pieces of debris can cause serious damage.

- Q: What are the characteristics of the gas flow in the flame space of a glass furnace?

- Ordinary glass plate glass, wire glass and quartz glass (also known as crystal glass) a molding. Wired glass as the quartz glass; only a raw material of sandstone or silica or quartz sand. Tempered glass is made of flat glass as raw material for re processing: the cut of the flat glass into the tempering furnace, heating to about 650 degrees, with cold air quenching, glass forming hardening - tempering. Accomplish!

- Q: What are the main materials for making glass?

- Glass material mainly has three parts: basic material, flux and colorant, and also includes decoloring agent, clarifying agent and corrosion inhibitor* basic materials for glass making

Send your message to us

Clear Tempered Glass with 3C/CE/ISO Certificate 3mm-19mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords