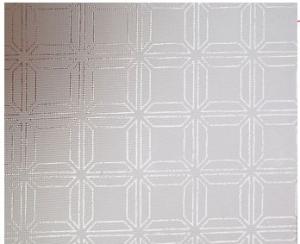

Clear Pattern Glass 3-8mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meter/Square Meters m²

- Supply Capability:

- 30000 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Model Number: HD

Function: Acid Etched Glass,Decorative Glass,Heat Reflective Glass,Insulated Glass

Shape: Flat

Structure: Solid

Technique: Clear Glass,Figured Glass,Laminated Glass,Tempered Glass

Type: Sheet

Glass clear patterned glass: white

Packaging & Delivery Of Clear Pattern Glass

Packaging Details: export seaworthy wooden crates with interlayer paper

Delivery Detail: within 15days after receive advance

Specifications

3-8mm clear patterned glass

Specification:1500*2000,1700*2000,1800*2000,1830*1200,1830*1830,1830*2134,1830*2440,2000*2500 ect.

Applications of Clear Pattern Glass:

patterned glass is widely used in indoor decroation such as in the public place but also required privace office,meeting room,hospital,bathing room and also widely used as surferce of furniture,shelf,lamp material .

Features of Clear Pattern Glass:

1) Rich and colorful pattern designs provide unique decorative results: or obscure and quiet,or sparkling and lively, or serious and elegant, or bold and generous.

2) Tangible stereoscopic patterns will never fade.

3)figured glass can be cut, ground, drilled, tempered, laminated and printed, etc.

Patterned glass

Thickness:3-8mm

Specification:1500*2000,1700*2000,1800*2000,1830*1200,1830*1830,1830*2134,1830*2440,2000*2500 ect.

patterns:Aqualite,Karatachi,Mistlite,Masterlite,Diamond,Galaxy,Millennium,Nashiji ect.

- Q: What kind of material is glass made of?

- We know that solid materials can be divided into two categories: organic materials and inorganic materials. Organic materials are wood, plastic, plexiglass, cotton, wool, nylon and so on. Inorganic materials can be divided into three categories: single crystal, polycrystal and glass according to the structure. A single crystal has regular shapes and strict rules, such as the ruby is an alumina single crystal, the crystal is a silica single crystal, and the diamond is a single crystal of carbon. Polycrystal is a collection of large amounts of small single crystals, and all kinds of ceramics and metals are polycrystalline materials. Glass is a noncrystalline solid obtained by melting, cooling, and curing. Its structure has certain rules (short-range order) in the atomic and molecular range, but there is no rule (long-range disorder) in the macroscopic range. It can be made into various shapes by moulds.

- Q: Is toughened glass dish loaded with food harmful to human body?

- Taking into account the raw materials for the production of glass, as long as the regular manufacturers of products, do not worry about glass tableware precipitation problem is not to precipitate harmful products, but as the glass products, even tempered glass, the first priority is the safety problem, because even tempered glass, also has a certain rate of suicide therefore, strongly recommended the toughened glass into the use of microwave heating.

- Q: Ceramic pots are sprayed glaze, or the whole porcelain crystallization good?

- Spray glaze workshop generally volatile material is relatively small, so, as long as a good protection, do not spray out of the glaze and lungs can be. Ceramic factory occupational disease is mainly pneumoconiosis, but now most of the ceramic dust prevention in this area is much better than before.

- Q: Cement / glass raw materials, equipment, principle, composition, characteristics, uses and types

- Ceramic composition used in high melting ceramics is used by manufacturers and is hardly used to make individual ceramic restorations. The material contains 75% to 85% feldspar, 12% to 22% quartz and 4% kaolin. Feldspar forms glass phases, and quartz remains suspended in the form of quartz after sintering. Quartz (SiO2) is used as an intensifier in ceramics. At normal sintering temperature, it has no structural change and plays a role in stabilizing the bulk (mass) at high temperatures.

- Q: What is the difference between white float glass and ordinary float glass?

- The iron oxide content of ultra white float glass is low, so the raw materials (sand or sandstone) to low iron content, iron content can be the best sand control below 0.03%

- Q: What are the raw materials of glass fiber reinforced plastic?

- The concept of composite material means that a material can not meet the use requirements, and needs to be composed of two or more than two materials together to form another material that can meet the requirements of people, that is composite material. For example, a single kind of glass fiber, although high in strength, but the fiber is loose, can only withstand tension, can not bear bending, shear and compressive stress, it is difficult to make a fixed geometry, is loose software.

- Q: Consult the experts on injection molding. Injection of raw materials Riga glass material, OK?

- There are many kinds of glass fiber material, such as PP, PA, ABS, PC and so on, which can be used according to needAdd different amounts of glass fiber

- Q: What kind of material is the toughened glass film made of mobile phone?

- General crystalline silicon photovoltaic components using glass and backplane package structure, but there are amorphous silicon photovoltaic components using double glass package. So the glass itself is a piece, commonly known as ultra low iron tempered white suede (suede also wove, back also double glass structure with flat glass)

- Q: What is the raw material of glass glue?

- Glass glue is a single component elastic Acid Type RTV silicone sealant, with silicone rubber as the main raw material, adding reinforcing agent, crosslinking agent, accelerator, antioxidant, plasticizer, with advanced technology for the synthesis of one component room temperature vulcanized (RTV) sealant, resistance to atmospheric aging performance is good.

- Q: What kind of glass material is used in the aquarium?

- Float glassClear float glass is a paste by the control gate into the tin groove, due to gravity and surface tension of molten tin floating on the surface after re entering the glass Lengcao Xu, smooth, corrugated and made to disappear. Dark green, smooth surface, no ripple, good perspective, with a certain toughness.

1. Manufacturer Overview

| Location | Hebei,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 32.00% South Asia 18.00% Mid East 12.00% South America 12.00% Domestic Market 12.00% Eastern Asia 9.00% Southeast Asia 5.00% Central America |

| Company Certifications | Business Lisence |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | xingang port,qingdao port |

| Export Percentage | |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Clear Pattern Glass 3-8mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meter/Square Meters m²

- Supply Capability:

- 30000 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords