Triple Tempered Laminated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters m²

- Supply Capability:

- 1500 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Function: Heat Absorbing Glass,Heat Reflective Glass

Shape: Flat

Structure: Solid

Technique: Clear Glass,Laminated Glass,Tempered Glass

Type: Float Glass

colour: clear,royal blue,ford blue,ocean blue,F-green

edge: finepolished

edge Interlayer: PVB

PVB thickness: 0.38mm0.76mm1.14mm1.52mm

Usage: building,windows,doors

PVB color: clear ,yellow,red ,green,blue and so on

Max size: 3660*2440mm

Min size: 300*300mm

certificate: ISO CCC

Packaging & Delivery of Triple Tempered Laminated Glass

Packaging Details: storng wooden crates with interlayer paper

Delivery Detail: within 15 days after receive deposit

Specifications of Triple Tempered Laminated Glass

1.Extremely high safety

2.Energy-saving building materials

3.Sound control

4.Ultra-violet resistance

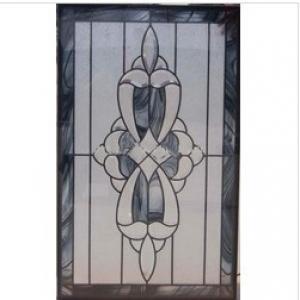

5.Decorative glass

Raw material

Float glass,Glaverbel glass,On-line coated glass,On line LOW-E,Off line LOW-E, On-line SUN-E and so on.

Color:clear,royal blue,ford blue,ocean blue,F-green,Green,dark grey,light grey,red bronze,golden bronze,and so on.

PVB thickness:0.38mm 0.76mm

PVB colour:clear ,yellow,red ,green,blue and so on

Glass thickness: 3-19mm

Sizes:

Max. Size: 2440x3660mm, can be cut as customers' request

Min size:300*300mm

Feature of Triple Tempered Laminated Glass

1) safety

As the PVB glue is very toughness when the sandwich glass is broken as a result of external force ,the PVB glue coat will absorb a great deal of the impact energy and make it die away quickly ,consequently the PVB sandwich coat very difficult to be punctured and the glass can be maintained in the frame entirely and brings somewhat shading effect even if it suffers from cracks under the impact .viewed from such aspect , the sandwich glass is real safety glass.

2)Sound insulation

Because PVB glue processes a highly strong blockage effect to sound waves , the sound waves obviously weakened when passing the sandwich glass , reducing the noise interference suffered by work occasions or household living .

3)UV proofing

Having a highly good proofing effect to UV rays (the proofing ratio is higher than 90%)the valuable indoor furniture ,exhibits, arts and other artcles from fading as a result of influence of the UV rays.

Application of Triple Tempered Laminated Glass

With unique characteristics ,the sandwich glass is widely adopted in artcles and occasions such as buildings grating,aloft grounds ,high-rank curtain walls windows and doors, furniture ,show windows, aquarium.Laminated Glass Performance Levels according to Thickness

Size:2440x3660mm, can be cut as customers' request

Thickness:6.38mm, 8.38mm 10.38mm, 12.38mm, 6.76mm, 8.76mm, 10.76mm, 12.76mm

MOQ:1 FCL

- Q: Which glass factory has good glass?

- If the original piece of glass with good quality of Qingdao Jin Jing, Jiangmen farun, TGI, CSG, luoyang.... These glass plants are relatively stable, and is a large enterprise, if the processing technology is good, it depends on the processing unit of the process, this is not recommended.

- Q: What are the main raw materials for making ceramics, glass and cement?

- The main raw materials for producing ceramics are clay (such as Suzhou soil), quartz, feldspar (potassium feldspar and albite)

- Q: Twilight wall hollow glass with glass Zha glue with what is best?

- Groove type aluminum single channel seal, because of its poor sealing, easy to enter moisture, resulting in condensation of glass, frosting, short service life, so that the hollow {TodayHot} glass gradually eliminated.

- Q: What are the paper made of? What is the glass made of? What is the plastic made of?

- The common (sodium) glass consists of a mixture of sodium silicate and calcium silicate with a small amount of silica and alumina. Usually made from a mixture of sand, sodium carbonate and calcium carbonate, and can be melted by a mixture of sodium sulphate and carbon instead of sodium carbonate.

- Q: Comparison of plexiglass steel bridge and inorganic glass steel bridge

- 4, can release harmful gases, human health and environmental protection have a certain impact. 5, high cost, but also a larger fluctuation of raw material prices. 6, after the waste is not easy to handle. Two, inorganic glass fiber reinforced plastics (referred to as Magnesium Oxide) advantages: 1, high temperature. (under normal circumstances, Fahrenheit temperature of 400 degrees Celsius, to maintain the product is not deformed), 2, anti-aging, 20 years without deformation of the product. 3. Purify the air and absorb carbon dioxide from the air. 4, high strength. 5, waterproof performance is good. 6, light weight, only in plexiglass.

- Q: What kind of mineral is glass made of?

- Colored glass is made by adding some metal oxides in the manufacture of ordinary glass. Cu2O - red; CuO - blue-green; CdO - pale yellow; CO2O3 - blue; Ni2O3 - dark green; MnO2 - purple; colloidal Au - red; colloidal Ag - yellow)

- Q: What does GF30 represent in plastic PP GF30?

- (PP) polypropylenePP-GF30 glass fiber reinforced polypropylene content of glass fiber 30%

- Q: Why are most of the chemical instruments made from glass?

- Because experiments require high temperatures, heating, freezing, and many complex processes of chemical reactions,

- Q: What material is used in the protective film in the middle of glass?

- Production process is:1: opening, the entire glass will be cut into a larger size than the molding of 0.6mm pieces.2:CNC carved, will open material scrap with steel sand grinding chamfering, drilling (or slot), after the end of CNC on the forming of the carved glass3, flat grinding, mainly to deal with the opening and CNC caused by surface scratches.4: cleaning, ultrasonic cleaning machine will be washed flour, while drying glass.5: tempering, the use of potassium acid to strengthen the glass, so that the stress of glass, strength, resistance and so on to meet certain requirements.6: cleaning: the tempered glass re-entry ultrasonic cleaning.7: stick ab8: packing finished products

- Q: What materials are needed for the production of glass bottles and what are their proportions?

- The manufacturing technology of the use of glass a thousand li a day, increasing by the clock, glass, doors and windows, lamps, such as high-tech electronic components and space technology, are indispensable glass. Our daily contact with most of the "flat glass is" thick to thin for doors and windows, clocks and the use of medical tests, the manufacturing method is that the furnace in the glass slurry level or traction method (also called float) and vertical traction method. After the dissolution of soluble traction after furnace also has the cooling system, cooling after the completion into a "flat glass, flat glass thickness mainly depends on the speed of traction, traction faster, can be manufactured and thinner. Although the ordinary flat glass from the front appears bright transparent, but from the side near the edge is slightly blue, because the amount of glass color depends on the main raw material in the manufacture of glass - quartz sand and iron content of purity. Generally, the thin glass used in the watch industry is superior in quality but expensive in value, mainly because the material used in quartz sand is superior and the iron content is very low (usually under 3/10000).

1. Manufacturer Overview

| Location | Hebei,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe South Asia |

| Company Certifications | CCC;CCESC |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Triple Tempered Laminated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters m²

- Supply Capability:

- 1500 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords