Clear Double Tempered Laminated Glass 6+0.38+6mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters m²

- Supply Capability:

- 1500 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Function: Heat Absorbing Glass,Heat Reflective Glass

Shape: Flat

Structure: Solid

Technique: Clear Glass,Laminated Glass,Tempered Glass

Type: Float Glass

colour: clear

edge: flat edge,grind edge,finepolished edge,bevelled edge

Packaging & Delivery of double tempered laminated glass

Packaging Details: storng wooden crates with interlayer paper

Delivery Detail: 7-15 days

Specifications of double tempered laminated glass

1 Safety

2 Strength for resistance to impact

3 Strength for resistance to human body5 Sound insulation

1) safety

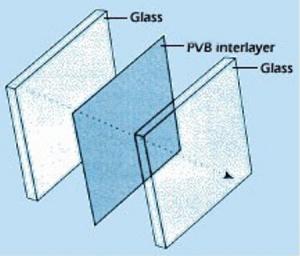

As the PVB glue is very toughness when the sandwich glass is broken as a result of external force ,the PVB glue coat will absorb a great deal of the impact energy and make it die away quickly ,consequently the PVB sandwich coat very difficult to be punctured and the glass can be maintained in the frame entirely and brings somewhat shading effect even if it suffers from cracks under the impact .viewed from such aspect , the sandwich glass is real safety glass.

2)Sound insulation

Because PVB glue processes a highly strong blockage effect to sound waves , the sound waves obviously weakened when passing the sandwich glass , reducing the noise interference suffered by work occasions or household living.

3)UV proofing

Having a highly good proofing effect to UV rays (the proofing ratio is higher than 90%)the valuable indoor furniture ,exhibits, arts and other artcles from fading as a result of influence of the UV rays.

4)application

With unique characteristics ,the sandwich glass is widely adopted in artcles and occasions such as buildings grating,aloft grounds ,high-rank curtain walls windows and doors, furniture ,show windows, aquarium.

Specification of double tempered laminated glass

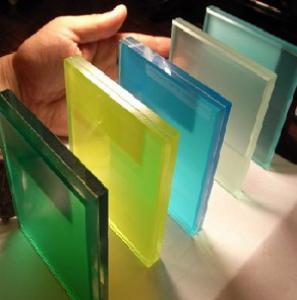

The color of PVB

(1) Euro grey

(2)light brozen

(3)dark blue

(4)green

(5)ocean blue

(6)F-green

(7)blue-green

(8)milky white

(9) light yellow

(10)chinese red

(11)purplish red

(12)orange

(13)clear

the type of glass

(1)clear float glass

(2)tinted glass

(3) reflective glass

Size

3300*2250mm,3300*2134mm,3210*2250,2440*1830mm,2440*1530 etc

Thickness

6.38mm,6.76mm,8.38mm,8.76mm,10.38mm,10.76mm,12.38mm,16.76mm etc

Laminated Glass Performance Levels according to Thickness

Glass Characteristic | Thickness (mm) | UV Transmittance (%) | LT (%) |

3+0.38+3mm Clear | 6.38mm | 5 | 89 |

6+0.38+6mm Clear | 12.38mm | 3 | 86 |

6+0.38+6mm Reflective | 12.38mm | 0.5 | 22 |

- Q: Chemical materials and additives needed for the production of glass

- The production process of float glass is introduced by taking ordinary production line of daily melting capacity of 600 tons in China as an example.Float glass is made in tin bath. The length of the whole production line is about 500 meters. It can produce 550 to 600 tons of glass every day. It is equivalent to 3 meters wide, 3 millimeters thick, and the glass belt is about 25 kilometers in length. Once started, 24 hours a day is uninterrupted until the furnace is stopped for about 8-10 years. Float production is the main mode of production of flat glass

- Q: What's the raw material for goldfish bowl?

- As for other containers: as long as you can hold water, do not fade, no smell, no harmful substances can be raised

- Q: Do solar panels use toughened glass, or are some high light transmitting materials good?

- There are ultra white solar glass. Dedicated to this solar energy

- Q: What's good with a cup?

- TIPS intimate tips: Mug divided into pure porcelain, porcelain, glass, plastic or stainless steel of these types of materials.

- Q: What are the raw materials for low dielectric glass fiber?

- Glass fiber is divided into different grades according to its composition, properties and uses. According to the provisions of the standard level (see table), E glass fiber is most widely used, widely used in electrical insulating materials; special fiber grade S, while the output is small, but very important, because it has super strength, mainly used for military defense, such as bullet proof box; C level more than E with chemical resistance in the battery isolation plate, chemical filter; a basic glass fiber reinforced materials used in the production.The main component of glass fibre and its main components are silica, alumina, calcium oxide, boron oxide, sodium oxide, Magnesium Oxide, depending on the amount of alkali content in glass, can be divided into non alkali glass fiber (Na2O 0% ~ 2%, which belongs to the aluminum borosilicate glass), glass fiber (8% ~ sodium sodium calcium silicate glass 12%, a boron containing or not containing boron) and high alkali glass fiber (Na2O 13%, sodium calcium silicate glass).

- Q: What are the raw materials made of glass and plastics?

- Polyethylene (Polyethylene, PE), referred to as PE. is ethylene organic polymer compound. Polyethylene is the best material in contact with food. Non-toxic, tasteless and odorless, conform to the hygiene standards of food packaging. Polyethylene film, transparent, with moisture, oxygen, anti acid and alkali resistance, air tightness in general, excellent heat sealing properties. Known as "plastic flowers" reputation. Plastic packaging and printing volume is the largest and most important materials.PVC-- PVC

- Q: Is the price of glass raw material the biggest proportion of quartz?

- The price of raw materials is the largest proportion of quartz sand.

- Q: The shell of glass steel electric cars will not be on the poor out of the glass Sizha?

- There are 2 kinds of process for making automobile shell with glass fiber reinforced plastic, 1. hand paste forming process and 2. pressing processThe choice of raw materials is reasonable, according to the operating procedures, the product is not defective, will not appear exposed fiber, it will not cause skin itchingA small number of unscrupulous manufacturers, technical level is low, Jerry built products must be betterYou can spray a layer of resin or a layer of dry adhesive tape on the exposed surface of the fiber when you encounter inferior products

- Q: What raw material is the front bumper of the car made of?

- The front bumper of the car is made of toughened glass.

- Q: What are the production processes and raw materials of float glass?

- Float glass production process refers to the glass liquid in molten metal floating on the surface of the flat glass production process. The production process of float glass is to select the raw material needed for the production of glass according to the designed glass composition, and weigh various raw materials according to the designed material, and then prepare the mixture by mixing.

1. Manufacturer Overview

| Location | Hebei,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe South Asia |

| Company Certifications | CCC;CCESC |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Clear Double Tempered Laminated Glass 6+0.38+6mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters m²

- Supply Capability:

- 1500 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords