Civil Works Material HDPE Geosynthetic Clay Liner(GCL)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Civil Works Material HDPE Geosynthetic Clay Liner(GCL)

1,Introduction

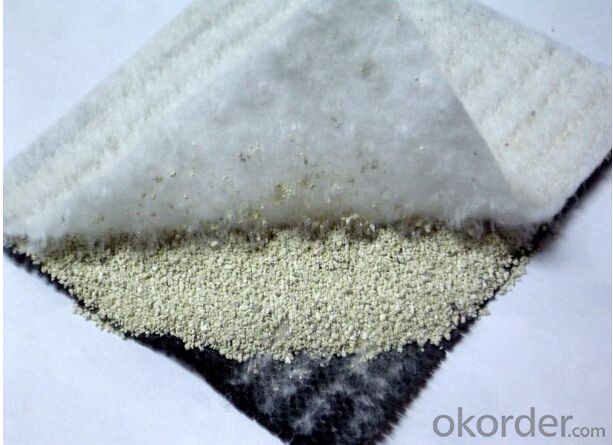

Our GCL is composed of 3 layers, the upper layer is nonwoven geotextile, while the lower layer is woven geotextile, natural sodium bentonite fills the gap between geotextile layers. The application with natural sodium bentonite can enlong the using life of construction. Our GCL creates a new green and environmental building material.

We have two kinds of GCL. One is GCL without HDPE layer, the other is HDPE GCL. For GCL, it is widely used in landfill, lagoon, river bottom, basement and so on. For HDPE GCL, it is used in subway, basement, tunnel, underground and projects, salt water area in harsh environment.

2,Features

1. Environment friendly

Our GCL is made of natural sodium bentonite, which contributes to good water proof quality, while causes no pollution to the environment. Its porosity guarantees the breath of biology.

2. Long-lasting waterproof performance

Natural sodium bentonite was formed billions of years ago. Its waterproof performance can last longer than building itself.

3. Easy application

Application of GCL is not constrained by weather. Connection and restore is easy to be finished.

3,Application

· Landfills | · Mud Pits |

· Lagoons | · Canals |

· Bund Lining | · Tank Lining |

· Fish Farm Lining | · Roof Lining |

· Waste Water Pits | · Ponds and Reservoirs |

· Dams | · Floating Covers |

· Vertical Cutoff Walls | · Hydraulic Structure |

· Basement Lining | · Drip Irrigation Ponds |

4,Specification of Geosynthetic Clay Liner(GCL) for anti-seepage

PROPERTIES | Test Method | Typical Value |

BENTONITE PROPERTIES | ||

Bentionite Swell Index | ASTM D 5890 | ≥24ml/2g |

Bentionite Fluid Loss | ASTM D 5891 | ≤18ml |

Finished GCL PROPERTIES | ||

Bentionite Mass/Unit Area | ASTM D 5993 | ≥3.6kg/sq.m |

Peel Strength | ASTM D 6496 | ≥400N/m |

Grab Strength | ASTM D 6768 | ≥6kN/m |

Thickness | ASTM D 5199 | ≥6mm |

Permeability | ASTM D 5084 | ≤5.0×10-11m/sec |

Index Flux | ASTM D 5887 | ≤1.0×10-8m3/m2/sec |

Geotextile PROPERTIES | ||

Non-Woven Geotextile Mass | ASTM D 5261 | ≥200g/sq.m |

Woven Geotextile Mass | ASTM D 5261 | ≥110g/sq.m |

ROLL DIMENSIONS | ||

Width | Normal | 5.8m |

Length | Normal | 30m |

Package | Normal | PE Film |

PROPERTIES | Test Method | Typical Value |

BENTONITE PROPERTIES | ||

Bentionite Swell Index | ASTM D 5890 | ≥24ml/2g |

Bentionite Fluid Loss | ASTM D 5891 | ≤18ml |

Finished GCL PROPERTIES | ||

Bentionite Mass/Unit Area | ASTM D 5993 | ≥3.6kg/sq.m |

Peel Strength | ASTM D 6496 | ≥400N/m |

Grab Strength | ASTM D 6768 | ≥6kN/m |

Thickness | ASTM D 5199 | ≥6mm |

Permeability | ASTM D 5084 | ≤5.0×10-11m/sec |

Index Flux | ASTM D 5887 | ≤1.0×10-8m3/m2/sec |

Geotextile PROPERTIES | ||

Non-Woven Geotextile Mass | ASTM D 5261 | ≥200g/sq.m |

Woven Geotextile Mass | ASTM D 5261 | ≥110g/sq.m |

ROLL DIMENSIONS | ||

Width | Normal | 5.8m |

Length | Normal | 30m |

Package | Normal | PE Film |

FAQ:

How many quantity for one 20'' container?

About 5,000m2, 16rolls

What's your delivery time?

About 15-20days against deposit received

. What's your package?

Per roll with two pieces woven bag

- Q: How can geocells be used in green roof systems?

- Geocells can be used in green roof systems by providing a stable and durable platform for vegetation growth. They are typically laid as a grid system on top of the roof, filled with soil, and planted with various types of vegetation. The geocells help to retain the soil, prevent erosion, and distribute the weight of the plants evenly across the roof. Additionally, they promote water drainage and can enhance the overall sustainability and environmental benefits of green roof systems.

- Q: Can earthwork products be used in coastal protection projects?

- Yes, earthwork products can be used in coastal protection projects. These products, such as geotextiles, geogrids, and geosynthetics, can be applied to reinforce and stabilize coastal slopes, prevent erosion, and provide protection against wave action. They are commonly used in the construction of breakwaters, revetments, and seawalls, helping to mitigate the impact of coastal hazards and ensure the long-term stability of coastal areas.

- Q: What are the weight limitations of earthwork products?

- The weight limitations of earthwork products can vary depending on the specific product and its intended application. However, in general, earthwork products such as geotextiles, geogrids, and geomembranes are designed to withstand heavy loads and can typically support weights ranging from a few hundred pounds to several tons. It is important to consult the manufacturer's specifications and guidelines to ensure that the weight limitations of a particular earthwork product are not exceeded to maintain its structural integrity and effectiveness.

- Q: How do earthwork products help with erosion control on slopes?

- Earthwork products, such as geotextiles, geomats, and erosion control blankets, play a crucial role in erosion control on slopes. These products are designed to stabilize soil and prevent erosion by reinforcing the ground and reducing water velocity. Geotextiles, for instance, act as a barrier that separates the soil layers, improving stability and preventing soil movement. Geomats, on the other hand, provide a protective layer that helps retain soil particles, while allowing water to flow freely. Similarly, erosion control blankets cover the soil surface, reducing the impact of rainfall and promoting vegetation growth. In summary, earthwork products help with erosion control on slopes by enhancing soil stability, reducing water velocity, and promoting vegetation growth.

- Q: How do earthwork products contribute to sound barrier construction?

- Earthwork products, such as soil, gravel, and rocks, play a crucial role in sound barrier construction. These materials are used to build embankments or berms, which act as physical barriers to absorb, reflect, and redirect sound waves. By strategically placing and shaping these earthwork products, sound barriers can effectively reduce noise pollution from highways, railways, or other sources, enhancing the overall acoustic environment and improving the quality of life for nearby communities.

- Q: The relationship between material development and civil engineering development

- The emergence and development of new materials to promote the human society and history, civilization, progress. Material is the material basis of human production and life, is the direct driving force of social development. The development of materials and its application is an important milestone in human civilization and social progress

- Q: Material in the role of civil engineering in which should be the main understanding

- 7, the establishment of material analysis files (price, supply) timely feedback decision to build the five members of the work of the staff is mainly the contents of these materials in the work of the staff in a more important position. But also an indispensable part of construction.

- Q: How are geosynthetic clay liners installed in landfill projects?

- Geosynthetic clay liners (GCLs) are installed in landfill projects by first preparing the subgrade with proper compaction and ensuring a smooth and even surface. The GCL is then unrolled and laid over the subgrade, with overlapping edges to create a continuous barrier. The liner is secured in place using anchor trenches or other mechanical means. Finally, the GCL is covered with a protective layer, such as a geotextile or a geomembrane, to prevent damage and enhance its performance.

- Q: How do segmental retaining walls provide stability?

- Segmental retaining walls provide stability through their unique design and construction. These walls are built using interlocking concrete blocks or stones that are stacked together in a specific pattern. This design allows for the transfer of lateral earth pressure from the backfill to the wall structure, preventing soil movement and maintaining stability. Additionally, these walls are reinforced with geogrids or steel reinforcements, which further enhance their strength and resistance to external forces. Overall, the combination of interlocking blocks and additional reinforcements ensures that segmental retaining walls can effectively retain soil and provide long-term stability.

- Q: Can earthwork products be used for constructing walkways and pathways?

- Yes, earthwork products can be used for constructing walkways and pathways. Earthwork products such as gravel, crushed stone, and sand can be used as base materials for walkways and pathways, providing stability and a solid foundation. Additionally, geotextiles can be used to reinforce the soil and prevent erosion in areas with heavy foot traffic.

Send your message to us

Civil Works Material HDPE Geosynthetic Clay Liner(GCL)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords