Geotextile 2m HDPE Geotextile Membrane Liner for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

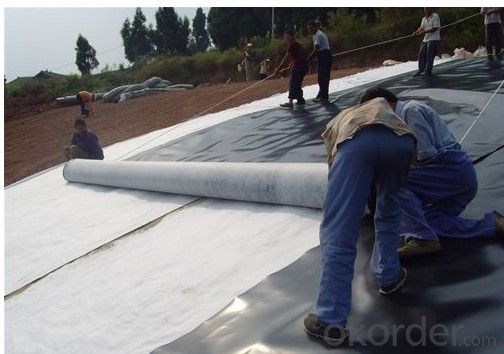

1. Product Introduction

Thickness

1mm-3.0mm

width

4-9m

Length

50-100m or as customers' requests

Material

LDPE, LLDPE, HDPE, EVA, ECB, PVC , CPE

Color

Black, white, green, blue, red, grey, and others

Port

Qingdao

Delivery

2-20 days

Packing

woven bag or as customers' requests

Technical specifications of HDPE geomembrane:

a) Density ≥ 0.94g/m2

b) Tensile Strength ≥25Mpa

c) Elongation at Break ≥ 550%

d) Right-angled Tear ≥ 110N/mm

e.)Puncture Strength ≥ 550N

f.) Permeability Coefficient ≤1.0xe-13g.cm/(cm2.S.Pa)

g.) -70oC Low Temperature Impact Brittle Property: good.

h.) Chemical Resistance: at 80oC, marinated in 5g/L Nacl for a long time, it will not erode or swell.

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used for separation of different soil layers?

- Yes, geotextiles can be used for the separation of different soil layers. Geotextiles are permeable fabrics that can be placed between different soil layers to prevent mixing and maintain their distinct properties. They act as a barrier, allowing water to pass through while preventing the migration of fine particles. This separation helps in enhancing the stability and performance of the soil layers, reducing the risk of settlement and maintaining the integrity of the construction project.

- Q: How do geotextiles help in the reinforcement of soil?

- Geotextiles help in the reinforcement of soil by providing a stable and strong layer that enhances the soil's mechanical properties. They act as a barrier against soil erosion, distribute loads more evenly, and improve the overall stability and strength of the soil.

- Q: How are geotextiles different from other geosynthetic materials?

- Geotextiles are a type of geosynthetic material that is specifically designed to provide filtration, separation, and reinforcement functions in civil engineering projects. Unlike other geosynthetic materials such as geogrids or geomembranes, geotextiles are primarily used for their filtration properties, allowing water to pass through while retaining soil particles. They are typically made from synthetic fibers, which give them high tensile strength and durability. Overall, geotextiles serve a distinct purpose within geosynthetic materials, focusing on filtration and soil stabilization applications.

- Q: Can geotextiles be used in soil erosion control on construction sites?

- Yes, geotextiles can be used in soil erosion control on construction sites. Geotextiles are permeable fabrics that can be placed on the soil surface to prevent erosion by stabilizing the soil and allowing water to pass through while retaining sediment. They are effective in controlling erosion, reducing sediment runoff, and maintaining soil integrity during construction activities.

- Q: How to determine the nominal breaking strength of filament spunbonded nonwoven geotextile

- You can use a dedicated geotextile strong test machine detected.

- Q: I'm looking for the fabric that goes between gravel and the ground (for a gravel driveway).

- you can get this at wicks do it all (now focus) or any good building merchants

- Q: What are the challenges associated with the installation of geotextiles?

- Some challenges associated with the installation of geotextiles include ensuring proper alignment and placement of the fabric, securing it to the ground to prevent shifting or movement, and properly overlapping and connecting multiple pieces of geotextile to create a continuous barrier. Other challenges may include dealing with uneven or unstable soil conditions, working in difficult terrain or access areas, and ensuring the geotextile does not get damaged during the installation process. Additionally, the selection and installation of appropriate anchoring methods and the need for specialized equipment or expertise can also pose challenges.

- Q: How do geotextiles help in reducing the risk of slope failures?

- Geotextiles help in reducing the risk of slope failures by providing reinforcement and stabilization to unstable slopes. These materials are placed within the slope to increase its strength and prevent erosion. Geotextiles also help in promoting water drainage and filtration, which reduces the build-up of hydrostatic pressure within the slope. Overall, geotextiles enhance the stability of slopes and mitigate the potential for landslides or slope failures.

- Q: Can geotextiles be used in reservoir lining projects?

- Yes, geotextiles can be used in reservoir lining projects. Geotextiles are commonly employed to improve the stability and performance of reservoir linings by providing reinforcement, filtration, and separation functions. They can effectively prevent soil erosion, control seepage, and enhance the overall integrity and longevity of the reservoir lining system.

Send your message to us

Geotextile 2m HDPE Geotextile Membrane Liner for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords