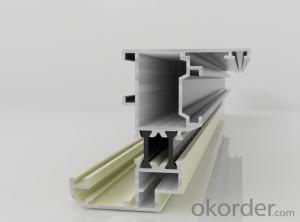

China Powder Coated Aluminum Profiles - Manufacturing Aluminium Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium profile

1) Alloy: AA6061, AA6063

2) Temper: T5, T6

3) Series of surface treament:

1. Mill Finished

2. Anodizing: Silver, champagne, light bronze, dark bronze, black, light titanium, dark titanium.

3. Electrophoretic Coating: Silver, champagne, bronze, black, light bronze, dark bronze.

4. Electrostatic Color Powder Coating: Normal color, special color.

5. Fluorocarbon Powder Spraying: Normal color, special color.

6. Wood Grain Coating: Import paper, domestic paper.

- Q: Do aluminum profiles have good thermal insulation properties?

- Aluminum profiles, unfortunately, lack good thermal insulation properties. Due to its high conductivity, aluminum readily permits heat transfer. Consequently, when it comes to preventing heat transfer and providing thermal insulation, aluminum profiles are less efficient compared to materials like wood or vinyl. To improve the thermal insulation capabilities of aluminum profiles, they are frequently combined with thermal breaks or insulating materials. This combination serves to minimize heat loss or gain.

- Q: Can aluminum profiles be used in curtain wall systems?

- Yes, aluminum profiles can be commonly used in curtain wall systems. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for constructing curtain walls. Its versatility allows for various design options and structural support, making it a popular choice in the construction industry.

- Q: Can aluminum profiles be used for DIY projects or home improvement?

- Yes, aluminum profiles can be used for DIY projects or home improvement. Aluminum profiles are versatile and can be easily cut, shaped, and joined together to create various structures and components for different applications. They are lightweight, yet strong and durable, making them suitable for a wide range of projects. Whether you want to build a custom shelving unit, construct a garden fence, create a frame for a solar panel, or even design a unique piece of furniture, aluminum profiles can be an excellent choice. Additionally, they are resistant to corrosion and require minimal maintenance, which makes them ideal for outdoor projects as well. With the right tools and a little creativity, aluminum profiles can be transformed into functional and aesthetically pleasing additions to your home.

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum profiles in the construction of roofs.

- <p>Aluminum profiles in roofing offer several advantages, including their lightweight nature which reduces structural load, high corrosion resistance making them suitable for various climates, and ease of installation which can lower labor costs. They also have a long lifespan and can be recycled, contributing to sustainability. However, there are disadvantages such as higher initial costs compared to traditional materials, potential for dents or damage from impacts, and the need for regular maintenance to preserve their finish and prevent fading. Additionally, aluminum can be noisy during rain or hail, and it may not be as thermally efficient as some other roofing materials, potentially requiring additional insulation.</p>

- Q: Are there any limitations on the length of aluminum profiles?

- Yes, there are limitations on the length of aluminum profiles. The length of aluminum profiles is typically limited by factors such as the manufacturing process, transportation constraints, and practicality. In terms of manufacturing, aluminum profiles are usually extruded or rolled, and the length is limited by the equipment and capabilities of the manufacturer. Extrusion presses and rolling mills have certain size limitations, which determine the maximum length of aluminum profiles that can be produced. Transportation constraints also play a role in limiting the length of aluminum profiles. Longer profiles may be difficult to transport due to logistical challenges, such as the size of trucks or shipping containers. Moreover, the risk of damage or deformation during transportation increases with longer profiles. Practicality is another factor that imposes limitations on the length of aluminum profiles. Longer profiles may become less rigid and more prone to sagging or bending under their own weight, making them less suitable for certain applications. Additionally, longer profiles may be more difficult to handle and install, requiring specialized equipment and techniques. While there are limitations on the length of aluminum profiles, manufacturers can often produce profiles in various lengths to meet specific project requirements. However, it is important to consider these limitations and consult with the manufacturer to determine the feasibility of producing longer profiles if needed.

- Q: The user is inquiring about the efficiency of aluminum profile recycling in their region and seeks details on how it can be done.

- <p>Yes, aluminum profiles can be recycled efficiently in most regions due to their high value and the relatively low energy required for recycling. The process typically involves collection, sorting, melting, and recasting into new aluminum products. To recycle aluminum profiles in your region, you can check for local recycling centers or scrapyards that accept aluminum. Some municipalities also have curbside recycling programs that include aluminum. Ensure that the profiles are clean and free of non-aluminum components before recycling to maximize their value and efficiency in the recycling process.</p>

- Q: This question asks for an explanation of various methods used to manufacture aluminum profiles, which are long, extruded shapes made from aluminum.

- <p>Aluminum profiles are manufactured using several processes, primarily extrusion, but also including casting, rolling, and machining. Extrusion is the most common method, where aluminum is heated and forced through a die to create a desired shape. Casting involves pouring molten aluminum into molds to form specific profiles. Rolling is used to produce flat sheets or plates, which can then be further processed. Machining involves cutting and shaping aluminum using tools like lathes and mills. Other processes include forging, which deforms aluminum under high pressure, and powder metallurgy, where aluminum powder is compacted and sintered into a solid profile. Each process has its advantages and is chosen based on the desired profile shape, strength, and application.</p>

- Q: Can aluminum profiles be anodized for improved corrosion resistance?

- Yes, aluminum profiles can be anodized to enhance their corrosion resistance. Anodizing creates a protective oxide layer on the surface of the aluminum, making it more resistant to corrosion and increasing its durability.

- Q: Explain the advantages of utilizing aluminum profiles in the construction industry.

- <p>Aluminum profiles offer several benefits in construction, including high strength-to-weight ratio, which means they are strong yet lightweight. This reduces the load on structures and facilitates easier handling and installation. They are also corrosion-resistant, ensuring longevity and low maintenance costs. Aluminum profiles are recyclable and environmentally friendly, contributing to sustainable construction practices. Their malleability allows for versatile design and customization, accommodating various architectural needs. Additionally, they have excellent thermal conductivity, which can be beneficial for heat management in buildings. Lastly, their aesthetic appeal and modern look enhance the visual appeal of construction projects.</p>

- Q: What kinds of profiles are made of aluminium alloy windows?

- Four, look at the materialMaterial in the material, there are 6 main areas of reference:The thickness: Aluminum Alloy sliding window of 70 series, 90 series two, Aluminum Alloy housing interior sliding doors with 70 series. The number of aluminum alloys indicates the number of millimeters of the thickness of the door frame. Common aluminum alloy sliding window has 55 series, 60 series, 70 series, 90 series of four kinds. Selection should be based on the window size and the local wind pressure value is determined as shall be not less than 70 series Aluminum Alloy closed balcony sliding window.The strength: tensile strength should be 157 per square millimeter of Newton, yield strength to reach 108 per square millimeter of Newton. When buying, you can moderate bending profiles, and then you should be able to restore the original state.3: the same color Aluminum Alloy profile color should be consistent, such as color, that is not to buy.The flatness: check the Aluminum Alloy profile surface, should not sag or bulge.The gloss: avoid buying Aluminum Alloy doors and windows opening on the surface of the bubble (white) and ash (black), crack, burr, profile leather and other obvious defects.The oxidation degree of oxide film thickness should reach 10 micron. When choosing, light the surface of the profile to see if the oxide film on the surface can be removed.

Send your message to us

China Powder Coated Aluminum Profiles - Manufacturing Aluminium Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords