China Jushi Fiberglass Chopped Strand Mat Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

China Jushi Fiberglass Chopped Strand Mat Supplier

Introduction:

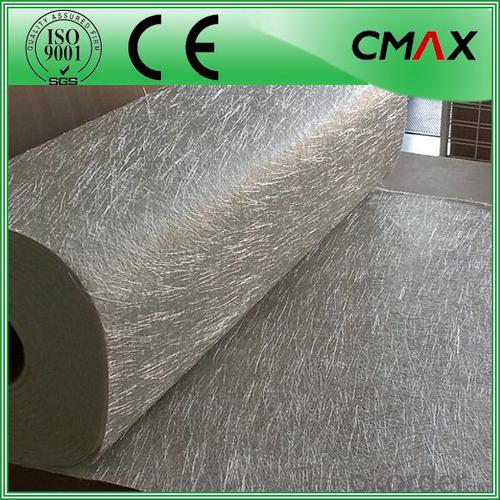

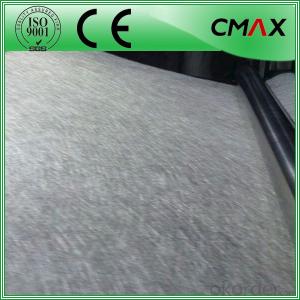

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

1. Uniform density ensures consistent fiberglass content and mechanical properties of the composites products.

2. Uniform powder distribution ensures good mat integrity, little loose fibers and small roll diameter.

3. Excellent flexibility ensures good mold ability with no spring back at sharp angles.

4. Fast and consistent wet-out speed in resins and rapid air lease reduce resin consumption and production cost and enhances productivity and mechanical properties of the end products.

5. The composite products have high dry and wet tensile strength and good transparency.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

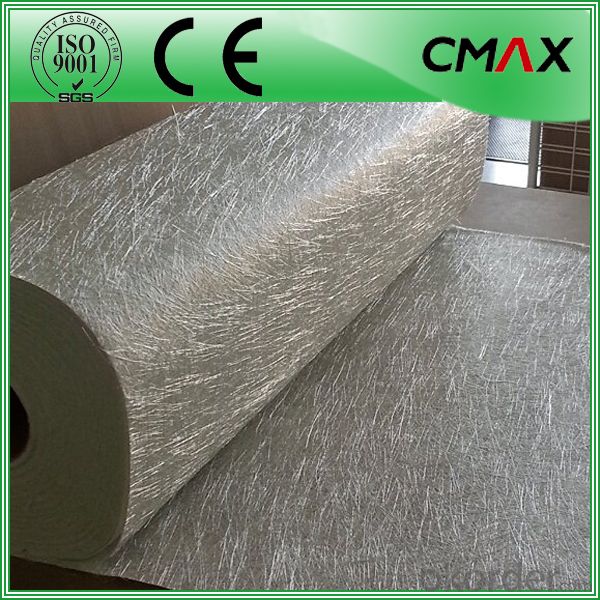

Products Shows:

Certificates:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton.

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing black glass fiber in construction projects.

- <p>Black glass fiber offers several advantages in construction, such as high strength and durability, making it ideal for reinforcement. It is also resistant to corrosion and has excellent electrical insulation properties. Additionally, it is lightweight, which can reduce the overall weight of structures. However, it has some disadvantages, including its brittleness, which can lead to breakage under certain conditions. Black glass fiber can also be harmful to health if inhaled, necessitating proper handling and safety measures. Moreover, it is not as flexible as some other materials, which may limit its use in certain applications.</p>

- Q: Is it possible to utilize black fiberglass tissue as a flooring material in high-rise constructions?

- <p>Yes, black fiberglass tissue can be used for flooring in high-rise buildings. It is known for its high strength, durability, and resistance to various environmental factors. Fiberglass tissue is often used in composite materials and can be combined with other materials to create a strong and stable flooring solution. However, it's crucial to ensure that the specific type of fiberglass tissue meets the necessary safety standards and building codes for high-rise construction, as well as to consider its fire resistance and load-bearing capabilities.</p>

- Q: Is it appropriate to utilize black fiberglass tissues for cleaning up liquid spills on hard surfaces?

- <p>Yes, you can use black fiberglass tissues for wiping up spills on hard surfaces. They are designed to be strong and absorbent, making them suitable for cleaning up liquids. However, it's important to ensure that the hard surface is not damaged by the abrasiveness of the fiberglass. Always test on a small, inconspicuous area first to confirm it's safe. Additionally, be cautious as black tissues may leave fibers or color transfer on light-colored surfaces.</p>

- Q: Is it possible to utilize black fiberglass tissue as an insulating material within vehicles?

- <p>Yes, black fiberglass tissue can be used for insulation in vehicles. It is known for its heat-resistant properties and is commonly used in automotive applications to insulate engine compartments and exhaust systems. Fiberglass provides thermal insulation, reduces noise, and protects against heat damage. However, it's important to ensure that the fiberglass used meets specific automotive standards for safety and performance.</p>

- Q: What are the most effective steps to adhere a black fiberglass tape to a wall or ceiling?

- <p>The best way to install a piece of black fiberglass tape on a wall or ceiling involves preparing the surface, applying the tape, and securing it properly. First, clean the area thoroughly to remove dust and debris. Then, cut the fiberglass tape to the desired length. Apply a high-quality adhesive specifically designed for fiberglass to the back of the tape. Press the tape firmly onto the surface, starting from one end and smoothing it out to remove any air bubbles. Use a putty knife or your fingers to press firmly and evenly. Let the adhesive dry according to the manufacturer's instructions before handling or applying any weight to the tape.</p>

- Q: Is it possible to utilize black fiberglass tissue in residential settings?

- <p>Yes, black fiberglass tissue can be used in residential applications. It is commonly utilized for insulation purposes, providing thermal and acoustic insulation. Black fiberglass is also used in the construction of walls, ceilings, and roofs to enhance energy efficiency and reduce noise pollution. However, it's important to ensure that it is installed correctly and safely, as improper handling can lead to health issues due to the potential release of fiberglass fibers.</p>

- Q: What is the standard thickness measurement for black fiberglass paper towels?

- <p>The thickness of black fiberglass paper towels can vary depending on the manufacturer and the specific product. Generally, these towels are known for their durability and thickness compared to standard paper towels. However, without a specific product reference, it's challenging to provide an exact measurement. Typically, they might range from 0.1 to 0.5 millimeters in thickness, but for precise information, one should refer to the product specifications or contact the manufacturer directly.</p>

- Q: What is the coefficient of thermal expansion for black fiberglass tissue, which measures how much the material expands per degree of temperature change?

- <p>The coefficient of thermal expansion (CTE) for black fiberglass tissue is approximately 0.5 to 1.0 x 10^-5 per degree Celsius. This value indicates that for every degree Celsius increase in temperature, the material expands by 0.000005% to 0.00001%. The exact value can vary depending on the specific composition and manufacturing process of the fiberglass tissue.</p>

- Q: Is it permissible to use black fiberglass tissue in the construction or components of food processing equipment?

- <p>Black fiberglass tissue is not typically used in food processing equipment due to concerns about food safety and contamination. Fiberglass can potentially shed particles that could contaminate food products. Instead, food processing equipment usually employs materials that are food-grade and non-reactive, such as stainless steel, which is both durable and safe for contact with food. It's crucial to use materials approved for food contact to ensure the safety and quality of the food products.</p>

- Q: What are the uses of black fiberglass tissue in the construction industry?

- <p>Black fiberglass tissue, also known as black glass fiber cloth, is widely used in construction for its heat resistance, strength, and durability. It is commonly used as a reinforcement material in cementitious materials, such as in the production of GRC (Glass Reinforced Concrete) panels and other composite materials. It can also be used as a fire-resistant barrier in walls and ceilings, and for insulation purposes. Additionally, it is employed in the creation of lightweight and strong structures, such as in the construction of roofs and facades, due to its high tensile strength and low weight.</p>

Send your message to us

China Jushi Fiberglass Chopped Strand Mat Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords