Fiberglass Mat Tissue Chopped Strand Mat Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Chopped Strand Mat Made In China

Introduction:

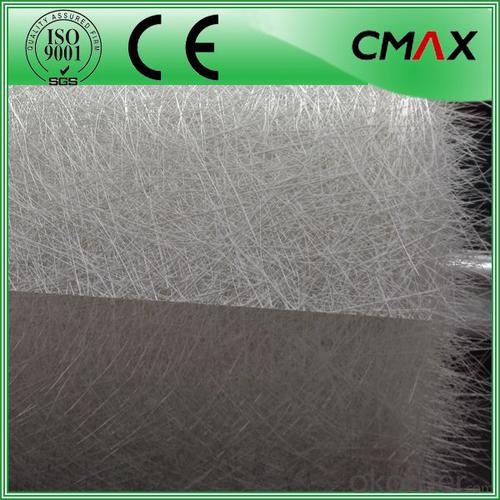

Chopped Strand Mat is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the application by hand lay-up FRP moldings, such as, various sheets and panels, boat hulls, boat tubs, cooling towers, corrosion resistant, vehicles, etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

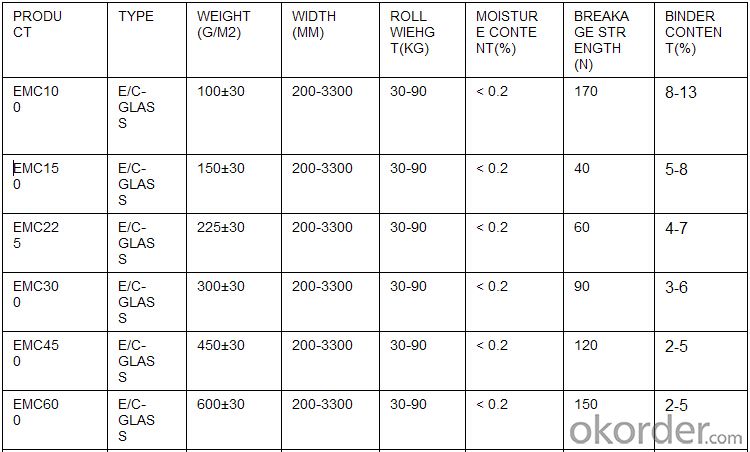

Technical Data:

Packaging:

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Can fiberglass mat tissue be used for repairing fiberglass structures?

- Yes, fiberglass mat tissue can be used for repairing fiberglass structures. Fiberglass mat tissue is a versatile material that is commonly used in the construction and repair of fiberglass structures. It is designed to provide strength, stability, and reinforcement to the damaged areas of the structure. The mat tissue is typically applied with resin, which helps to bond the fibers together and create a durable repair. It is especially effective for repairing cracks, holes, and other types of damage in fiberglass surfaces. Overall, fiberglass mat tissue is an excellent choice for repairing fiberglass structures due to its strength, flexibility, and ability to conform to various shapes and sizes.

- Q: Is fiberglass mat tissue safe to handle?

- Fiberglass mat tissue is generally considered safe for handling, but it is crucial to take specific precautions to reduce potential risks. This material consists of delicate glass fibers that, if mishandled, can become airborne and cause skin, eye, and respiratory irritation. To ensure safety, it is recommended to wear personal protective equipment like gloves, safety goggles, and a dust mask while handling fiberglass mat tissue. This will prevent direct contact with the fibers and inhalation of loose particles. Working in a well-ventilated space is also advised to lower the concentration of airborne fibers. Additionally, careful handling is essential to avoid physical injuries. The fibers can be sharp and cause cuts or abrasions if not handled properly. It is advisable to use appropriate tools and techniques when cutting, shaping, or manipulating the material. Proper disposal is equally important when dealing with fiberglass waste. Sweeping or vacuuming the area where fiberglass mat tissue was handled should be avoided, as it can disperse fibers into the air. Instead, opt for damp cleaning methods or specialized vacuum cleaners with HEPA filters to contain the fibers and minimize exposure risks. By adhering to these safety precautions and handling guidelines, the potential dangers associated with fiberglass mat tissue can be effectively minimized, ensuring safe handling and use of the material.

- Q: How does the fiber distribution of fiberglass mat tissue affect its strength?

- The fiber distribution of fiberglass mat tissue has a significant impact on its strength. The strength of fiberglass mat tissue is primarily derived from the fibers embedded within the material. These fibers provide reinforcement and help to distribute stress and load evenly across the surface. The distribution of fibers in fiberglass mat tissue refers to how the fibers are arranged and oriented within the material. If the fibers are evenly distributed, with a uniform arrangement and orientation, the strength of the fiberglass mat tissue will be enhanced. This uniform distribution allows for efficient load transfer from one fiber to another, leading to improved overall strength. On the other hand, if the fiber distribution is uneven or random, with fibers clumped together or oriented in different directions, the strength of the fiberglass mat tissue will be compromised. Uneven distribution can result in stress concentrations at certain areas, leading to weak points and potential failure under load. Furthermore, the fiber length and density also play a role in determining the strength of fiberglass mat tissue. Longer fibers provide greater reinforcement and improve the overall tensile strength of the material. Additionally, a higher fiber density, meaning more fibers per unit area, increases the strength and overall performance of the fiberglass mat tissue. In summary, the fiber distribution of fiberglass mat tissue directly affects its strength. A uniform and evenly distributed arrangement of fibers enhances the material's strength by facilitating efficient load transfer, while an uneven or random distribution compromises its strength by creating stress concentrations and weak points. Additionally, the fiber length and density also contribute to the overall strength of the fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for insulation boards?

- Yes, fiberglass mat tissue can be used for insulation boards. Fiberglass mat tissue is a lightweight, flexible material made from fine glass fibers bonded together with a resin. It has excellent thermal insulation properties, making it an ideal choice for insulation boards. The mat tissue can be easily cut to fit various shapes and sizes, and it can be used to insulate walls, roofs, floors, and other areas of a building. It is also resistant to moisture, mold, and mildew, ensuring long-lasting insulation performance. Additionally, fiberglass mat tissue is fire-resistant, further enhancing its suitability for insulation applications. Overall, fiberglass mat tissue is a versatile and effective material for insulation boards.

- Q: Can fiberglass mat tissue be used in high-temperature applications?

- No, fiberglass mat tissue cannot be used in high-temperature applications.

- Q: Can fiberglass mat tissue be used for roofing?

- Yes, fiberglass mat tissue can be used for roofing. It is commonly used as a reinforcement material for roofing systems due to its high strength and durability. It helps to enhance the structural integrity of the roof and improve its resistance to weathering and other external factors.

- Q: How does the surface finish of fiberglass mat tissue affect its adhesion to resin?

- The surface finish of fiberglass mat tissue can significantly affect its adhesion to resin. The surface finish refers to the texture or smoothness of the fiberglass mat tissue. In general, a rougher surface finish tends to provide better adhesion to resin. This is because a rough surface provides more surface area for the resin to adhere to, allowing for a stronger bond. Rougher surface finishes can be achieved through various manufacturing techniques, such as using coarser fibers or adding texturizing agents during production. On the other hand, a smoother surface finish may result in weaker adhesion. A smooth surface does not provide as much surface area for the resin to bond with, leading to a weaker and less durable bond. Smoother surface finishes can be achieved by using finer fibers or through additional processing steps to smooth out the surface. It is important to consider the specific application and requirements when choosing the surface finish of fiberglass mat tissue. For applications that require high strength and durability, a rougher surface finish may be preferred to ensure optimal adhesion to the resin. Conversely, for applications where a weaker bond is acceptable or where a smoother surface finish is desired for aesthetic reasons, a smoother surface finish may be chosen. Ultimately, the surface finish of fiberglass mat tissue plays a critical role in determining the adhesion to resin. It is essential to select the appropriate surface finish to achieve the desired strength, durability, and performance in various applications.

- Q: Does fiberglass mat tissue have any fire-resistant properties?

- Fiberglass mat tissue indeed possesses fire-resistant properties. Its composition of glass fibers and a thermosetting resin inherently grants it fire resistance. When subjected to high temperatures or flames, fiberglass mat tissue resists ignition and combustion, instead hindering flame propagation and aiding fire containment. As a result, fiberglass mat tissue proves suitable for fire protection necessities in various applications, including insulation, fire barriers, and fireproof panels. Nevertheless, it is crucial to acknowledge that although fiberglass exhibits fire resistance, it remains susceptible to melting or burning in extreme circumstances.

- Q: Can fiberglass mat tissue be used for repairing automotive parts?

- Yes, fiberglass mat tissue can be used for repairing automotive parts. It is commonly used in automotive repairs as it provides strength and durability to the repaired area. The mat tissue can be applied with resin to reinforce damaged or weakened sections of automotive parts, making it an effective solution for repairing various components.

- Q: What are the different types of fiberglass mat tissue available in the market?

- There are several types of fiberglass mat tissue available in the market, including chopped strand mat (CSM), continuous filament mat (CFM), and surfacing mat. Chopped strand mat is made up of randomly oriented short glass fibers held together with a binder, providing good strength and conformability. Continuous filament mat consists of long continuous glass fibers, providing higher strength and stiffness. Surfacing mat, on the other hand, is a thin layer of fiberglass mat used to improve the surface finish and appearance of the final product.

Send your message to us

Fiberglass Mat Tissue Chopped Strand Mat Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords