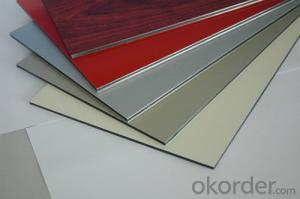

China Colored Aluminum Sheets for Truck Use Aluminum Coil for Truck Body Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

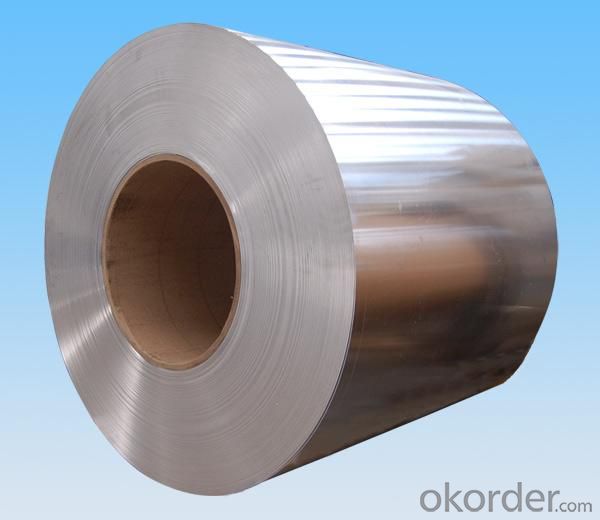

Truck Use Aluminum coil for Truck Body Panel

Hot-rolled High Quality Low Price Aluminum Coil is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

Temper: O, F, HXX

Thickness: Thickness

Width: 1000-1500mm

Type: Coil/Roll

Surface Treatment: mill finished

Application: Decoration, packaging, printing, covering

Standard size: Upon customer's demand

Quantity: 18tons(±10%)in one 20 feet container

Specification:

Hot Rolled Aluminium coil | ||||||||||||||||

Aluminium Coils, non-alloy and alloy products have many different applications, they are used windly throughout construction, building, decoration, lighting, metal nameplate, aircraft and aerospace structures, etc. | ||||||||||||||||

Specification | ||||||||||||||||

ALLOY | TEMPER | THICKNESS | WIDTH(mm) | LENGTH(mm) | ||||||||||||

1050,1060,1070, | O,F, H12, 114,H18,H22, H24,H26,H32, H34,H36,H111, | 3.0-10.0 | 1000--1500mm | in Coil | ||||||||||||

chemical composition | ||||||||||||||||

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Min.Al | |||

1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.50 | |||

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.60 | |||

1070 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | - | 0.05 | 0.03 | 0.03 | 99.70 | |||

1100 | 0.95 | 0.05-0.2 | 0.05 | - | - | - | 0.10 | - | - | - | 0.05 | 99.00 | ||||

3003 | 0.60 | 0.70 | 0.5-0.2 | 1.0-1.5 | - | - | - | 0.10 | - | - | - | 0.15 | 96.95-96.75 | |||

3004 | 0.30 | 0.70 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | - | - | - | 0.15 | 96.55-95.55 | |||

Packaging detail: First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with dry agent ,without fumigation, wooden pallets

Delivery detail: Within 25days

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

- Q: I am doing a report on machining aluminum and characteristics of aluminum and can not find what the 6061 stock stands for. Looked all over library, internet, etc.

- The spec for 6061 aluminium, can be found on this link - 66.102.9.104/search?q=cache:ALU5S...

- Q: What are the different alloys available for aluminum sheets?

- Aluminum sheets offer a range of options when it comes to alloys, each with its own distinct properties and uses. Let's take a look at some of the most commonly used alloys: 1. 1100: This alloy is pure aluminum and boasts exceptional resistance to corrosion. It is perfect for applications that demand high levels of protection against corrosion, such as marine environments. 2. 3003: Another alloy that is purely aluminum, 3003 offers good formability, moderate strength, and high resistance to corrosion. It finds its place in general sheet metal work, chemical equipment, and cooking utensils. 3. 5052: Known for its impressive fatigue strength and outstanding resistance to corrosion, especially in saltwater settings, this alloy is often employed in marine applications, as well as aircraft components and fuel tanks. 4. 6061: As a heat-treatable alloy, 6061 showcases excellent weldability and formability, along with elevated strength and superb corrosion resistance. It is commonly utilized in structural components like frames, railings, and automotive parts. 5. 7075: This alloy stands out for its remarkable strength-to-weight ratio, making it perfect for aerospace applications and structural components that face high levels of stress. However, it is less resistant to corrosion than other alloys and may require protective coatings in specific environments. These examples represent only a fraction of the aluminum sheet alloys available. The choice of alloy relies on the specific requirements of the application, considering factors such as strength, corrosion resistance, formability, and cost. It is crucial to consult a knowledgeable supplier or engineer to determine the most appropriate alloy for your particular needs.

- Q: I have no idea, and I can't figure this out, and neither can my aunt and she's super smart. It's this project that's due on Monday, and if I can't get it turned in, then I get detention and a failing lab grade. The only information I have is it's $2.96 for a roll of aluminum, it contains 2.96 square meters, and it weighs .995 grams...

- This can be done, as crazy as it sounds. Aluminum has a molar mass of 26.98g and the stated sample (the roll) is $2.96 for 0.995g You would divide 0.955 by 26.98. This gives you 0.0369, which is the amount of moles of aluminum in the roll. Then you need to use Avogadro's number. This is 6.02*10^23, and is the amount of particles in a mole. Avogadro's number multiplied by 0.0369 gives you 2.22138*10^22. This is the amount of aluminum atoms in the roll. Now, you divide the price ($2.96) by the amount of aluminum atoms (2.22138*10^22) to get the price per atom. Price per atom of aluminum in the stated sample: $1.332505*10^-22 (This is equivalent to .$0.0000000000000000000001332505) I hope this helps.

- Q: So my new farrier comes out tomorrow and charges $20 more for aluminum shoes and I was wondering why that is? Is one better than the other? My horse is a TB hunter jumper. Tell me what you think :)

- According to my farrier, aluminum shoes are harder to put on because they are softer than steel and they are easier to damage while shaping them for your horse's foot. He also says that aluminum shoes wear down faster than steel shoes, so if you are working a horse in a highly competitive sport, it's better to put steel shoes on. Most racehorses have aluminum shoes put on simply because they're lighter, but if you don't want to be changing the shoes every two weeks, or can't afford to, then steel shoes are the best way to go.

- Q: Can aluminum sheets be used in food packaging?

- Yes, aluminum sheets can be used in food packaging. Aluminum is a common material choice for food packaging due to its excellent barrier properties, durability, and ability to maintain the freshness and quality of food products. It is also lightweight, recyclable, and resistant to moisture, odors, and UV light.

- Q: The radius of an atom of aluminum is 143pm and there are 10^12 in a meter. The aluminum is a 3x3cm square. The density is 2.70 g/cm^3. I found the mass to be 0.03g. I found the volume to be 0.09cm^3

- Good quality standard aluminum foil such as Reynolds brand is 0.007 inches thick. If aluminum atoms are indeed 143 picometers in radius then the foil would be 2,486,713 atoms thick. Of course, the thickness is not controlled to a tolerance of one atom. (Cheaper brands are about 0.0060 to 0.0065 inches thick.) The ionic radius of aluminum is commonly accepted to be 72 pm, and as of 2008 a covalent radius of 121 pm. . .

- Q: What is the thickness range of aluminum sheets?

- The thickness range of aluminum sheets can vary depending on the specific application and industry standards. However, commonly available aluminum sheets typically range in thickness from 0.006 inches (0.15mm) to 0.25 inches (6.35mm). For more specialized applications, thicker aluminum sheets may be available. It is important to note that different alloys and grades of aluminum may have different thickness ranges, so it is essential to consult the specific requirements and standards of the intended use case.

- Q: Can aluminum sheet be used for electrical conductivity applications?

- Yes, aluminum sheet can be used for electrical conductivity applications. Aluminum has good electrical conductivity properties, making it suitable for various electrical applications such as wiring, connectors, and conductive components.

- Q: Iron is extracted from iron oxide by displacement with carbon.But aluminum is not extracted from aluminium oxide using displacement by carbon. Suggest a reason for this.

- Well, de facto because the heat of formation of aluminum oxide is so much greater than the heat of formation of iron oxide. If you're looking for something more mechanistic, find Al and Fe in the periodic table. Al and Fe are in different rows, and Fe is larger than Al, so although Al+3 and Fe+3 have the same charge, oxygen bonds less strongly to Fe+3 than to Al+3 because it's further away from the nucleus of Fe. Al+3 has no outer shell electrons at all; 3s, 3p, and 3d subshells are all empty. It's effectively a charged sphere with nothing to interfere with bonding. Fe+3 (as in hematite, Fe2O3) is larger, has filled 3s and 3p subshells, and a half-filled 3d subshell. That 3d electron density projects pretty far out into space, holding oxygen at arms length. Aluminum has no electron density in 3d orbitals, so oxygen can tuck in nice and tight and get a good grip. Any of these hit the mark? I don't know what background you're bringing to this question.

- Q: what's the difference between aluminum sheet detergent and central air-condition detergent?

- Central air condition cleaning includes air-cooled condenser cleaning and water-cooling condenser cleaning, if it’s air-cooled condenser cleaning, you can use aluminum sheet detergent.

Send your message to us

China Colored Aluminum Sheets for Truck Use Aluminum Coil for Truck Body Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords