China Black Aluminum Coil for ACP - Color Coated Aluminum Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

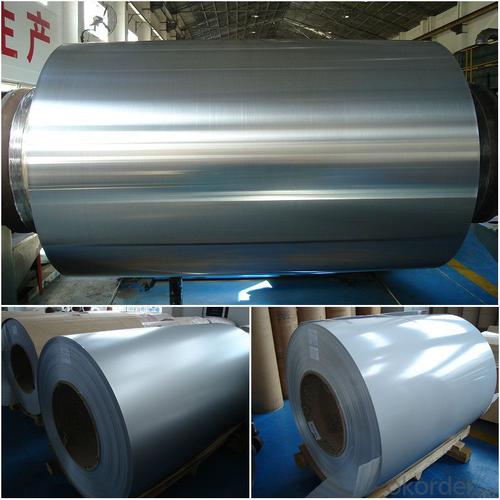

Color coated aluminum coil isa material with excellent acid-resistance and alkali-resistance. The coating layeris even with bright color to last for a very long time. It is a greendecoration material with the characters of environment protection,flame-resistance, and groovy colors. In nowadays, the color coatedaluminum coil has become the popular material for top grade decoration. With our advance professional aluminum coated technique, wecan custom various aluminum coils ,like coated aluminum coil , Color coatedaluminum coil , embossed aluminum sheet with the color and size which youdemands.

1)Process: pre-treatment, continuous painting and baking for times .

2)Material: high quality material, aluminum sheets from South West AluminumIndustry Company in China, pre-treatment material from Henkel & Chemtellfrom Germany, more than 70% of PVDF coating from PPG Corp., the USA andpolyester from Sweden Becker Industrial Coating Co., Ltd.

3) Ourproducts can keep excellent quality and stability.

4)Thickness: 0.06 - 1.0mm; width: 20 - 1,590mm

Applications:

The aluminum coils are widely used in ACP/curtainpanel/honey comb panel/shutter/roofing and most of the decoration areas. Withthe superior quality and advanced management, our products had been export toEuro/North America /East Asia and many other areas and countries.

PEAluminum Coating Coils for ACP

Featuresof PE Aluminum Sheet:

1.Adopting precision rolling coating technology, our PVDF and PE coated coil canensure excellent adhesive without coating omission.

2. For thePE coated aluminum coil we produced, there are various colors for your choice.

3. Usinginfrared heating technology to protect environment from pollution.

4. Ourcoated aluminum coil has four-roller coating line, uniform coating thicknessand good features.

RawMaterial of the PE Aluminum Coating Coils:

1. Aluminum Coil: high strength aluminum withalloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005according to customer)

2. Surface Paint: PE, PVDF and specialpaints.

Specification of PE Aluminum Coating Coil

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

PE coated aluminum coil is processed throughthe technics of roller coating and baking with precise polyester paints. Itscolor is glossy and with variety of colors enabling you to choose easily.Chromatic aberration is small, impact resistance is strong and easy to beprocessed, and all its performance has reached or surpassed the nationalcriteria. The products are widely used in indoor and door decoration, ceilings,room surface tiles, corrugated boards, wallpanels, advertisement boards, counters, home appliances, decoration in and outof autos and boats.

Performance of thecoating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Color of Card

PE (polyester)

PE

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q: Can aluminum coils be used in the manufacturing of appliances?

- Yes, aluminum coils can be used in the manufacturing of appliances. Aluminum is a lightweight and durable material that is commonly used in the manufacturing industry due to its excellent thermal conductivity and corrosion resistance properties. These properties make it suitable for various applications, including the production of heating and cooling systems in appliances such as refrigerators, air conditioners, and ovens. Aluminum coils are often used in these appliances to transfer heat efficiently and ensure optimal performance. Additionally, aluminum is a sustainable material as it is highly recyclable, making it an environmentally friendly choice for appliance manufacturers.

- Q: Can aluminum coils be used in the production of kitchen utensils?

- Kitchen utensils can indeed incorporate aluminum coils in their production. Aluminum is a favored material for kitchen utensils owing to its lightweight nature, durability, and ability to conduct heat. Aluminum coils are effortlessly malleable, allowing them to take on various forms and designs for utensils like pots, pans, baking trays, and even cutlery. Moreover, aluminum possesses resistance against corrosion, making it a suitable choice for contact with food and liquids. Nevertheless, it is essential to keep in mind that aluminum utensils may require a non-stick coating or a protective layer to prevent any adverse reactions with acidic or alkaline foods. Ultimately, owing to their adaptability and practicality, aluminum coils are extensively employed in the production of kitchen utensils.

- Q: How do aluminum coils contribute to the energy efficiency of products?

- Aluminum coils play a vital role in enhancing the energy efficiency of various products. To begin with, aluminum is renowned for its exceptional thermal conductivity, which facilitates efficient heat transfer. This characteristic enables aluminum coils to swiftly and effectively move heat between different components within a product, such as air conditioning systems or refrigerators. By efficiently dissipating heat, aluminum coils assist these products in operating more efficiently, reducing energy consumption, and ultimately saving costs for consumers. Furthermore, aluminum possesses the advantage of being a lightweight material, making it easier to incorporate into various products without adding unnecessary burden. This is particularly advantageous for industries like automotive and aerospace, where reducing weight is crucial for enhancing fuel efficiency. Through the use of aluminum coils in these applications, manufacturers can create lighter and more energy-efficient vehicles or aircraft, resulting in decreased fuel consumption and emissions. Moreover, aluminum coils offer exemplary resistance to corrosion. This is especially beneficial for products exposed to moisture or harsh environments, as it prevents rust and deterioration over time. By maintaining the performance and integrity of the coils, the overall energy efficiency of the product is preserved, ensuring optimal operation for an extended duration. In conclusion, aluminum coils make a significant contribution to the energy efficiency of products through their thermal conductivity, lightweight characteristics, and corrosion resistance. By effectively transferring heat, reducing weight, and preventing degradation, these coils facilitate the more efficient operation of products, leading to lower energy consumption, cost savings, and a reduced environmental impact.

- Q: What is the thermal conductivity of aluminum coils?

- Compared to other metals, aluminum coils exhibit a relatively high thermal conductivity. With approximately 237 W/m·K, aluminum possesses excellent heat conduction capabilities. This particular attribute renders aluminum coils well-suited for situations necessitating efficient heat transfer, like heat exchangers or air conditioning systems. The remarkable thermal conductivity of aluminum enables rapid and effective dissipation of heat, thereby guaranteeing optimal performance and energy efficiency across diverse industrial and residential environments.

- Q: Explain the relationship between aluminum coil and aluminum alloy in a few sentences.

- <p>Aluminum coil and aluminum alloy are related in that aluminum coil can be made from aluminum alloy. An aluminum alloy is a material composed of aluminum and other metallic or non-metallic elements, which are mixed to enhance its properties. Aluminum coils are long, rolled sheets of aluminum that can be made from various types of aluminum, including alloys. The use of an alloy allows for the creation of aluminum coils with specific characteristics, such as increased strength, corrosion resistance, or formability, depending on the application requirements. Thus, aluminum coils are often manufactured from aluminum alloys to meet the demands of diverse industries.</p>

- Q: Can aluminum coils be used in power generation facilities?

- Yes, aluminum coils can be used in power generation facilities. Aluminum is a highly conductive material that offers several advantages for power generation applications. It has excellent thermal conductivity, meaning it can efficiently transfer heat away from the coils, which is crucial for cooling systems in power generation facilities. Additionally, aluminum is lightweight, making it easier to handle and install compared to other metals like copper. This lightweight property also reduces the overall weight of the equipment, resulting in cost savings. Furthermore, aluminum is corrosion-resistant, which is important for power generation facilities that often operate in harsh environments. Overall, aluminum coils are a viable option for power generation facilities due to their conductivity, thermal efficiency, lightweight nature, and corrosion resistance.

- Q: Yep a slogan...the element Aluminum

- Aluminium - Wrap **** in it

- Q: Can aluminum coils be used in the production of aluminum composite roofs?

- Yes, aluminum coils can be used in the production of aluminum composite roofs. Aluminum coils are commonly used as the raw material for manufacturing aluminum composite roofs due to their lightweight, durability, and resistance to corrosion. The coils are typically processed and shaped into panels that are then used as the outer layer of the composite roof system, providing excellent protection against weather elements and ensuring long-lasting performance.

- Q: Does anyone know of any men's deodorant that doesn't contain aluminum? It has to be strong, as I do sweat a lot.

- Both my Speed Stick Original Scent and Old Spice High Endurance Original contain no Aluminum. They are both deodorants, NOT antiperspirants, which work differently. Deodorants do not inhibit sweating, they just keep you from smelling funky from it. Hence the name DEodorant. Antiperspirants on the other hand DO inhibit sweating as well as keep you smelling fresh. They do so by clogging your pores! And if there is aluminum in it, it can cause irritation on some people. Most antiperspirants contain aluminum, most deodorants do not. Whichever you end up going with just read the back label.

- Q: Can aluminum coils be used in the production of automotive parts?

- Yes, aluminum coils can be used in the production of automotive parts. Aluminum is a lightweight and durable material, making it suitable for various automotive components such as body panels, engine parts, and heat exchangers. Its corrosion resistance and excellent thermal conductivity also make it a popular choice in the automotive industry.

Send your message to us

China Black Aluminum Coil for ACP - Color Coated Aluminum Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords