China 3003 Coated Aluminum Coil - Yellow Coil Coating Aluminium Coils for ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Yellow Coil Coating Aluminium Coils for ACP Description

• Product: Aluminim coils

• Application:

corrugated roofs, outer walls, ovens, electrically controlled cabinets.

household appliances, transportation, base plate, color coating.

industrial freezers in the residential and industrial buildings.

refrigerator backplane, gas stove, air conditioner, microwave, LCD border.

• Advantage: Full production line with all kinds of coils supply

2. Main Features of the Yellow Coil Coating Aluminium Coils for ACP

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

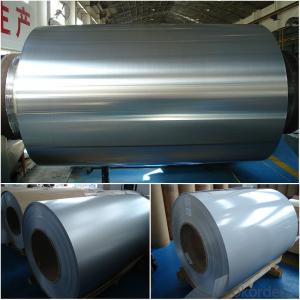

3. Yellow Coil Coating Aluminium Coils for ACP Images

4. Yellow Coil Coating Aluminium Coils for ACP Specification

Alloy | AA1050/1100/3003/3005/3105/5005/5052 etc |

Thickness | 0.03mm—4.0mm |

Width | 10mm—1600mm |

Coating | PVDF, PE |

Coatingthickness | Usually16-25 micron, could be 33-40 micron |

Color | According to Ral |

Standard | ASTM-B 209 GB/3008-2006 |

Usage/ApplicationsCoated Aluminum Coil/Sheet | Constructionand decoration, electronic appliances, lighting decoration, air-condition airpipe, sandwich panels and drainage, etc |

5.FAQ of Yellow Coil Coating Aluminium Coils for ACP

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: Can aluminum coils be customized to specific requirements?

- Yes, aluminum coils can be customized to specific requirements. The customization process involves adjusting the dimensions, thickness, alloy composition, and surface finish of the coils to meet the specific needs of different industries and applications.

- Q: What are the potential environmental impacts of aluminum coil production?

- The potential environmental impacts of aluminum coil production include deforestation due to the extraction of bauxite, water pollution from the chemicals used in the refining process, air pollution from the release of greenhouse gases during smelting, and energy consumption, as aluminum production requires a significant amount of electricity. Additionally, the disposal of waste materials and by-products can contribute to soil contamination if not managed properly.

- Q: What are the common applications of aluminum coils?

- Aluminum coils are widely used in various industries due to their unique properties and versatility. Some of the common applications of aluminum coils include: 1. HVAC Systems: Aluminum coils are extensively used in air conditioning and refrigeration systems, where they play a crucial role in heat transfer. The lightweight and excellent thermal conductivity of aluminum make it an ideal choice for these applications. 2. Transportation Industry: Aluminum coils are commonly used in the automotive and aerospace industries. They are used to manufacture radiators, condensers, evaporators, and other heat exchange components in vehicles. The high strength-to-weight ratio of aluminum helps in reducing the overall weight of the vehicle, leading to improved fuel efficiency. 3. Construction Sector: Aluminum coils find extensive use in the construction industry. They are used in the production of gutters, downspouts, roofing, and cladding materials. Aluminum's corrosion resistance and durability make it a preferred choice for outdoor applications that require long-lasting performance. 4. Electrical Industry: Aluminum coils are used in the production of cables and wires due to their excellent electrical conductivity. They also find use in transformers and power distribution systems. 5. Packaging Industry: Aluminum coils are widely used in the packaging industry. They are used to produce various types of packaging materials, such as cans, foils, and containers. Aluminum's ability to form a barrier against moisture, light, and oxygen makes it ideal for preserving the freshness and quality of food and beverages. 6. Marine Applications: Aluminum coils are used in the marine industry for manufacturing boats, ships, and other offshore structures. Aluminum's resistance to corrosion in saltwater environments makes it a suitable choice for these applications. 7. Industrial Equipment: Aluminum coils are utilized in various industrial equipment, including heat exchangers, condensers, and evaporators. Their thermal conductivity and corrosion resistance properties make them suitable for efficient heat transfer. In summary, aluminum coils have a wide range of applications across multiple industries, including HVAC, transportation, construction, electrical, packaging, marine, and industrial equipment. Their lightweight, excellent thermal conductivity, corrosion resistance, and durability make them a preferred choice for various applications.

- Q: Hey! I have an Aluminum MacBook (2.4 GHz Core 2 Duo, 9400m graphics processor), and I'm wondering whether it's worth updating to the new 2011 13 MacBook Pro. I'm mainly looking for two things: 1. What would be the difference between the 2.4 GHz Core 2 Duo, and the 2.3 GHz i5, and 2. What would be the difference between the 9400m and the HD 3000 Graphics?Thanks! :)

- The macpro is the better machine, but for most people the difference would be negligible. your aluminum is still MORE than good enough for almost all people. What are you using it for? If you're into CAD, by all means upgrade. But if you're just surfing the net, save your money. HD3000 is actually worse graphics, but the rest of the machine is better EDIT: AGAIN, it depends on what you are using it for!!! Despite using additional details, you never once discussed how it is to be used. If you read the post, it says, for most people the difference would be negligible. IF your needs are resource intensive, you might need to replace it. If your needs are not resource intensive, you can save your money. For example, I don't need to buy a new car every year, I usually make it last 5-6 years. But my computing requirements are high enough where I replace my laptops every two years and desktops alternating years so I always have a machine that is less than a year old. MOST people squeeze 4 or more years out of a computer. If you are a general ed, humanities or undeclared your aluminum would suit you just fine thgouh your lower 2 years even though it is older. You could then get a new computer for your upper division. If you were a engineering or architecture student, I'd upgrade after first year courses, If you're in business or engineering, get a PC, if you're in architecture, journalism, music or design get a mac. Any other major, it really doesn't matter. Good luck in school!

- Q: I have a aluminum sign that I store in the garage and it got a couple specks of rust on it which I don't like because I use it for my DJ shows. How can I get rid of the rust before it gets too bad without painting over it?

- Aluminum doesn't rust.

- Q: Is it possible to utilize a press machine to bend aluminum coils?

- <p>Yes, you can use a press to bend aluminum coils. Presses are versatile machines capable of bending various materials, including aluminum. However, it's crucial to select the appropriate press type and size for the specific coil dimensions and desired bend. Additionally, ensure the press has the necessary tonnage to handle the bending force required for aluminum. Using the right dies and lubrication can also improve the bending process and prevent damage to the coils. Always follow safety guidelines and consult with equipment specifications to ensure the press is suitable for bending aluminum.</p>

- Q: what is aluminium toxic amount on a human's general physiological system? and what is the usual amount aluminium injested?thankyou

- It is estimated that the normal person takes in between 3 and 10 milligrams of aluminum per day. Aluminum is the most abundant metallic element produced by the earth. It can be absorbed into the body through the digestive tract, the lungs and the skin, and is also absorbed by and accumulates in the bodies tissues. Aluminum is found naturally in our air, water and soil. It is also used in the process of making cooking pots and pans, utensils and foil. Other items such as over the counter pain killers, anti-inflammatory products, and douche preparations can also contain aluminum. Aluminum is also an additive in most baking powders, is used in food processing, and is present in antiperspirants, toothpaste, dental amalgams, bleached flour, grated cheese, table salt, and beer, (especially when the beer is in aluminum cans). The biggest source of aluminum, however, comes from our municipal water supplies. Aluminum is excreted by the kidneys, therefore toxic amounts can impair kidney function. Aluminum can also accumulate in the brain causing seizures and reduced mental alertness. The brain is normally protected by a blood-brain barrier, which filters the blood before it reaches it. Elemental aluminum does not pass easily through this barrier, but certain compounds contained within aluminum, such as aluminum fluoride do. Interestingly, many municipal water supplies are treated with both aluminum sulfate and aluminum fluoride. These two chemicals can also combine easily in the blood. Aluminum fluoride is also poorly excreted in the urine.

- Q: Automotive aluminum coil, using GB H22, what brand, what are the main ingredients?

- 5754-H22 aluminum sheet has the characteristics of medium strength, good corrosion resistance, weldability and easy processing. It is a typical alloy in Al-Mg (mg Al alloy) alloy. In the corresponding foreign brands for AlMg3, 5754 different heat treatment is the automobile manufacturing industry (car door, mould, seals), main materials used for canning industry

- Q: So i like eating frozen foods like wings or bagel bites and i cook them in my toaster oven with aluminum foil under them on top of the tray. I heard using aluminum is bad for you and can get you diseases or illnesses. Is this true and should i stop using aluminum foil? i eat these frozen foods maybe 3-4 times a week

- Almost everyone says aluminum is completely safe. And yet no one can explain where the aluminum comes from in the brains of alzheimers patients. The human body does not produce aluminum. There are those who say it comes from our cookware and deodorants. A slow build up in the brain over many years. Is it true? I don't know. I'm not a scientist and I don't play one on TV. I do know that we switched over to all cast iron and steel some years ago and only buy deodorants without aluminum.

- Q: What is the maximum operating temperature for aluminum coils?

- The maximum operating temperature for aluminum coils typically ranges from 200 to 250 degrees Celsius.

Send your message to us

China 3003 Coated Aluminum Coil - Yellow Coil Coating Aluminium Coils for ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords