Perforated Aluminum Checkered Sheet AA1100 for Automotive Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Five Bar Checkered Aluminum Sheet AA1100 for Automotive Body

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Five Bar Checkered Aluminum Sheet AA1100 for Automotive Body

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Five Bar Checkered Aluminum Sheet AA1100 for Automotive Body

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

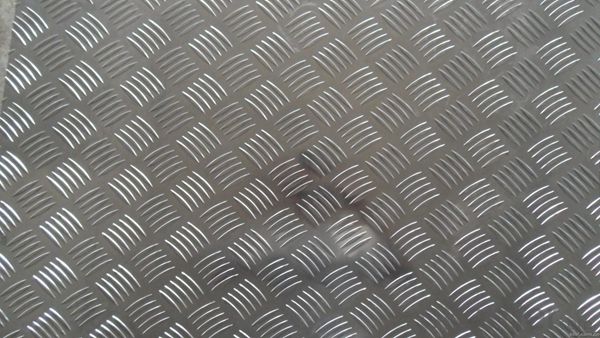

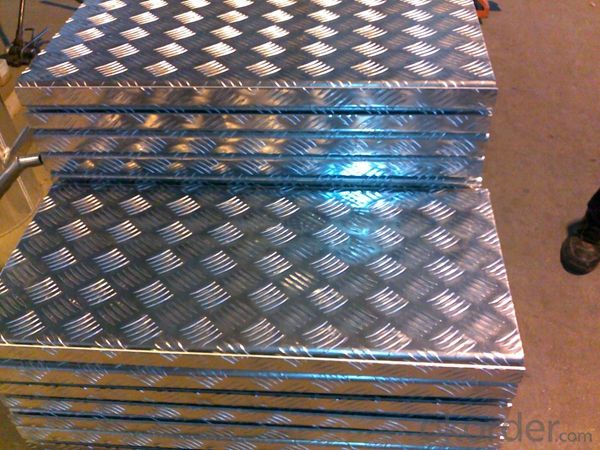

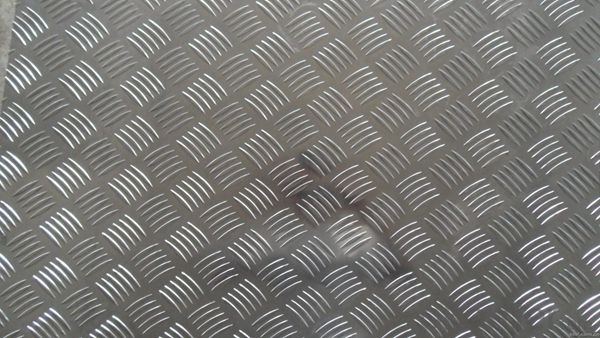

5. Image of Five Bar Checkered Aluminum Sheet AA1100 for Automotive Body

6. Package and shipping of Five Bar Checkered Aluminum Sheet AA1100 for Automotive Body

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Okay, so i swallowed some aluminum foil like the size of a quarter from my fruit rollup wrapper, ha don't ask why? but my stomach KINDA hurts right now...like 2 minutes later.. Could this have done any damage to me.?

- lol... You should be fine. But it may hurt a little coming out the other end? I don't know. One thing I do know: I swallowed a penny when I was a child and never had any trouble.

- Q: Are aluminum sheets suitable for roofing?

- Indeed, aluminum sheets prove to be a fitting choice for roofing purposes. Renowned for its lightweight nature, durability, and corrosion resistance, aluminum stands out as a favored material in the roofing industry. Moreover, its non-combustible properties render it a safer alternative. The ease of installation and maintenance further add to its appeal, as do its ability to withstand adverse weather conditions like heavy rain, snow, and wind. Notably, aluminum also earns accolades as an environmentally conscious option, boasting 100% recyclability. In summary, aluminum sheets offer a trustworthy and enduring roofing solution for both residential and commercial edifices.

- Q: Can aluminum sheets be anodized with custom colors?

- Yes, aluminum sheets can be anodized with custom colors. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum, and during this process, dyes can be applied to achieve a wide range of custom colors.

- Q: What is the typical shear strength of aluminum sheets?

- The shear strength of aluminum sheets can vary depending on several factors, including the alloy, temper, thickness, and manufacturing process. Typically, common aluminum alloys have a shear strength ranging from 207 to 310 megapascals (MPa) or 30,000 to 45,000 pounds per square inch (psi). It is crucial to understand that these values serve as general guidelines, and specific applications and conditions may result in variations. When dealing with critical applications, it is advisable to refer to the material specifications or consult professionals to accurately determine the shear strength requirements for the specific aluminum sheet in use.

- Q: Can aluminum sheets be powder-coated?

- Indeed, aluminum sheets undergo powder coating, a procedure involving the electrostatic application of dry, powdered paint onto a surface. Subsequently, the coated aluminum is subjected to heat curing, resulting in a robust and visually appealing finish. Aluminum is particularly well-suited for powder coating due to its lightweight nature and resistance to corrosion. The powder coating firmly attaches to the aluminum surface, creating a protective layer that enhances the sheet's aesthetic appeal while offering enduring safeguard against deterioration.

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of residential buildings?

- <p>Yes, aluminum sheets can be used for exterior walls in residential buildings. They offer several advantages such as durability, resistance to weather and corrosion, and low maintenance. Aluminum is lightweight, which can reduce structural load, and it can be easily shaped and installed. Additionally, it has good thermal performance and can be combined with insulation for energy efficiency. However, it's important to consider the aesthetic appeal, as aluminum may not match the traditional look of some residential buildings, and ensure it meets local building codes and standards.</p>

- Q: Can aluminum sheets be used for battery casings?

- Indeed, battery casings can be made using aluminum sheets. Aluminum, a metal that is both lightweight and durable, possesses superb corrosion resistance, making it an ideal option for battery casings. Moreover, aluminum exhibits excellent electrical conductivity, a crucial factor for optimizing battery efficiency. Furthermore, aluminum can be easily molded and formed into diverse shapes and sizes, granting flexibility in battery casing fabrication. In conclusion, due to its advantageous characteristics, aluminum sheets are widely employed in battery casing production.

- Q: What does aluminum plate "3003-H24" mean?

- 3003 is aluminium manganese alloy aluminum plate (Al--Mn), which is mainly composed of manganese.H24: continuous casting, continuous rolling, Zhang Liqiang and partial toughening.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more). Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.Aluminium alloy is added in the process of aluminum alloy elements (main alloying elements copper, silicon, magnesium, zinc, manganese, minor alloying elements such as nickel, iron, chromium, titanium, lithium, etc.) in order to improve the mechanical properties of aluminum and chemical index. Alloy aluminum sheet has some special properties of pure aluminum plate, and is widely used in special environment, such as ship, refrigerator, mould, aerospace equipment, etc..

- Q: This question asks for a list of various types of fasteners that can be used to secure aluminum windows to their frames.

- <p>There are several types of fasteners used for attaching aluminum windows to frames, including: 1. Screws: Commonly used for their secure hold and ease of installation. 2. Nails: Quick to use but may not provide the same level of security as screws. 3. Adhesives: Can be used for a more permanent bond, especially in certain applications. 4. Clips and brackets: Used for a more visible, decorative attachment. 5. Rivets: Provide a strong, permanent connection but are not easily removable. 6. Dowels and pins: Used for a more traditional or decorative join. 7. Structural glazing systems: Employ silicone or other sealants to bond the window to the frame. Each type of fastener has its own advantages and is chosen based on the specific requirements of the project, such as load-bearing needs, aesthetic considerations, and the desired level of permanence.</p>

- Q: Are aluminum sheets suitable for artistic sculptures?

- Yes, aluminum sheets are suitable for artistic sculptures. Aluminum is a versatile material that can be easily shaped, manipulated, and welded. It is lightweight, durable, and resistant to corrosion, making it ideal for creating intricate and long-lasting sculptures. Additionally, aluminum's natural silver color can add a contemporary and modern aesthetic to the artwork.

Send your message to us

Perforated Aluminum Checkered Sheet AA1100 for Automotive Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords