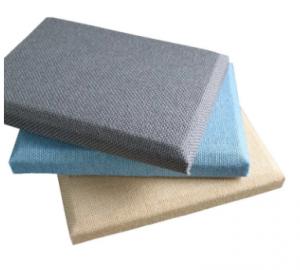

Fiberglass Wall Panel with Low Density

- Loading Port:

- Shanghai, China

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Container m²

- Supply Capability:

- 10 Container/Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Materials: PVC Resin, Calcium Carbonate

Thickness: 5, 6, 7, 7.5, 8mm

Width: 200, 250, 300, 320mm

Length: 5.8m (20GP), 5.95m (40HQ)…

Weight: 2, 2.2, 2.5, 2.8kgs/m2…

PVC content: 40%, 45%, 50%, 55%, 60%...

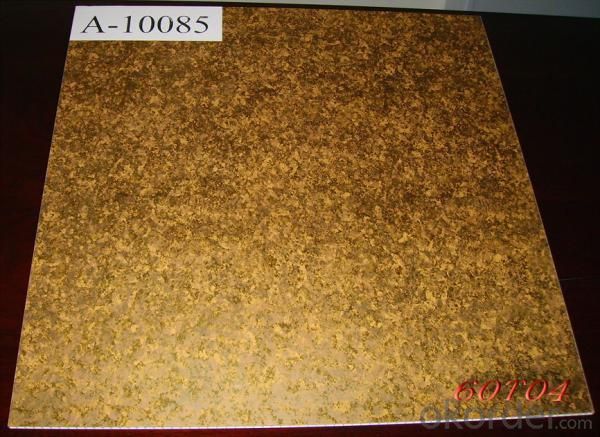

Textures: Printed Series, Glossing Series, Foiled Series, Laminated Series

Processing performace of PVC Panel:

Can be processed by drilling, sawing, nailing, planning and bonding and be in hot-forming, hot-bending and hot-folding and be welded and bonded with supplementary materials.

Main Characteristic of PVC panel:

Water proof and suitable for both wet and dry areas

Interlocking system, DIY supported

Simple and efficient to install and clean

Long life time

Healthy and environmentally friendly

Variety of colors and patterns for decoration

Application Areas of PVC Panel:

The Interior Wall and Ceiling of Bathrooms, Kitchens, Factories, Workshops, Warehouses...

- Q: How to print on the PVC board, there must be a production process Oh, I have a engraving machine, you can carve PVC board, but do not know how to screen printing

- Need to have a screen ink scraping gum and the like I can give you technical support

- Q: I recently used PP board (non-PVC board) to do a turtle pool, but in the paste when found with hot melt adhesive anyway will be leaking, has been repeated several times, but also with the screw

- Joint with glass glue, or with tin foil paste the place where the leakage and then bonding

- Q: What are the advantages and disadvantages of cork flooring? Does anyone know what is Pvc floor?

- 1, wear less compressive pressure If the oppressive object is pressed against the light wall panel, the floor may be pressed out of the pit. Deformation of the object is divided into elastic deformation and plastic deformation, elastic deformation can be restored but the plastic deformation can not, if beyond the range of elastic deformation, it becomes a plastic deformation, it can not be restored. In daily life, it is best to wear soft soles on the cork flooring to prevent the sand into the room, it is recommended to shop at the door shop a rub foot pad, and timely removal of sand into the room to reduce the wear and tear on the floor. 2, clean care is relatively easy With a groove, the cork flooring is a relatively rough appearance of the cork attached to the cork. Visual appearance of the original ecological feeling. But it is such a structure, will be easier to save ash, the need for proper use and maintenance, clean and care more carefully. Ordinary cork flooring waterproof, anti-corrosion performance as hard as the floor, moisture is also easier to penetrate, to prevent ink, lipstick and so get on the floor, otherwise easy to penetrate difficult to clean. PVC flooring is a very popular in the world today, a new type of lightweight ground decoration materials, also known as "light body material." Use a wide range, such as home, hospitals, schools, office buildings, factories, public places, supermarkets, commercial, sports venues and other places. PVC flooring refers to the use of PVC material produced by the floor. Specifically, polyvinyl chloride and its copolymer resin as the main raw material, adding filler, plasticizer, stabilizer, coloring agent and other accessories, in the continuous sheet on the substrate, the coating process or by rolling, extrusion or extrusion Craft production.

- Q: What is a bubble wallboard?

- With foam and other simple materials to build the wall, mostly temporary housing and so on.

- Q: What are the characteristics of PVC, the role?

- Polyvinylchloride (PVC) The name is Polyvinylchlorid, the main ingredient is polyvinyl chloride, bright color, corrosion resistance, durable, due to the increase in the manufacturing process of plasticizers, anti-aging agent and other toxic auxiliary materials to enhance its heat resistance, toughness, extension Sex, etc., so its products generally do not store food and medicine.It is the world's favorite, quite popular and also widely used in a synthetic material. Its global use in a variety of synthetic materials in the second According to statistics, only one year in 1995, PVC production in Europe is about five million tons, while its consumption was 5.3 million tons in Germany, PVC production and consumption of an average of one Four hundred thousand tons.PVC is 4% growth rate in the world to be produced and applied in recent years, PVC growth in Southeast Asia is particularly significant, thanks to the Southeast Asian countries have the urgent need for infrastructure construction In a material that can produce a three - dimensional surface film, PVC is the most suitable material.

- Q: PU wallboard and PVC wallboard, which is better

- Personally feel, PU wallboard to be better. PU wallboard, rough texture, rich colors, natural form, let the family return to nature, highlighting the original nature of the wall, between the classical and fashion to find the soul of the self.

- Q: What are the glass decorations for your home decoration?

- Ecological wood, also known as green wood, green ecological wood, the quality of its raw materials, formula science and ecological wood is the main raw material of PVC resin and high quality wood powder, PVC resin using medical grade domestic brand-name products, wood by the professional wood company to provide quality Tree wood powder, after grading screening, grinding, drying, coating treatment, to ensure that the finished product on the quality requirements of raw materials. The ecological wood door formula system is equipped with a certain proportion of auxiliary materials, into the stabilizer, foaming agent, modifier, etc., various ingredients according to the strict ratio of mixing, effectively guarantee the quality of foam sheet products.

- Q: What are the noncombustible materials?

- Plasterboard, fire retardant plastic decorative board, flame retardant double-sided particleboard, colorful paint, flame retardant plywood, flame retardant plywood, flame retardant plywood, Wallpaper, fire retardant wall cloth, flame retardant imitation granite decorative plate, magnesium chloride cement assembly wall panels, flame retardant glass fiber reinforced plastic plate, PVC plastic wall panels, flame retardant molded wood composite sheet, color flame retardant wood-based panels, difficult Burning glass steel and so on Hard PVC plastic flooring, cement particle board, cement wood board, neoprene flooring and so on

- Q: Pvc wall board toxic?

- With non-flammability, high strength, weather resistance and excellent geometric stability. PVC has a strong resistance to oxidants, reducing agents and strong acids. However, it can be strongly oxidized acid such as concentrated sulfuric acid, concentrated nitric acid corrosion and does not apply with aromatic hydrocarbons, chlorinated hydrocarbons in contact with the occasion. In addition the game term person vs computer, abbreviated as PVC, and PVC humanoid is often referred to as PVC, etc., there is a certain harm.

- Q: Parking, wall, floor and other commonly used decoration materials fire performance (fire rating)?

- Level B2: (1), all kinds of natural wood, wooden wood-based panels, bamboo, paper decorative panels, decorative veneer wood panels, printed wood-based wood panels, plastic veneer decorative panels, polyester decorative panels, Fiberboard, plywood, plastic wallpaper, non-woven wall covering, wall covering, composite wallpaper, natural materials, wallpaper, leather and so on. (2), floor materials: Semi-rigid PVC plastic flooring, PVC coil flooring, wood flooring and other carpet. (3), decorative fabric: Pure wool decorative cloth, pure linen cloth, the other fire-retardant fabric and so on. (4), other decorative materials: Polyethylene, polypropylene, polyurethane, polystyrene, glass fiber reinforced plastic, chemical fiber fabrics, wood products and so on.

1. Manufacturer Overview

| Location | Haining,China |

| Year Established | 1998 |

| Annual Output Value | US$1.5 Million - US$2 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO 9001:2000 certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 18800 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered;Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Fiberglass Wall Panel with Low Density

- Loading Port:

- Shanghai, China

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Container m²

- Supply Capability:

- 10 Container/Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords