Ceramic Filter Plate for Steel Casting Industry

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Foam Filter for Steel Casting Industry

Composite of Ceramic Foam Filter for Steel Casting Industry

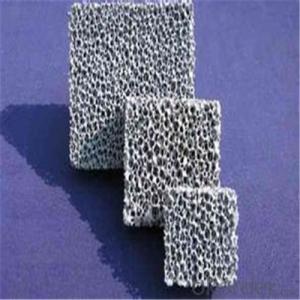

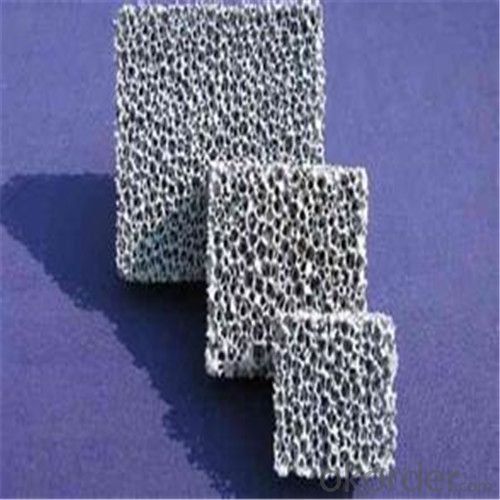

Ceramic Foam Filter is developed as a new type molten metal filters to decrease casting flaw in recent years. Foamed ceramics have the characters of light weight, high mechanical strength, large specific surface areas, high porosity, excellent thermal shock resistance, chemical corrosion resistance and high temperature stability in molten metal. With the distributing pores net structure, they are able to increase the surface areas, and absorb the sinter, the liquid metal becomes more pure, waster quality problems such as sand pore and air pore are much less and the cast quality becomes much better.

Advantages of Ceramic Foam Filter for Steel Casting Industry:

Precise Dimension Tolerance

High Mechanical Strength

Chemical Stability and Corrosion-resistance for molten aluminum.

Phosphate-free, No Pollution for Environment

Purifying Liquid Aluminum, Improving Quality

Reduce Defects

Reduce Cost

Increase Yield Rate

Easy to Use

Size from 40-600mm available.

Ceramic Foam Filter for Steel Casting Industry Images

Specification of Ceramic Foam Filter for Steel Casting Industry:

Item | Unit | Alumina Foam Filter | Sic Foam Filter | Zirconia Foam Filter |

Bore Density | ppi | 10~80 | 10~60 | 10~40 |

Porosity | % | 80~90 | 80~90 | 80~90 |

Max.working Temperature | °C | 1100 | 1550 | 1700 |

Bending Strength | Mpa | 0.6 | 0.7 | 0.8~1.0 |

Compression Strength | Mpa | 0.7 | 0.8 | >1.2 |

Thermal Shock Resistance | times/1100°C | >6times | >6times | >6times |

SiC | % |

| ≥60 |

|

Al2O3 | % | ≥85 | ≤30 |

|

SiO2 | % | ≤15 | ≤10 |

|

ZrO2 | % |

|

| ≥95 |

Others | % |

|

| ≤5 |

application |

| Alumina and Alumina Alloy Non-ferrous | Grey Iron, Ductile Iron | Steel casting |

FAQ of Ceramic Foam Filter for Steel Casting Industry

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

- Q: What filter material are placed in the aquarium filter?

- Submerged in water. Submersible pumps and filter cotton (often replaced by sponge) installed in one, and some brands will also be installed heaters, which become multi-purpose fish farming equipment. When working, the water is absorbed into the filter in many directions, and the filtered water is returned to the water tank by other means. This filter because of its low price and popular beginners of all ages, but the effects from the use of view, only suitable for small fish density, on the flow and filtration requirements are not high, a small aquarium, "fish" will be built in filter (especially the heating function of the filter for seedling and foster) water tank. The effect is very good. The biggest disadvantage of this device is that when it stops working, a lot of dirt stuck to the filter runs back into the water.

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- Ceramic filter plate.The ceramic filter plate does not match the blockage or selection of new plate porosity is generally around 40%, such as ceramic filter plate has hole blocking, the opening rate will become less, when the suction effect into 30% relatively new plate may be slightly worse, when the ceramic filter plate is used for a long time after the opening rate is 10% or less, then the ceramic filter plate suction effect will become very poor even suction. At this time, even if the vacuum suction is good, also do not suck sizing, you need to replace the new ceramic filter board.

- Q: What is the working pressure of the ceramic filter?

- The backwash pressure is the size of the backwash of the ceramic filter during recoil stage, and the recoil pressure is generally less than 0.12MPa. The greater the pressure, the better the recoil effect, the better the service life and the suction effect of the ceramic filter plate, and the worse the service life and the suction effect of the ceramic filter board. The backwash pressure of the ceramic filter shall be no less than 0.07MPa.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large

- The concentration, particle size and mud content of the raw materials are not suitable for or due to changes, which are no longer suitable for dehydration using ceramic filters

- Q: Does the ceramic factory use hydrochloric acid?

- Ceramic filter comes with a combined cleaning system, usually to ensure backwashing normal, combined cleaning (nitric acid + ultrasonic + backwash) in place.

- Q: How can I avoid the backwash pressure in the production of ceramic filter?

- Recoil of the ceramic filter is on the clean water under certain pressure, from the inside out flushing blockage blockage in the ceramic filter plate on the internal pore water pressure, the recoil is generally less than 0.12MPa, the pressure is too small or no recoil recoil effect is not good.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large?

- There is a difference between the vacuum display and the actual vacuumThe main speed of the ceramic filter is too fastThe water content of the filter cake is gradually increased within 0~8 hours after the equipment has been continuously turned onThe ceramic filter plate does not meet the aperture range and the opening rate is lowThe ceramic filter plate has a near life and serious blockageCeramic filter cleaning standards (acid, ultrasonic, backwash water)The scraper can not be completely discharged, and the surface of the ceramic plate is coated with a thin filter cakeFailure to manufacture equipment or other causes of failure

- Q: Excuse me, what's the reason that all ceramic filters do not attract ore?

- Whether the ore conditions are changed, such as pulp type, mud content, fineness, concentration, etc..

- Q: The vacuum of ceramic filter is not enough

- The vacuum degree of ceramic filter is about -0.08MPa, if the ceramic filter is less than 0.06MPa, the vacuum is not enough. If the vacuum of ceramic filter is not enough, it will influence the suction effect of ceramic filter (mainly the thickness of filter cake and water content of filter cake).

- Q: What are the functions of honeycomb ceramic filters?

- At present, it is widely used in metallurgy, foundry industry, metal melt filtration, using mullite (cordierite) ceramic materials

Send your message to us

Ceramic Filter Plate for Steel Casting Industry

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords