Ceramic Filter Plate for Steel Making Industry

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

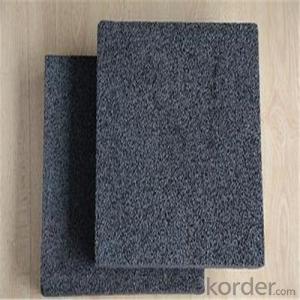

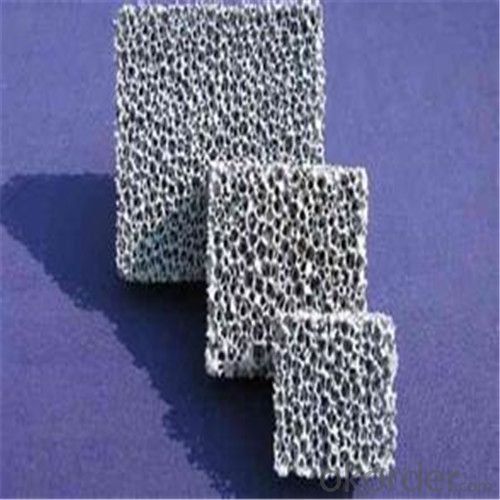

Ceramic Foam Filter for Steel Making Industry

Composite of Ceramic Foam Filter

Ceramic Foam Filter is developed as a new type molten metal filters to decrease casting flaw in recent years. Foamed ceramics have the characters of light weight, high mechanical strength, large specific surface areas, high porosity, excellent thermal shock resistance, chemical corrosion resistance and high temperature stability in molten metal. With the distributing pores net structure, they are able to increase the surface areas, and absorb the sinter, the liquid metal becomes more pure, waster quality problems such as sand pore and air pore are much less and the cast quality becomes much better.

Advantages of Ceramic Foam Filter:

Precise Dimension Tolerance

High Mechanical Strength

Chemical Stability and Corrosion-resistance for molten aluminum.

Phosphate-free, No Pollution for Environment

Purifying Liquid Aluminum, Improving Quality

Reduce Defects

Reduce Cost

Increase Yield Rate

Easy to Use

Size from 40-600mm available.

Ceramic Foam Filter Images

Specification of Ceramic Foam Filter:

Item | Unit | Alumina Foam Filter | Sic Foam Filter | Zirconia Foam Filter |

Bore Density | ppi | 10~80 | 10~60 | 10~40 |

Porosity | % | 80~90 | 80~90 | 80~90 |

Max.working Temperature | °C | 1100 | 1550 | 1700 |

Bending Strength | Mpa | 0.6 | 0.7 | 0.8~1.0 |

Compression Strength | Mpa | 0.7 | 0.8 | >1.2 |

Thermal Shock Resistance | times/1100°C | >6times | >6times | >6times |

SiC | % |

| ≥60 |

|

Al2O3 | % | ≥85 | ≤30 |

|

SiO2 | % | ≤15 | ≤10 |

|

ZrO2 | % |

|

| ≥95 |

Others | % |

|

| ≤5 |

application |

| Alumina and Alumina Alloy Non-ferrous | Grey Iron, Ductile Iron | Steel casting |

FAQ of Ceramic Foam Filter

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q9:Can U accept the detective of the third-party verification company ?

A:YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

If you have any enquiry,please don't hesitate to contact us, we will provide our best products and services for you!!

- Q: Is the filter plate of the ceramic filter afraid of freezing?

- In addition, the temperature is one of the factors affecting the filter suction effect of ceramic filter. The lower the temperature, the worse the suction effect.Therefore, the ceramic filter plate, especially the ceramic filter plate after use, should be protected under low temperature environment.

- Q: What are the materials that make up the ceramic mold?

- At present, the commercialized porous ceramic membranes are mainly composed of 3 types: flat plate, tubular and multi channel. Flat film is mainly used for small-scale industrial production and laboratory research. The tubular membrane is combined with rice to form a heat exchanger similar to a column tube heat exchanger, which can increase the loading capacity of the membrane, but is gradually withdrawn from industrial application due to its strength problem. The size of the applied ceramic membrane usually adopts a multi channel configuration, that is, a plurality of channels are distributed on a circular cross-section, and the number of general channels is 7, 19 and 37. The main business of the inorganic ceramic membrane preparation technology: using solid particle sintering preparation carrier and microfiltration membrane by sol-gel method in the preparation of ultrafiltration membrane: glass membrane by phase separation method: using special technology (such as chemical vapor deposition, electroless plating, etc.) the preparation of microporous membrane or dense membrane. Its basic theory involves colloid and surface chemistry, material chemistry, solid state ion science, material processing and so on.

- Q: Why does not the iron filter of the ceramic filter work?

- The ore condition has changed, such as high concentration of material, fine grain size and increase of mud content.

- Q: The working principle of ceramic filter

- The working principle and mechanism and the shape of ceramic filter disk vacuum filter is similar to that in the pressure under the action of suspension by filtration medium, particles are trapped cake is formed at the surface of the medium, and the liquid through a filter medium outflow, reached the purpose of solid-liquid separation. The difference is that the filter medium of ceramic filter plate with microporous capillary effect, the capillary force in the pores is larger than the vacuum force applied to microporous keep full liquid state, no matter under what circumstances, the ceramic filter plate does not allow air through, because there is no air through solid-liquid separation, low energy consumption, vacuum a high degree of.

- Q: What is the reason that ceramic filter does not absorb mineral powder?

- In order to avoid frequent fluctuations in pressure and pressure within a short period of time, a buffer cylinder with a stabilizing effect is provided in the backwash pipe.

- Q: The vacuum of ceramic filter is not enough

- Maybe the vacuum meter is broken. It doesn't show or show the data is different from the actual data.It could be the source of the vacuum, the vacuum pump failure.Pipeline leakage: vacuum system connecting pipes (metal pipes or rubber pipes) corrosion, aging and water leakage.Distributor head leakage: wear or poor sealing.Leakage of ceramic plate: rupture of ceramic plate.Other reasons.

- Q: What are the reasons for the program alarm of ceramic filter?

- If you say "lean" is the ceramic filter suction when the ceramic filter plate into a cake of thin, high water content, is the ceramic filter for their own reasons, can from the following aspects: the investigation considering this phenomenon is always so recently or just happened, if you have been so, probably because your selection is not suitable for pulp the ceramic filter (such as mud content, fine grain size, ceramic filter plate selection such as inconsistent or unqualified ceramic filter). If this anomaly has occurred recently, it is possible to change the ore condition, and the operation parameters of ceramic filters or the cleaning are not up to standard. You can check the vacuum system (vacuum generally ranges from -0.09 to -0.075MPa), backwashing system (generally refers to the filtered water recoil 0.07 ~ 0.12MPa), acid (HNO3 system standards), ultrasonic system is normal.

- Q: What about the leakage of the ceramic filter static and dynamic sealing points?

- The filtrate pump works to drain or recycle the water that has been pumped out. 6 、 cleaning system work, cleaning system includes backwashing (water pump pressure or height difference pressure), acid liquid (metering pump, automatic acid injection), ultrasonic (ultrasonic work), etc.. 7 、 control system and other electrical systems. In addition, the filter cake which is absorbed and dried on the ceramic filter plate is unloaded automatically by the scraper and then falls on the belt conveyor, and is conveyed to the concentrate storage yard by a belt conveyor. Other questions about ceramic filter, welcome to chat with me or look at my head

- Q: How to determine the quality of ceramic fiber filter board simply?

- Ceramic fiber filter board, in fact, ceramic fiber board, also known as aluminum silicate, refractory fiberboard.

- Q: Can the ceramic plate filter the hot air?

- Ceramic filter by vacuum suction effect in the ceramic filter plate to cake drying purpose, ceramic filter plate needs cleaning and life, if you discover that the slurry sucking effect is poor or even grout should first consider the three aspects: the two factors of ceramic filtering plate of ceramic filter plate most likely, are fracture and hole plugging: rupture will lead to distortion and poor vacuum cleaning; plugging holes will cause the filter plate suction effect is poor even if grout, ceramic filter plugging hole, can strengthen the appropriate cleaning (such as shortening cleaning cycle, prolong the cleaning time, increase the amount of nitric acid, such as strengthening cleaning etc.) after the effect is still not improved, you should consider the life is approaching should be scrapped and replaced with ceramic filter plate new (replacement plate should not put new or different manufacturers is mounted on the same line, the most OK, complete replacement.).

Send your message to us

Ceramic Filter Plate for Steel Making Industry

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords