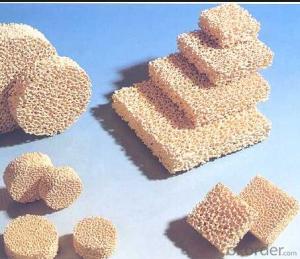

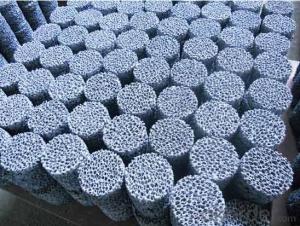

Ceramic Filter Plate for Silicon Carbide Foam Ceramic Filter in Iron or Iron Alloy Casting

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description of ceramic foam filter

Characterized by high porosity,stability and excellent resistance to thermal attack

Compared with traditional filtering materials,the ceramic foam filter has obvious advantages:

2. Functions of ceramic foam filter

1). Thermal and chemical stability in high temperature,avoiding the chemical reaction with the filtered molten metal;

2). High porosity and good mechanical strength in high temperature due to its pure ceramic composite;

3). Low head loss,easy operation,energy-saving;

4). Making metal liquid flowing at stable speed and avoiding the sputtering and backset,thus increasing the surface quality of the cast part,preventing the pore disfigurement and finally lower down the unqualified rate;

5). Various sizes,shapes,apertures are available for kinds of foundry technique.

3.Physical and chemical properties

Main Performance Index:

Item | Carborundum (SiC) |

| pore density PPI | 10-40 |

| porosity (%) | 80-90 |

| refractoriness (°C) | 1500 |

| bending strength (Mpa) | 0.8 |

| compression strength (Mpa) | 1.0 |

| thermal shock resistance (times @ 1100°C) | 6 |

| applying for alloys | Cast Iron |

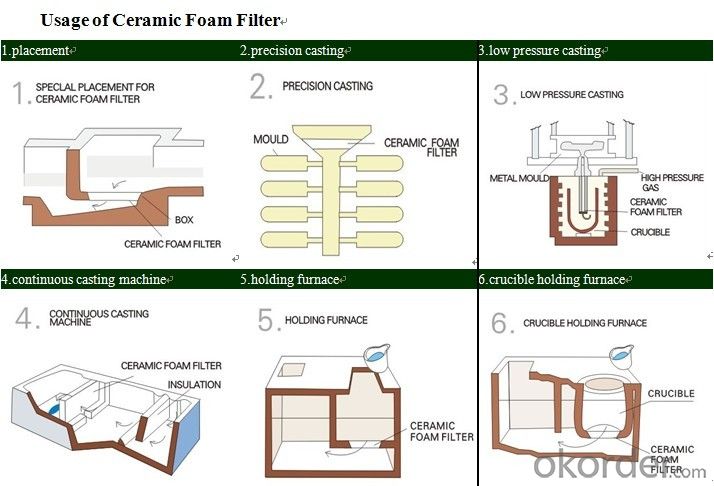

4.Usage of ceramic foam filter

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What filter material are placed in the aquarium filter?

- Submerged in water. Submersible pumps and filter cotton (often replaced by sponge) installed in one, and some brands will also be installed heaters, which become multi-purpose fish farming equipment. When working, the water is absorbed into the filter in many directions, and the filtered water is returned to the water tank by other means. This filter because of its low price and popular beginners of all ages, but the effects from the use of view, only suitable for small fish density, on the flow and filtration requirements are not high, a small aquarium, "fish" will be built in filter (especially the heating function of the filter for seedling and foster) water tank. The effect is very good. The biggest disadvantage of this device is that when it stops working, a lot of dirt stuck to the filter runs back into the water.

- Q: How many degrees does the ceramic filter melt?

- Spinel is basically over 1600-1700. It's not too acid proof.There are other materials such as silicon nitride. Ceramics can be more than 1300 degrees in temperature. So the material you are using now is unlikely to melt and melt, and you can change it into one of the top materials. Baidu, this stuff is all over the street.

- Q: What are the causes of the powder moisture in the ceramic filter?

- The main speed of the ceramic filter is too fast.The vacuum of ceramic filter is not enough.The cleaning of ceramic filter has not met the requirement.The ceramic filter plate has a near life and a serious blockage.The selection of ceramic filter plate is different.Too much residual of ceramic scraper after discharge.

- Q: What are the materials that make up the ceramic mold?

- At present, the commercialized porous ceramic membranes are mainly composed of 3 types: flat plate, tubular and multi channel. Flat film is mainly used for small-scale industrial production and laboratory research. The tubular membrane is combined with rice to form a heat exchanger similar to a column tube heat exchanger, which can increase the loading capacity of the membrane, but is gradually withdrawn from industrial application due to its strength problem. The size of the applied ceramic membrane usually adopts a multi channel configuration, that is, a plurality of channels are distributed on a circular cross-section, and the number of general channels is 7, 19 and 37. The main business of the inorganic ceramic membrane preparation technology: using solid particle sintering preparation carrier and microfiltration membrane by sol-gel method in the preparation of ultrafiltration membrane: glass membrane by phase separation method: using special technology (such as chemical vapor deposition, electroless plating, etc.) the preparation of microporous membrane or dense membrane. Its basic theory involves colloid and surface chemistry, material chemistry, solid state ion science, material processing and so on.

- Q: The efficiency of ceramic filter is low. What's wrong with it?

- Ceramic filter by vacuum suction effect in the ceramic filter plate to cake drying purpose, ceramic filter plate needs cleaning and life, if you discover that the slurry sucking effect is poor or even grout should first consider these three aspects:Ceramic filter plateTwo factors of ceramic filter plate most likely, respectively is the rupture and plugging holes: the rupture will lead to distortion and poor vacuum cleaning; plugging holes will cause the filter plate suction effect is poor even if grout, ceramic filter plugging hole, can strengthen cleaning (such as shorten the cleaning cycle, prolong the cleaning time, increase the amount of nitrate), such as strengthening the cleaning effect is still not improved, it should consider the life approaching should be scrapped and replaced with ceramic filter plate new (replacement plate should not put new or different manufacturers is mounted on the same line, best can complete change).Vacuum system failureThe vacuum degree of ceramic filter is usually about -0.085MPa. If the abnormal vacuum is found, the normal vacuum suction can not be provided, and the suction effect will be poor, or even the pulp will not be sucked.If the vacuum is abnormal, should adhere to the vacuum pump, vacuum connection pipe is whether the fault Water Leakage leakage, distribution valve friction sealing, ceramic filter plate is connected with the rubber tube is aging or exfoliation, ceramic filter plate rupture.

- Q: Principle of chemical engineering drum vacuum filter, the faster the speed, the less the amount of filtrate obtained per turn, the more the amount of filtrate obtained per unit time?

- The faster the speed is, the shorter the time required for each turn, i.e., the shorter the filtration time, the less the filtrate will be

- Q: The working principle of ceramic filter

- Based on the work principle of ceramic filter function of the capillary, by using porous ceramic as filter media, a large number of small capillary action with solid-liquid separation equipment design principle using microporous ceramic disc filter in negative pressure, working conditions, characteristics of the microporous ceramic filter plate with its unique water impermeable, extraction of ceramic filter plate and external vacuum cavity the differential pressure tank suspension material under the action of negative pressure adsorption in the ceramic filter plate, solid material can not through the microporous ceramic filter plate is retained on the surface of the ceramic plate, and the liquid due to the hydrophilic effect of vacuum pressure difference and the ceramic filter plate is passed into the gas-liquid distribution device (vacuum barrel) efflux or recycling so as to achieve the purpose of solid-liquid separation.

- Q: The use of water glass as beneficiation agent, copper concentrate in the ceramic filter can not filter, how to do?

- Water glass is a kind of adhesive of flotation reagent, after use may cause the pulp viscosity increased, leading to the adsorption resistance of slurry becomes large, when using ceramic filter filtration dewatering, vacuum suction surface of the microporous ceramic filter plate is smaller than the resistance, there may be a suction effect or even not suction. Some flocculant agents can lead to this phenomenon.

- Q: Common troubles of ceramic filter

- The metering pump is not working properly and backwash water into the bucket of acid. The main reason is that the metering pump is not switched on, the diaphragm is worn out, the frequency is too low, and the check valve of the acid pipe and backwash pipe is worn out.

- Q: What's the acid of the ceramic filter plate?

- General ceramic filter running for eight hours or so, you need to stop for joint cleaning, general cleaning at an hour or so. When washing together, there is acid washing, usually concentrated nitric acid. The purpose is to dissolve the pores in the ceramic filter plate through nitric acid.

Send your message to us

Ceramic Filter Plate for Silicon Carbide Foam Ceramic Filter in Iron or Iron Alloy Casting

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords