Ceramic Filter Plate - Alumina Ceramic Foam Filter for Foundry Industry 2024

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Alumina Ceramic Foam Filter for Foundry Industry

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: | |

| Material: | PU foam (polyurethane foam) | Size: | Customized | Mesh: | 10 ppi to 60 ppi |

| Property 1: | Mend structure of crystalloid | Property 2: | Reduce foreign matter | Property 3: | Stable chemical property |

| Property 4: | Stable purifying efficiency | polyurethane foam filter: | polyurethane foam |

Packaging & Delivery

| Packaging Details: | carton and pallet, or as customers' requirement |

| Delivery Detail: | 15 days after receiving the downpayment |

Specifications

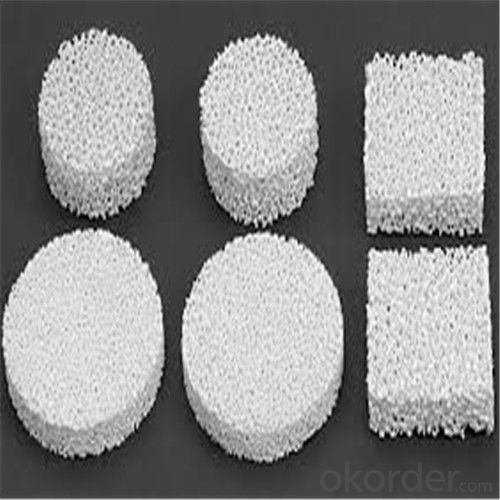

Alumina ceramic foam filter

1.even aperture, high porosity, proper sinter

2.high strength of anti-flexing and anti-compression

Alumina ceramic foam filter

The product, adopted good portiforium foam and high purity ceramic , effectively removes non-metal solid mixture from aluminium and aluminium alloy fusant.

Advantages:

even aperture, high porosity, proper sinter, high strength of anti-flexing and anti-compression, effective filtering.

It is widely applied to the aluminium fusant filter equipment of continuous casting, half-continuous casting, gravity casting, and low pressure casting.

Ceramic foam filters are different from aperture specifications from 10 to 45ppi, with different sizes and shapes.

Besides the general specification ,we can offer the product according to the customers requirements.

Functions of ceramic foam filter

decontaminate the melting metal liquid,Simplified gating system

Improve the metallurgical structure of the castings,Reduce imparities of the castings

Improve casting quality rate,Reduce casting internal re-oxidation defects

Reduce the surface defects after machining of the castings

Physical and chemical properties

Material | Alumina | Silicon Carbide | Zirconia | Magnesia |

Color | White | Grey black | Yellow | Dark yellow |

Pore Density | 8-60ppi | 8-60ppi | 8-60ppi | 8-60ppi |

Porosity | 80-90% | 80-90% | 80-90% | 80-90% |

Refractoriness | ≤1100°C | ≤1500°C | ≤1700°C | ≤1000°C |

Bending Strength | >0.6Mpa | >0.8Mpa | >1.0Mpa | >0.6Mpa |

Compression Strength | >0.8Mpa | >0.9Mpa | >1.2Mpa | >0.8Mpa |

Volume-weight | 0.3-0.45g/cm3 | 0.35-0.5 g/cm3 | 0.9-1.5 g/cm3 | 0.35-0.5 g/cm3 |

Thermal shock resistance | 6times/1100°C | 6times/1100°C | 6times/1100°C | 6times/1100°C |

Application | Aluminium , Aluminium alloys and other Non-ferrous alloys | Ductile Cast Iron, Malleable Cast Iron,Gray iron and other Cast Iron | High melting point metal alloys likeSteel,AlloySteel,Stainless Steel etc | Magnesium and High-Active Alloy |

Specifications for Alumina Casting

Dimensions (mm) | Dimensions (inch) | Pouring Rate (kg/s) | Filtration Capacity (ton) |

178×178×50 | 7×7×2 | 0.2-0.6 | 5 |

228×228×50 | 9×9×2 | 0.3-1.0 | 10 |

305×305×50 | 12×12×2 | 0.8-2.5 | 15 |

381×381×50 | 15×15×2 | 2.2-4.5 | 25 |

430×430×50 | 17×17×2 | 3.0-5.5 | 35 |

508×508×50 | 20×20×2 | 4.0-6.5 | 45 |

585×585×50 | 23×23×2 | 5.0-8.6 | 60 |

Specification for Iron casting

Dimension (mm) | Pouring Rate (kg/s) | Filtration Capacity (kg) | ||

Grey Iron | Ductile Iron | Grey Iron | Ductile Iron | |

40×40×22 | 4 | 3 | 65 | 32 |

50×50×22 | 6 | 4 | 100 | 52 |

75×50×22 | 9 | 6 | 150 | 75 |

75×75×22 | 14 | 9 | 220 | 100 |

100×50×22 | 12 | 8 | 200 | 100 |

100×75×22 | 18 | 12 | 300 | 150 |

100×100×22 | 25 | 16 | 400 | 200 |

150×150×22 | 50 | 36 | 900 | 450 |

Specification for Steel/Magnesium casting

Dimensi | Zirconia Foam Filter | Dimensions (mm) | Magnesia Foam Filter | ||

Pouring Rate(kg) | Filtration Capacity(kg) | Pouring Rate(kg) | Filtration Capacity(kg) | ||

50×50×22 | 3~5 | 30 | 50 D×22 | 4.0 | 60 |

50×75×22 | 4~6 | 40 | 60 D×22 | 7.0 | 80 |

75×75×22 | 7~12 | 60 | 90 D×22 | 10.0 | 120 |

75×100×22 | 8~15 | 80 | 120 D×22 | 16.0 | 160 |

100×100×22 | 14~20 | 100 | 100×100×22 | 13.0 | 140 |

50 D×22 | 2~6 | 18 | 150×150×25 | 22.0 | 260 |

80 D×22 | 6~10 | 50 | 230×230×30 | 130.0 | 3100 |

90 D×22 | 8~16 | 70 | 300×300×40 | 260.0 | 5200 |

Others:

We can supply ceramic foam filters are as follows:

Alumina foam ceramic filter : for molten metal filtering under temperature of 1200 degree.

Silicon Carbide foam ceramic filter: for molten metal filtering under temperature of 1500 degree.

Zirconia foam ceramic filter: for molten metal filtering under temperature of 1700 degree.

Magnesia foam ceramic filter: for molten metal filtering under temperature of 1100 degree.

Welcome to visit our factory~

- Q: The ceramic filter suddenly did not smoke, and later he was all right. What's the reason?

- How old the general ceramic filter suction main reason mud cake thickness is not much of a ceramic filter plate is different, because the ceramic filter backwash water, vacuum suction and nitrate are through the distribution valve, are often the same boat". See your description, you do not know the 5 line is about "5 disc or sideways 5 rows of ceramic plates, that is completely not suction or suction effect is poor, I hope to help you:

- Q: Influence factors of ceramic filter

- Ceramic filter board, also known as ceramic filter membrane, ceramic plate, ceramic plate, filter plate, etc., is made of corundum, silicon carbide and other special process made of new filter media. At present, as the core component of the ceramic filter, ceramic filter plate has been widely used in solid-liquid separation of iron concentrate, zinc concentrate, sulfur concentrate, copper concentrate, nickel concentrate, molybdenum concentrate, lead concentrate, tungsten concentrate, manganese ore, vanadium ore, aluminum ore, gold ore, non-metallic mine Ore Concentrate Dewatering and coal, chemical industry, papermaking, pharmaceutical, chemical, food, environmental protection and other industries.

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- Generally, the vacuum degree of ceramic filter is about -0.08MPa. Sufficient vacuum pressure is only a prerequisite for a good ceramic suction effect. Besides vacuum, the other factors may affect the suction effect:Vacuum display table fault, the difference between the display value and the actual data is great.

- Q: The efficiency of ceramic filter is low. What's wrong with it?

- Ceramic filter by vacuum suction effect in the ceramic filter plate to cake drying purpose, ceramic filter plate needs cleaning and life, if you discover that the slurry sucking effect is poor or even grout should first consider these three aspects:Ceramic filter plateTwo factors of ceramic filter plate most likely, respectively is the rupture and plugging holes: the rupture will lead to distortion and poor vacuum cleaning; plugging holes will cause the filter plate suction effect is poor even if grout, ceramic filter plugging hole, can strengthen cleaning (such as shorten the cleaning cycle, prolong the cleaning time, increase the amount of nitrate), such as strengthening the cleaning effect is still not improved, it should consider the life approaching should be scrapped and replaced with ceramic filter plate new (replacement plate should not put new or different manufacturers is mounted on the same line, best can complete change).Vacuum system failureThe vacuum degree of ceramic filter is usually about -0.085MPa. If the abnormal vacuum is found, the normal vacuum suction can not be provided, and the suction effect will be poor, or even the pulp will not be sucked.If the vacuum is abnormal, should adhere to the vacuum pump, vacuum connection pipe is whether the fault Water Leakage leakage, distribution valve friction sealing, ceramic filter plate is connected with the rubber tube is aging or exfoliation, ceramic filter plate rupture.

- Q: Can the plate filter press pass through the filter plate?

- There are many types of pumps to be used, such as screw pumps, slag pumps, rotary pumps, piston pumps, and diaphragm pumps.

- Q: The use of water glass as beneficiation agent, copper concentrate in the ceramic filter can not filter, how to do?

- As everyone knows, ceramic filter medium is a ceramic filter plate, microporous ceramic filter plate with a lot of distribution from the outside to the inside capillary effect, its mechanism is based on the capillary effect of microporous ceramic filter, filtration, the filtrate (generally refers to water) through these pores under the action of the vacuum suction pump, filter cake is trapped on the surface of the ceramic filter plate.

- Q: What is the working pressure of the ceramic filter?

- Generally speaking, there are two kinds of working pressure of ceramic filter: vacuum pressure and reverse flushing pressure.

- Q: How much is the accuracy of 50nm ceramic membrane filtration?

- It should be noted that due to wear, plugging and so on, the new and different degrees of ceramic film, the pore size will change. Micron scale ceramic membrane filtration accuracy is very good, nano scale aperture range of such a small ceramic film does not know in what way.

- Q: What is the backwashing pressure of the ceramic filter?

- Ceramic filter is a kind of solid-liquid separation, dehydration drying equipment, such as dehydration pulp, mortar. The backwash of ceramic filter is to flush the filter medium (ceramic filter plate) with clean water with a certain pressure.

- Q: Can the ceramic plate filter the hot air?

- The vacuum degree of the ceramic filter in the vacuum system is about -0.085MPa. If the abnormal vacuum is found, the normal vacuum suction will not be available, and the suction effect will be poor, even without suction. If the vacuum is abnormal, should adhere to the vacuum pump, vacuum connection pipe is whether the fault Water Leakage leakage, distribution valve friction sealing, ceramic filter plate is connected with the rubber tube is aging or exfoliation, ceramic filter plate rupture.

Send your message to us

Ceramic Filter Plate - Alumina Ceramic Foam Filter for Foundry Industry 2024

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords