Alumina Ceramic Foam Filter for Carbon Steel Casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

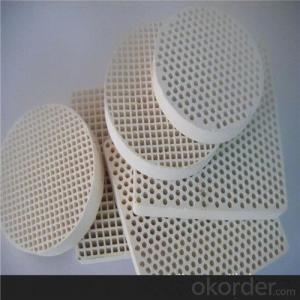

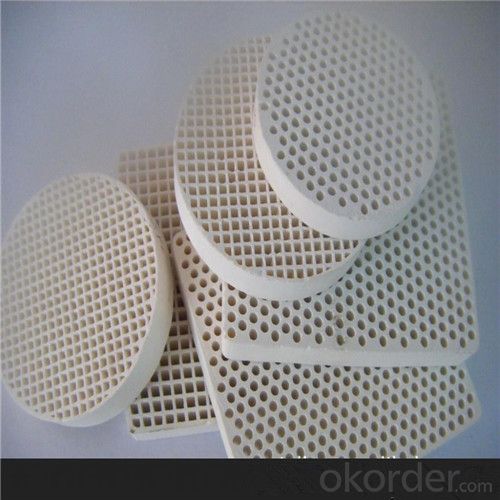

General Information of Ceramic Foam Filters

Alumina ceramic foam filters are widely used in filtering the alumina and alloys in foundries. With 80-90% porosity, the filters can effectively remove the alumina dross to improve the casting quality.

Image of Ceramic Foam Filters

FAQ

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: What are the production methods of calcium silicate board material?

- Calcium silicate (microporous calcium silicate) material and calcium silicate board are produced by static steaming method, dynamic hydrothermal synthesis method and two reaction method.

- Q: What is the maximum temperature at which the glass is cured?

- The softening point of quartz glass is 1600 degrees, it is sodium phosphate and phosphate. Gas burner 1300 degrees, after homogenization processing, after annealing treatment of glass products.

- Q: Calcium silicate board for house ceiling, 6mm or 8mm?

- The calcium silicate board will not have the above shortcomings, the thickness of 15mm if it is the calcium silicate board 4mm ceiling 600*600 thickness can reach the effect of the biggest advantages of mineral wool board, calcium silicate board also is not a burning fire, moisture absorption is very good, green building materials.

- Q: What are the three major effects of fly ash in concrete?

- The "form effect" of fly ash contains many glass beads, the surface is smooth and the texture is dense. It is this form to water reducing effect, compact and homogeneous effect, can promote the early hydration of cement flocculation effect of solution, change the mixture rheological properties, the initial structure and hardening of the various functions, especially for pumping concrete, can play a good role in lubrication.

- Q: Eterpan and yinte in what is the difference?

- The silver plate refers to the calcium silicate board. Silver is a trademark, and calcium silicate board is the name of the product

- Q: What are the main use of lime?

- A rigid inorganic cementitious material consisting mainly of calcium oxide. Lime is made from limestone, dolomite, chalk and shell with high content of calcium carbonate and calcined at 900~1100 DEG C. Lime is one of the earliest cementitious materials used in human life. Lime is widely used in civil engineering and can be used in medicine in our country.

- Q: What's the use of low carbon steel insulated nail hooks for power plants?

- Low carbon steel nail insulation (aka: insulation pins) material: low carbon steel wire for power plants or stainless steel wire products: insulation nail. Hook nail is a power plant by mechanical processing of special insulation nail models: nail diameter: 3 mm with 3.5mm with 4 mm with 5 mm with 6 mm etc.

- Q: What is the main role of fly ash added in concrete products?

- The workability of fresh concrete can be improved by adding fly ashThe workability of fresh concrete is affected by the volume, water cement ratio, gradation, shape and porosity of the aggregate. The fly ash is used for fresh concrete is the obvious benefits of increasing the slurry volume, slurry filled with aggregate between pores, inclusions and lubrication of aggregate particles, so that the concrete mixture has better cohesiveness and plasticity. The aggregate particles of fly ash can reduce the interfacial friction between the paste and aggregate, and improve the workability of the concrete mixture at the contact point of the aggregate.

- Q: How to make building glue?

- The invention relates to an architectural adhesive, which is characterized in that the composition of the building glue comprises 28-50wt% sodium silicate water solution, 34-53wt% quartz sand and 8-35wt% magnesium silicate.Adhesive for a building, it is the following: the weight ratio of 4 to 6, PVA cellulose 6 - 12, 1 - 2, copolymer admixture from 0.01 to 0.05, according to the proportion of polyvinyl alcohol with hot water first fully dissolved, then adding cellulose, copolymer, admixture and stir evenly. The glue can be combined with Portland cement or construction gypsum to cement all kinds of light plates. This product is non-toxic and tasteless, harmless to the human body, is a wide range of uses, superior technical performance of environmentally friendly building adhesive.

- Q: What are the exterior walls of the building besides the benzene board and the extruded board?

- Foam heat insulation material mainly includes two categories, polymer foam type insulation material and foam asbestos insulation material. Polymer foam thermal insulation material has the advantages of small absorption rate, stable heat preservation effect, low thermal conductivity, no dust flying in construction, easy construction, etc., and it is in the period of popularization and application.

Send your message to us

Alumina Ceramic Foam Filter for Carbon Steel Casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords