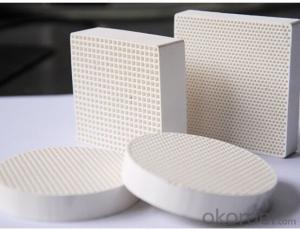

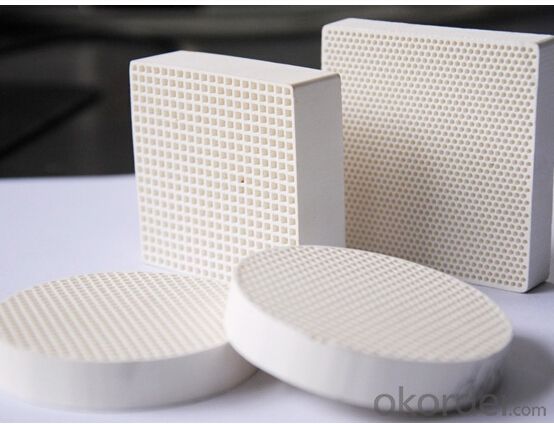

Ceramic Filter Plate - Ceramic Foam for Filtration

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon Carbide Ceramic Foam Filter

Silicon Carbide Ceramic Foam filter is justdeveloped as a new type molten metal filter to decrease casting flaw in recentyears. With its characteristics of light-weight, high mechanical strength,large specific surface areas, high porosity, excellent thermal shock resistance,erode resistance, high-performance, siliconcarbide ceramic foam filter is designedfor filtering impurities from molten Iron & Alloy, nodular cast ironcastings, grey iron castings and malleable castings, etc.

CNBM silicon carbide ceramic foamfilter ischaracterized by high porosity and mechanochemical stability and excellentresistance to thermal shock and corrosion from moltenmetal. It can effectively remove inclusions, reducetrapped gas and provide laminar flow when iron molten metalfiltrated, ceramic foam filter is machined to tight dimensionaltolerance during production, this combination of physical properties andprecise tolerance make them first choice for iron molten metal filtration.

TechnicalData of Silicon carbide ceramicfoam filter

BoreDensity(PPi) 10-40

Porosity(%) 80-90

Highestworking temperature (°C) 1500

BendingStrength (Mpa) 0.8

CompressionStrength(Mpa) 0.9

Thermal ShockResistance (times/1100°C) 6

DirectionsFor Use silicon carbide ceramic foamfilter

a) Dimensions Available:

Square shape:30-600mm

Round shape:φ40-φ300mm

Thicknessesfrom 10-50mm.

PPI:10P,15P,20P,25P,30P,40P

Ductile ironcastings use 10PPI, grey iron castings and tenacity iron casting use10PPPI,15PPI or 20PPI.

b)Filterable Melt Metal Weight Of Grey And Ductile Iron (10PPI):

Dimension | Ductile Iron (≤ kg) | Grey Iron (≤ kg) | metal volume of pouring (kg/sec.) | |

Ductile Iron | Grey Iron | |||

40×40×22 | 30 | 65 | 3 | 4 |

50×50×22 | 55 | 100 | 4 | 6 |

75×50×22 | 75 | 150 | 6 | 9 |

75×75×22 | 100 | 220 | 9 | 14 |

100×50×22 | 100 | 200 | 8 | 12 |

100×100×22 | 210 | 420 | 16 | 25 |

150×150×22 | 450 | 900 | 36 | 50 |

Weclome your enquiry about silicon carbide ceramic foam filter at any time. We are willing to supplyyou superior filters in most competitive price with professional service.

- Q: What filter material are placed in the aquarium filter?

- Submerged in water. Submersible pumps and filter cotton (often replaced by sponge) installed in one, and some brands will also be installed heaters, which become multi-purpose fish farming equipment. When working, the water is absorbed into the filter in many directions, and the filtered water is returned to the water tank by other means. This filter because of its low price and popular beginners of all ages, but the effects from the use of view, only suitable for small fish density, on the flow and filtration requirements are not high, a small aquarium, "fish" will be built in filter (especially the heating function of the filter for seedling and foster) water tank. The effect is very good. The biggest disadvantage of this device is that when it stops working, a lot of dirt stuck to the filter runs back into the water.

- Q: The ceramic filter suddenly did not smoke, and later he was all right. What's the reason?

- How old the general ceramic filter suction main reason mud cake thickness is not much of a ceramic filter plate is different, because the ceramic filter backwash water, vacuum suction and nitrate are through the distribution valve, are often the same boat". See your description, you do not know the 5 line is about "5 disc or sideways 5 rows of ceramic plates, that is completely not suction or suction effect is poor, I hope to help you:

- Q: What are the materials that make up the ceramic mold?

- Ceramic membrane, also known as CT film, is one of the solid membrane, the earliest by Japan's large Japanese printing company and Toyo ink company in 1996, the introduction of the market. The ceramic coating is mainly A12O3, Zr02, Ti02 and Si02 of inorganic materials such as porous membrane preparation, the pore size of 250mm. Has good chemical stability, acid resistance, alkali resistance, solvent resistance, high mechanical strength, can reverse flushing: anti microbial ability: high temperature, narrow pore size distribution, higher separation efficiency characteristics, has been widely used in food industry, biological engineering, environmental engineering, chemical industry, petroleum chemical industry, metallurgy industry etc. The market sales, with an annual growth rate of 35% growth. Compared with plastic products of ceramic membrane with similar high cost, but also has many advantages, it is hard to withstand strong, durable, not easy to have chemical resistance village, invasive and high temperature liquid cleaning liquid has a stronger ability to resist, its main drawback is the price expensive. _ complex manufacturing process

- Q: How much is the accuracy of 50nm ceramic membrane filtration?

- It should be noted that due to wear, plugging and so on, the new and different degrees of ceramic film, the pore size will change. Micron scale ceramic membrane filtration accuracy is very good, nano scale aperture range of such a small ceramic film does not know in what way.

- Q: Does the ceramic factory use hydrochloric acid?

- In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q: Ceramic filter ceramic plate blockage, productivity reduction, how to clean, to achieve the best effect cleaning problems

- Selection of new ceramic filter plate:Because of the different size and characteristics of the pulp, different users need ceramic filter plates with different pore sizes (i.e., the average range of their surface pore size). In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q: How can I avoid the backwash pressure in the production of ceramic filter?

- The backwashing system of ceramic filter is usually made up of water inlet, water inlet, pressure gauge, water filter and filtered water pressure gauge, and then connected to the inside of ceramic filter. Such as the discovery of ceramic filter recoil pressure became smaller or even no recoil pressure, you can carefully observe the surface of the ceramic filter plate is wet or ceramic filter plate wear without water injection at the discharge point, investigation and the reasons for the following aspects:Is the water inlet pressure or normal?How about the sealing performance of the water filter? Does the filter element need to be replaced?Is the recoil system piping (metal pipe, ceramic filter plate, connecting pipe, etc.) broken, leaking or dripping?Is the distributor valve properly installed and is it worn?Are there any cracks in the ceramic filter plate?Is the pressure gauge broken?The most likely reason is 1, 2, two, the best water should not be too dirty, filter should be replaced regularly. I hope the answer can help you.

- Q: The vacuum of ceramic filter is not enough

- Maybe the vacuum meter is broken. It doesn't show or show the data is different from the actual data.It could be the source of the vacuum, the vacuum pump failure.Pipeline leakage: vacuum system connecting pipes (metal pipes or rubber pipes) corrosion, aging and water leakage.Distributor head leakage: wear or poor sealing.Leakage of ceramic plate: rupture of ceramic plate.Other reasons.

- Q: Ceramic filter suddenly do not smoke, a little later on their own good, what reason?

- How old the general ceramic filter suction main reason mud cake thickness is not much of a ceramic filter plate is different, because the ceramic filter backwash water, vacuum suction and nitrate are through the distribution valve, are often the same boat". See your description, you do not know the 5 line is about "5 disc or sideways 5 rows of ceramic plates, that is completely not suction or suction effect

- Q: What about the leakage of the ceramic filter static and dynamic sealing points?

- When the ceramic filter works, the operation may be as follows: 1. The feed is injected and the pulp is injected into the tank of the ceramic filter. 2, mixing system, ceramic filter stirring rake back and forth mixing, driven by mixing reducer. 3, spindle rotation, material level reached a certain range, through the spindle speed machine to drive the ceramic filter disk rotation.

Send your message to us

Ceramic Filter Plate - Ceramic Foam for Filtration

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords