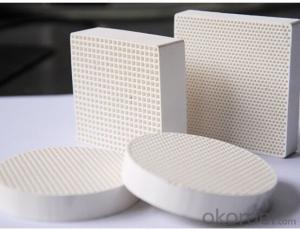

Ceramic Filter Plate - Ceramic Foam Filter with Good Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon Carbide Ceramic Foam Filter

Silicon Carbide Ceramic Foam filter is justdeveloped as a new type molten metal filter to decrease casting flaw in recentyears. With its characteristics of light-weight, high mechanical strength,large specific surface areas, high porosity, excellent thermal shock resistance,erode resistance, high-performance, siliconcarbide ceramic foam filter is designedfor filtering impurities from molten Iron & Alloy, nodular cast ironcastings, grey iron castings and malleable castings, etc.

CNBM silicon carbide ceramic foamfilter ischaracterized by high porosity and mechanochemical stability and excellentresistance to thermal shock and corrosion from moltenmetal. It can effectively remove inclusions, reducetrapped gas and provide laminar flow when iron molten metalfiltrated, ceramic foam filter is machined to tight dimensionaltolerance during production, this combination of physical properties andprecise tolerance make them first choice for iron molten metal filtration.

TechnicalData of Silicon carbide ceramicfoam filter

BoreDensity(PPi) 10-40

Porosity(%) 80-90

Highestworking temperature (°C) 1500

BendingStrength (Mpa) 0.8

CompressionStrength(Mpa) 0.9

Thermal ShockResistance (times/1100°C) 6

DirectionsFor Use silicon carbide ceramic foamfilter

a) Dimensions Available:

Square shape:30-600mm

Round shape:φ40-φ300mm

Thicknessesfrom 10-50mm.

PPI:10P,15P,20P,25P,30P,40P

Ductile ironcastings use 10PPI, grey iron castings and tenacity iron casting use10PPPI,15PPI or 20PPI.

b)Filterable Melt Metal Weight Of Grey And Ductile Iron (10PPI):

Dimension | Ductile Iron (≤ kg) | Grey Iron (≤ kg) | metal volume of pouring (kg/sec.) | |

Ductile Iron | Grey Iron | |||

40×40×22 | 30 | 65 | 3 | 4 |

50×50×22 | 55 | 100 | 4 | 6 |

75×50×22 | 75 | 150 | 6 | 9 |

75×75×22 | 100 | 220 | 9 | 14 |

100×50×22 | 100 | 200 | 8 | 12 |

100×100×22 | 210 | 420 | 16 | 25 |

150×150×22 | 450 | 900 | 36 | 50 |

Weclome your enquiry about silicon carbide ceramic foam filter at any time. We are willing to supplyyou superior filters in most competitive price with professional service.

- Q: The ceramic filter plate is broken. What will happen to the vacuum pump?

- If it is found that the ceramic plate is broken, it should stop in time to replace the broken ceramic plate. Ceramic filter is produced by vacuum suction vacuum pump to the pulp in the water through the ceramic plate away, the surface aperture ceramic plate for several microns, so it can intercept the cake on the ceramic plate on the surface, if the ceramic plate is broken, a hole is a few millimeters, when the vacuum suction pump when they go together along with the pulp pump.

- Q: Is the filter plate of the ceramic filter afraid of freezing?

- In addition, the temperature is one of the factors affecting the filter suction effect of ceramic filter. The lower the temperature, the worse the suction effect.Therefore, the ceramic filter plate, especially the ceramic filter plate after use, should be protected under low temperature environment.

- Q: How many degrees does the ceramic filter melt?

- Spinel is basically over 1600-1700. It's not too acid proof.There are other materials such as silicon nitride. Ceramics can be more than 1300 degrees in temperature. So the material you are using now is unlikely to melt and melt, and you can change it into one of the top materials. Baidu, this stuff is all over the street.

- Q: Influence factors of ceramic filter

- On the other hand, as the spindle speed slows down, the thickness of the slurry is thickened, and the moisture of the concentrate is also affected. For viscous material, ceramic filter with ceramic plate to work as filter media, when the cake is formed gradually into the porous filter medium filter cake itself, and the cake is not easy to form a viscous material, forming a dry cake appearance does not slow, the spindle speed is easy to reduce the water content of concentrate. Similarly, the spindle speed is accelerated, the cake formation time in the vacuum zone is shortened, and the slurry thickness is reduced, and the material can be improved for the easy molding material. But the spindle speed is too fast to be cleaned after each cycle of the ceramic plate. As for the viscous material, the cake is difficult to form after the spindle speed increases, and it will affect the capacity. Therefore, the use of ceramic filter should focus on the inherent nature of the concentrate to explore the best spindle speed. Generally, the higher the temperature, the smaller the viscosity of the liquid, the more conducive to improve the filtration rate, reduce the cake or sediment water, while reducing the viscosity of the slurry, can improve the processing capacity.

- Q: What are the causes of the powder moisture in the ceramic filter?

- Generally, the ceramic filter is used to filter iron powder, and the water content of the filter cake is about 10%.

- Q: Why does not the iron filter of the ceramic filter work?

- The main speed of the ceramic filter is too fast.The vacuum of ceramic filter is not enough.The cleaning of ceramic filter has not met the requirement.The ceramic filter plate has a near life and a serious blockage.The selection of ceramic filter plate is different.Too much residual of ceramic scraper after discharge.

- Q: How much is the accuracy of 50nm ceramic membrane filtration?

- It should be noted that due to wear, plugging and so on, the new and different degrees of ceramic film, the pore size will change. Micron scale ceramic membrane filtration accuracy is very good, nano scale aperture range of such a small ceramic film does not know in what way.

- Q: What is the reason that the ceramic filter does not absorb mineral powder?

- There may be a fault filtrate pump, diaphragm pump damage, pump mechanical seal failure, a leak, two is no output or output to the liquid, the pressure is too low, the cleaning effect is not good, the pressure is too large, will cause damage and reduce the concentration of slurry filter plate.

- Q: Does the ceramic factory use hydrochloric acid?

- For the use of a long time, the method 1, the effect is still no significant improvement, that is how to plug the ceramic filter plate regeneration? The ceramic filter plate with uneven or non sucking slurry can be removed, and oxalic acid or other acid liquid with certain concentration and certain temperature can be taken together to dredge the microporous of the ceramic filter plate. (do not recommend sulphuric acid)

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large?

- There is a difference between the vacuum display and the actual vacuumThe main speed of the ceramic filter is too fastThe water content of the filter cake is gradually increased within 0~8 hours after the equipment has been continuously turned onThe ceramic filter plate does not meet the aperture range and the opening rate is lowThe ceramic filter plate has a near life and serious blockageCeramic filter cleaning standards (acid, ultrasonic, backwash water)The scraper can not be completely discharged, and the surface of the ceramic plate is coated with a thin filter cakeFailure to manufacture equipment or other causes of failure

Send your message to us

Ceramic Filter Plate - Ceramic Foam Filter with Good Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords