Cement Tile with Super High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meters m²

- Supply Capability:

- 5,000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vietnam Handmade Cement Tile

Water Absorption: <= 7%

Abrasion: 0.45gr/Cm2

Weight: 1200gr /- 50gr

Elasticity: 1.200N min

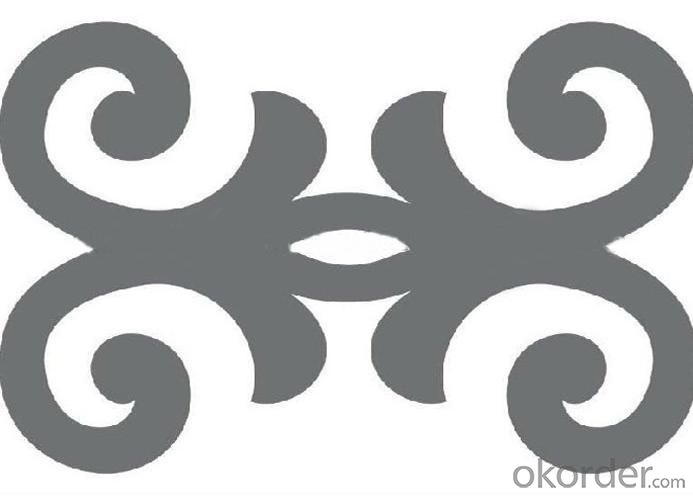

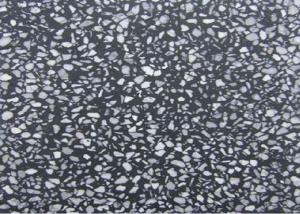

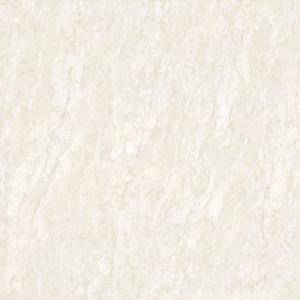

This is encaustic cement tile, a produce of HANDMADE process created by Skillful Artisant from Vietnam, a country has 100s of Year in making encaustic cement tiles, this production in Vietnam is among the best quality in the world. Inheritating long tradition of making encaustic cement tile together with bring new modern technique to production, our Cement tiles have been produced and controlled under the best conditions to guarantee stable quality for all production batches. Basic material are marble powder and pigment, environmental friendly.

All patterns and Colors can be customized

Available sizes from 50x50mm to 400x400mm which thickness ranging from 12mm till 25mm

Technical Specifications and Technological Parameters

Specs:

Length 200mm /-0.5mm

Width 200mm /-0.5mm

Height 15mm /-1.0mm

Top Layer 3mm /-0.1mm

Technological Parameters:

Weight 1200 gr /- 50gr

Elasticity 1.200 Newton minimum

Shock resistance 30 times minimum

Water Absorption <= 7%

Abrasion 0.45 gr/Cm2

This is ideal material from indoor using or interior which is suitable for restoration of old building or for luxurious building such as hotels, restaurants, cafe or even for boutique or cottage house.

Our capacity: 5,000m2 per month equally to 8 containers 20ft per month.

- Q: I'm putting on new arborite on a kitchen counter and can't seem to get get rid of the old contac glue

- Use lacquer thinner. It removes the contact cement, and then it evaporates leaving no residue behind. I'm a carpenter, and we use it all the time when we have to relaminate a countertop. Hope this helps.

- Q: In general which of these three cements creates rocks that are the most resistant to weathering?

- Iron oxide cement will colour the rock a distinctive rusty yellow-brown as a result of the significant presence of the minerals haematite and limonite. Calcite cement will leave the rock white but is soft, easily scratched by an iron nail and will fizz with the application of dilute hydrochloric acid. Silica cement will leave the rock glassy colourless, glassy white or rarely, a different colour but also glassy, it will resist being scratched by an iron nail, and will not react with dilute hydrochloric acid. The rock with the silica cement will be most resistant to weathering, and will normally remain as a positive relief feature around the surrounding rocks. The cement in the calcite cemented rock will tend to become dissolved away. The iron oxide cemented rock will be fairly soft but will resist erosion better than the rock with the calcite cement.

- Q: 1) with river sand2) with lime3) with fly ash please give the reason too.

- cement or concrete. Cement is baked lime. Concrete is a mixture of sand gravel and cement. Fly ash is more of a lubricant and helps to give you a smoother finish. A basic mixture for concrete is 1 cement 2 gravel and 3 sand. To increase the basic strength add more cement as cement is the binder. To much cement and the result will be crumbly. The more sharp points in the type of sand or the more surface texture of the rock increases strength. reinforcement wire or bar will increase structure strength. Dan

- Q: one that holds the best but not messy to work with

- i have heard of Black Jack before and because someone else has adviced it, it must be good. Perhaps ask your local DIY store just incase.

- Q: Are plastic cement and rubber cement the same thing, or are they different? I want to know 'cause I am building a model rocket and it says to use plastic cement, but I don't have any. Or would just plain white glue work?

- no they are completely different. Rubber cement is used mostly to glue flexible materials like rubber / leather and things like that. Plastic cement is clear and hardens completely. It works by melting the plastic chemically and hardening. If you rocket is plastic, use plastic cement. It is available at hobby stores.. walmart ./ target etc. super instant glue might also work.. but the bond is not as strong. plain white glue might work if you are gluing paper/wood..but not so good for plastic. have fun

- Q: Producing cement at a site uses.........A -- energy resources only B -- energy resources and renewable materialsC -- energy resources and non renewable materials D ---- renewable materials onlyQuick answers would be greatly appreciated!!!!!!!

- I would have to say C but B is also attractive. I could make the case that the rock that is used for cement is the result of hundreds of thousands of years in geologic processes. The energy spent to produce the cement is used. However, I could say that cement is very reusable. Old cement can be ground up and reused quite readily. sorry but the question is quite open ended. That is unless your teacher specified an answer in class and you just didn't catch it!

- Q: I'm a student, now studying about derivatives. In type of commodity options, why do we have wheat options, oil options, gold options... why don't we have cement options?And please let me know, is there any qualification, any criteria for choosing a goods to be an underlying asset of a derivative?

- Don't be intimidated by the charts, actually they are not that hard to read and understand. Strategies that are based on reading and analyzing charts are part of the technical analysis area.

- Q: Hey guys, I'm getting a pallet expander tomorrow. I was talking to my friends who have had one in the past and they said they were able to take theirs out. Unfortunately i can not. I was just wondering why could they take theirs out and i cant? The ortho said that mine will be cemented. I only have just a little cross bit with one tooth out of line. Can anyone tell me? Thanks a lot :)

- Both types expand the palate. The difference is that remove able ones are used to obtain a smaller amount of expansion than a cemented one. The one that is cemented can engage the teeth in a more rigid manner and can be more effective in obtaining extra width. The cemented ones usually work quicker and compliance is not a problem. Compliance relates to the tendency for people who have removable ones to take them out. When they are out they are not expanding. Each case is different. Some require cemented ones and others can get away with removable ones.

- Q: I've tried hosing it down, sweeping etc. Nothing seems to work. Can anyone recommend a solution for my problem?

- Cement residue i presume what you really mean is the dusty stuff that keeps coming off of cement as it wears away for ever and ever. First if it's uneven lumps or spills and spots you have to pomice ( wear down the rough spot with pomice the cement with pomicingstone which usually has a wood handle and it is harder than cement especially poorly cheaply made cement used by builders andcontractors for extra profit. after dong that you go buy linceed oil and seal the floor with several coats lasts almost forever indoor. Second alternative is buy (very costly) slate and cement sealer. in 1974 it cost me $20. a gallon it took about 3 gallons to do 1100 sq. foot. basement. many builders mix too much sand and not enbough cement to make Concrete

- Q: I have a art studio that I am creating from the gound up. I don't have much money I need to do most every thing myself. A friend who was redecorating her kitchen gave me her cabnets that she took out the problem is the counter tops are in real bad shape. I would love to do a cement counter top as they will take a lot of abuse from all my projects.

- I saw this done on HGTV once by novice house flippers. At first I was like WHAT?? Cement countertops in a kitchen?? But the results were amazing and beautiful. But beware, it looked like it was a VERY difficult project because they had no experience with it. I hope you can do it! Good luck!

1. Manufacturer Overview

| Location | Guangdong,China (Mainland) |

| Year Established | 2011 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia; Domestic Market |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Foshan new port, Shenzhen yantian port, Guangzhou huangpu port |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese, Spanish, Portuguese, Arabic, Russian |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Cement Tile with Super High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meters m²

- Supply Capability:

- 5,000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords