Vietnam Handmade Cement Tile Language Option French

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meter/Square Meters m²

- Supply Capability:

- 5,000 Square Meter/Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

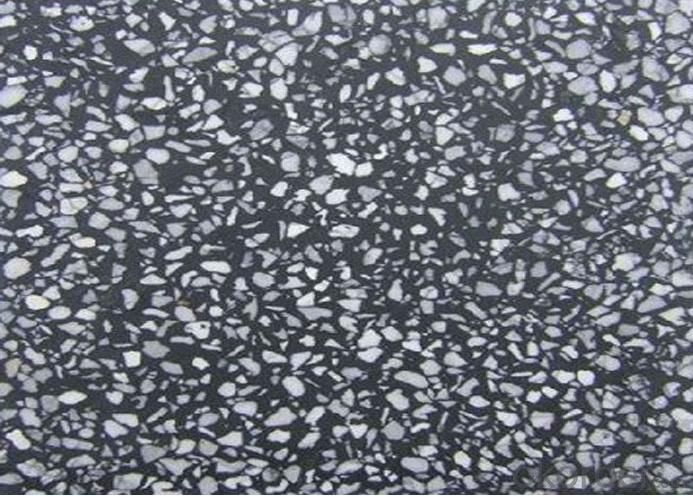

Vietnam Handmade Cement Tile

Water Absorption: <= 7%

Abrasion: +0.45gr/Cm2

Weight: 1200gr +/- 50gr

Elasticity: 1.200N min

This is encaustic cement tile, a produce of HANDMADE process created by Skillful Artisant from Vietnam, a country has 100s of Year in making encaustic cement tiles, this production in Vietnam is among the best quality in the world. Inheritating long tradition of making encaustic cement tile together with bring new modern technique to production, our Cement tiles have been produced and controlled under the best conditions to guarantee stable quality for all production batches. Basic material are marble powder and pigment, environmental friendly

All patterns and Colors can be customized

Available sizes from 50x50mm to 400x400mm which thickness ranging from 12mm till 25mm

Technical Specifications and Technological Parameters

Specs:

Length 200mm +/-0.5mm

Width 200mm +/-0.5mm

Height 15mm +/-1.0mm

Top Layer 3mm +/-0.1mm

Technological Parameters:

Weight 1200 gr +/- 50gr

Elasticity 1.200 Newton minimum

Shock resistance 30 times minimum

Water Absorption <= 7%

Abrasion +0.45 gr/Cm2

This is ideal material from indoor using or interior which is suitable for restoration of old building or for luxurious building such as hotels, restaurants, cafe or even for boutique or cottage house.

Our capacity: 5,000m2 per month equally to 8 containers 20ft per month.

- Q: Trivia question:: If trees are for humidity -- water is for moisture - what is cement for?

- Cement is for hardenng things togther.

- Q: Final setting time of cement...?

- Cement should set up hard enough to walk on in about 8-12 hours. To cure properly, it must be kept wet, and will reach 80% of its maximum strength in 3 days. To make really strong cement, keep it wet for at least 3 weeks. Do not let it dry out at all in that time. Cement, kept continuously wet, will continue to harden for 20 years.

- Q: My basement shower is basically just a cement slab with a drain and fiberglass walls. What's a rough ballpark cost estimate to tear out the cement shower and replace it with a modern glass stall and/or a tile shower?

- By cement slab you refer to the concrete basement floor with a drain in it? Nothing to tear out. A contractor will install a shower pan. Either custom made or a prefab pan and tie into the existing drain. If you want to relocate the shower then he will jack hammer up the slab and run the drain. Save money by having the shower in the same place. For just the shower pan and walls framed, covered with backer board, tile tie into existing hot and cold water supply figure about $4000. If you want to use custom materials like granite and limestone tiles add $1000. Also plan to install an exhaust fan for the steam. If you can be happy with a prefab fiberglass surround it will be half the cost.

- Q: in case of setting and hardening of cement, the first thing is stiffening

- Concrete is composed of cement and gravel/stone. When you add water to cement you get a chemical reaction called hydration. That reaction causes the cement to harden over time. The most common reaction that is similar is epoxy glue. Now, don't get me wrong, epoxy glue is NOT hardening because of hydration like cement. The bond in epoxy is an entirely chemical bond. But they are similar because as the epoxy hardens it goes thru a similar process. At first, it's liquid, then the liquid begins to stiffen and then hardens. Remember when you read the label on Epoxy that it has a hardening time (typically it's either 5 minute epoxy or 1 hour epoxy). But as you read on you find that it develops it's maximum strength over a period of 24 hours. As the epoxy dries it first stiffens.

- Q: There's this movie I saw a while ago but I forgot the title. I don't remember what it is about either except that it is something about a crazy man and a haunted place I think or something like that and people are locked in dark underground basements and buried in wet cementI remember how the movie starts though: A little girl who was locked in an underground room and then there was wet cement being poured into the room. She screamed and then died.And then I think the rest of the movie was that happening to other people.Any help?

- I watched this a few nights ago on On Demand (for free) and plan to watch it several more times if possible. The movie does open with a little girl sealed inside walls, then cement begins pouring in. The scene cuts away just as only her face is out of the muck~a very chilling moment!

- Q: the house is from 1959. Before I bought it the owners re-landscaped without any consideration for water flow thus causing the basement to have seepage through the walls. I fixed the water flow issue (1.5 years dry) but now I have painted cement walls that have paint pushed out/peeling with a few visible cracks and wonderful mineral deposition. I really don't want to spend the time with the metal wire brush to strip the paint off so I would like to just use hydraulic cement over the whole wall and then use a water sealing paint over the top. Is this a good idea? other suggestions?

- That sounds more time consuming than just scraping off the peeling paint..... Here's 1 problem w/your approach, latex paint dries so fast that it actually creates a vacuum effect in doing so, which means that as it dries it'll pull off the surface anything that's not firmly attached, which is why prep work's so important to longevity. You won't immediately notice this happening, but w/the passage of time you'll be back to the peeling wall in spades. I've never heard of skim-coating w/hydraulic cement, but I've done plenty of patching plaster walls w/plaster of paris, what immediately comes to mind are the inherent problems w/working in a medium that sets up so quickly, I can't imagine how you'd get a whole wall covered looking even satisfactory (but I'm pretty picky, I figure when people are paying me I'm obliged to do a better job than they could've) w/out going insane in the process. I learned the trick to plaster, but I don't know the chemistry of hydraulic cement well enough to find a retardant for it. Anyways, I know prep-work sucks, but often it's just easiest to do it get it over with (start w/a stiff putty knife, by the way) rather than inventing a new process having to deal w/a long string of learning curves as you go. The first question that came to mind w/your question is have you ever skim-coated anything before so that you'd have even a vague idea of what you're getting yourself into potentially, but if you must create, than by all means go forth!

- Q: 1.steel2.cement3.sand4.lime

- Lime and silica make about 85% of the mass of cement. However, lime by itself is not used in the production of Portland cement concrete mixtures. Hydrated lime is usually used in the production of asphaltic concrete mixtures. See the links below for more information.

- Q: doing a red brick fireplace at home.what sand/cemnt ratio should i use?

- 7 t0 9 full shovels of sand half bag of cement one shovel full of portland dry mix then add water an mix thoughrly

- Q: Do cement finishers often work long hours?

- if they have a girl friend on the side, the hours can be quite long!

- Q: I have got some chemistry prep and one of the question are ' How do u make cement ? ' Please could you help ! thanks :)

- look up Portland cement, it'll say the ratios of compounds needed. more or less just dry mix, add water, mix some more = cement.

1. Manufacturer Overview

| Location | Guangdong,China (Mainland) |

| Year Established | 2011 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia; Domestic Market |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Foshan new port, Shenzhen yantian port, Guangzhou huangpu port |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese, Spanish, Portuguese, Arabic, Russian |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Vietnam Handmade Cement Tile Language Option French

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meter/Square Meters m²

- Supply Capability:

- 5,000 Square Meter/Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords