High Quality Cement Polypropylene Fibers

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

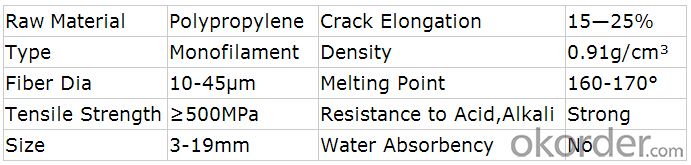

1,Specification of High Quality Cement Polypropylene Fibers

2,Introduction of High Quality Cement Polypropylene Fibers

Polypropylene fiber is also called engineering fiber, concrete fiber, anti-cracking fiber,synthetic fiber or plastic fiber.

We use high tenacity polypropylene resin as the raw material and produce with special technics. Putting the pp fiber into concrete or mortar can control the microcrack caused by such factors as the plasticity contraction, air shrinkage and temperature change. Great prevention of cracks-being, improvement of the features of anti-cracks and permeation-resistance, shock and earthquake proof, all these have been good evidence for the wide usage of pp fiber--finish coat of road and bridge, mining and tunnel construction, railroad, high-rise building, consolidation of side, fire-protection infrastructure, concrete-mending, industrial civil use engineering, wall, basement, waterproof project of pool and roof garden, kinds of prefabricate concrete products etc.

3, Package of PP Staple fiber

1kg/plastic bag, 20pastic bags/woven bag.

1x20' QTY: 9-10 Tons

1x40HQ QTY: 22-23Tons

allowing more or less clause.

4, Images of the Fiber

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of PP related product that used as the raw material of textile, automotive interior and constuction projects etc. Have been in this field for many years, with rich experience.

2> What's the MOQ?

1x20'GP or1x40'HQ will be better as the price would be economical based on full container load.

3>How long can we receive the product after purchase?

It takes about 1 to 2 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: 60% polyester fiber and 35% cotton, will there be static electricity?

- Fabric factory should be antistatic treatment, the cloth will not be processed after the static electricity. But chemical fiber clothes are more likely to get static, especially in dry winters

- Q: What functions can the fiber rotary drum filter play in the sewage treatment process?

- The fiber rotary drum filter is mainly the process of physical filtration. The filtration and filtration of hydrophobic pollutants are carried out by filtering cloth whose filter precision is less than 10 microns.

- Q: Do you have two kinds of eyelashes fiber, white and black?

- Yes, there are two kinds of eyelash fiber, white and black.

- Q: Polyester fiber shoes how to maintain, a little pilling, and a bit dirty?

- Polyester fabric is not wearable, easy pilling, generally not used as shoe material, special polyester fiber except

- Q: Which is good, MDF or particleboard? Why?

- [] the whole board density board properties is the same, its plasticity is good, can fingerskrouters various linear, but the density of plate bonding force between layers is relatively poor, the end of the play when drilling, easy to crack layer

- Q: Cotton, silk, nylon, fiber...... What are the inclusions and the differences?

- Silk and Tencel: silk is a natural protein fiber, divided into silk and tussah silk; silk for indoor bar cocoonery silk, tussah silk stocking for outdoor. Mulberry silk is more white and better performance than tussah silk.

- Q: What's the difference between polyester fiber and viscose fabric? Which cost is higher?

- Simple speaking is the first viscose cotton linter (you can also use other) made of pulp board, and pulp board after smashing into the caustic soda made of alkali cellulose, alkali cellulose, carbon disulfide, reaction of caustic soda alkali cellulose xanthate.

- Q: Cotton and polyester fiber with the advantages and disadvantages of Aaron

- Cotton fiber is a natural plant cellulose fiber, moisture absorption, breathable and comfortable, but the appearance of flat, stiff, easy to wrinkle.

- Q: What is involved?

- In recent years, viscose appeared a new high-grade varieties of Tencel, bamboo fiber. Viscose is of cotton or other natural fiber as raw materials for the production of cellulose fibers. In 12 main textile fiber, viscose moisture with human skin physiological requirements, with smooth cool, breathable, antistatic, dyeing flowery characteristics. Viscose fiber is one of the oldest species. In 1891, Crosby (Cross), Bevan (Bevan) and Beadle (Beadle) made of cellulose sodium xanthate solution first to cotton as raw material, the solution viscosity is large, thus the name "viscose". When the viscose is acid, the cellulose is re - precipitated. According to this principle, in 1893 it developed into a method of making cellulose fibers called viscose fibers". By 1905, Miller (Muller) had invented a coagulating bath composed of dilute sulfuric acid and sulfate, which realized the industrialized production of viscose fiber

- Q: Is not pure cotton will pilling it?

- Many people may not believe it. Everyone thinks that only the fabric of chemical fiber can be used for pilling, while pure cotton is absolutely no pilling. Therefore, in reality, once encountered clothing pilling, the first reaction is that the fabric is not pure cotton, doped with other chemical fiber ingredients.

Send your message to us

High Quality Cement Polypropylene Fibers

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords