Aluminum T-Slot Extrusion Profiles for Embossed Warm Protection CC Aluminum Strip

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3400 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

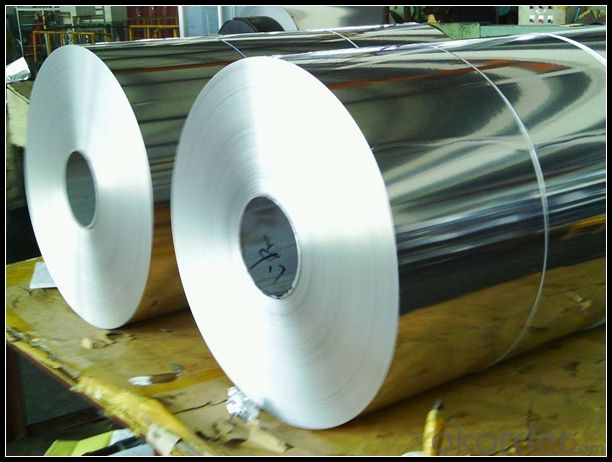

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Are aluminum profiles suitable for automotive heat exchangers?

- Yes, aluminum profiles are suitable for automotive heat exchangers. Aluminum offers several advantages that make it an ideal material for heat exchanger applications in automobiles. Firstly, aluminum has excellent thermal conductivity, which means it can efficiently transfer heat from one medium to another. This property allows aluminum heat exchangers to effectively dissipate heat generated by the engine, transmission, or other components in the vehicle. Secondly, aluminum profiles are lightweight yet strong, making them a preferred choice in the automotive industry where weight reduction is crucial for improved fuel efficiency and performance. The use of aluminum heat exchangers can contribute to overall weight reduction, leading to better handling, acceleration, and energy efficiency. Additionally, aluminum is highly corrosion-resistant, even in harsh environments, making it suitable for automotive applications. This resistance to corrosion ensures the longevity and reliability of the heat exchangers, reducing maintenance and replacement costs. Furthermore, aluminum profiles can be easily manufactured and formed into complex shapes, allowing for customized designs that fit specific automotive requirements. This flexibility in design enables efficient use of available space and maximizes the heat exchange surface area, enhancing overall performance. In conclusion, aluminum profiles are well-suited for automotive heat exchangers due to their excellent thermal conductivity, lightweight yet strong characteristics, corrosion resistance, and flexibility in design. These qualities make aluminum an ideal choice for effectively managing heat in vehicles, contributing to improved performance, fuel efficiency, and durability.

- Q: Are aluminum profiles suitable for greenhouse structures?

- Yes, aluminum profiles are highly suitable for greenhouse structures. They are lightweight, durable, and resistant to rust and corrosion, making them ideal for outdoor environments. Additionally, aluminum profiles offer excellent strength and flexibility, allowing for easy customization and assembly of greenhouse structures.

- Q: Can aluminum profiles be used in signage or display applications?

- Yes, aluminum profiles can be used in signage or display applications. Aluminum profiles are versatile and lightweight, making them ideal for creating durable and visually appealing signs and displays. They can be easily cut, shaped, and joined together to create custom frames, panels, and structures for various signage and display purposes. Aluminum profiles also offer excellent corrosion resistance, ensuring that the signs or displays remain intact and attractive even in outdoor or high-moisture environments. Additionally, aluminum profiles can be powder coated or anodized to provide a wide range of color options, allowing for branding or customization. Overall, aluminum profiles offer a reliable and cost-effective solution for signage or display applications, providing both functionality and aesthetics.

- Q: This question asks for a list of various materials that are used in the production of aluminum profiles.

- <p>Aluminum profiles are primarily made from aluminum alloys, which are composed of aluminum combined with other elements to enhance their properties. Common materials used include 6063 aluminum alloy, known for its excellent extrudability and weldability, making it ideal for a wide range of applications. 6061 aluminum alloy is also used for its high strength and good corrosion resistance, suitable for structural components. Other alloys such as 6082 and 7075 are utilized for their superior strength-to-weight ratios, often found in aerospace and automotive industries. Additionally, aluminum profiles may incorporate materials like magnesium, silicon, copper, and manganese to achieve specific mechanical properties or corrosion resistance tailored to particular applications.</p>

- Q: This question asks for an overview of the various types of aluminum profiles that are typically utilized in construction projects.

- <p>Aluminum profiles used in construction come in various types, each serving specific purposes. Common types include: 1. Extruded Profiles: These are the most common, created by forcing aluminum through a die to achieve desired shapes. 2. Structural Profiles: Used for structural integrity in buildings, such as beams and columns. 3. Fa莽ade Profiles: Specifically designed for the exterior cladding of buildings. 4. Window and Door Profiles: For frame construction in windows and doors. 5. Fastening Profiles: Used for joining and fixing other aluminum components. 6. Special Profiles: Custom-made for unique applications. 7. Decorative Profiles: For aesthetic purposes, enhancing the appearance of structures. Each type has specific properties and is chosen based on the structural requirements and design considerations of the construction project.</p>

- Q: How do aluminum profiles perform in terms of static electricity discharge?

- Aluminum profiles have excellent static electricity discharge properties. Due to their high electrical conductivity, aluminum profiles are effective in dissipating static charges that may build up on their surface. This helps to prevent the accumulation of static electricity, which is particularly important in industries where electrostatic discharge can cause damage to sensitive electronic components or pose a risk to safety. The conductivity of aluminum profiles allows for the easy grounding of any static charges, ensuring a safe working environment. Additionally, aluminum profiles are often used in the construction of ESD (electrostatic discharge) protective equipment and structures, further highlighting their effectiveness in managing static electricity. Overall, aluminum profiles are highly reliable in terms of static electricity discharge, making them a preferred choice in various industries where static control is necessary.

- Q: What is a pouring type heat insulation aluminum profile?

- The utility model has the advantages of compact structure, artful appearance, lighting area, high strength of the profile, high heat insulation property, high material ratio and aluminum saving.

- Q: How do aluminum profiles contribute to sustainable infrastructure development?

- Aluminum profiles play a significant role in promoting sustainable infrastructure development in various ways. Firstly, aluminum is a lightweight material, which means it requires less energy during transportation and installation compared to other heavy materials like steel. This reduces greenhouse gas emissions and the overall carbon footprint associated with construction projects. Additionally, aluminum profiles have excellent durability and corrosion resistance, allowing them to withstand harsh environmental conditions and extend the lifespan of infrastructure projects. This durability reduces the frequency of repairs and replacements, leading to reduced waste generation and resource consumption. Furthermore, aluminum is a highly recyclable material, with the ability to be infinitely recycled without losing its original properties. This promotes a circular economy by minimizing the need for primary aluminum production and reducing the demand for raw materials. The recycling process of aluminum also requires significantly less energy compared to primary production, resulting in reduced energy consumption and lower emissions. Moreover, aluminum profiles offer design flexibility and compatibility with various construction methods, allowing for innovative and sustainable infrastructure solutions. They can be easily integrated into energy-efficient systems, such as solar panels or LED lighting, to further enhance sustainability. Overall, the use of aluminum profiles in infrastructure development contributes to a more sustainable built environment by reducing energy consumption, minimizing waste generation, promoting recycling, and enabling the implementation of energy-efficient solutions.

- Q: What are the different welding options available for aluminum profiles?

- Some of the different welding options available for aluminum profiles include tungsten inert gas (TIG) welding, metal inert gas (MIG) welding, friction stir welding, and laser welding. Each method has its own advantages and is suitable for different applications and thicknesses of aluminum profiles. TIG welding provides precise control and is commonly used for thin aluminum profiles, while MIG welding is faster and more suitable for thicker profiles. Friction stir welding is a solid-state joining process that can create high-quality welds with minimal distortion. Laser welding offers high energy density and is often used for precision welding of aluminum profiles.

- Q: Can aluminum profiles be used in the construction industry?

- Yes, aluminum profiles can be used in the construction industry. Aluminum profiles are lightweight, durable, and corrosion-resistant, making them suitable for various construction applications. They are commonly used in the fabrication of windows, doors, curtain walls, and structural framing systems. Aluminum profiles offer excellent strength-to-weight ratio, allowing for the creation of large and intricate structures while minimizing the overall weight. Additionally, they can be easily formed into different shapes and sizes, providing flexibility in design and construction. The thermal conductivity of aluminum profiles is also advantageous, as it allows for efficient insulation and energy savings. Overall, aluminum profiles are a popular choice in the construction industry due to their versatility, durability, and aesthetic appeal.

Send your message to us

Aluminum T-Slot Extrusion Profiles for Embossed Warm Protection CC Aluminum Strip

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3400 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords