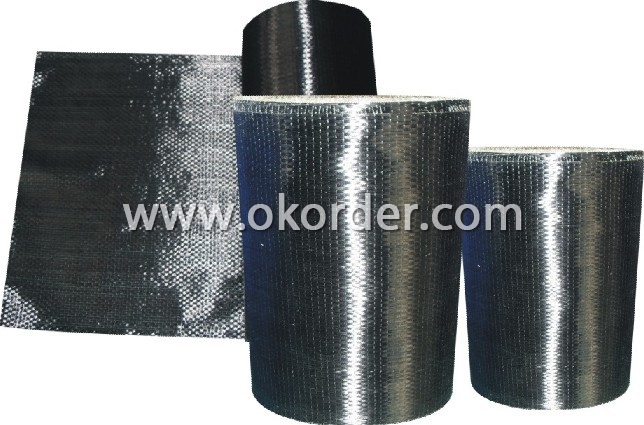

Carbon Fiber Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2Ton kg

- Supply Capability:

- 500Ton Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Carbon Fiber Tape:

Temperature: less than 550 degree C;

Width: 10mm to 150mm, on customers request;

Thickness: 1.5mm to 6.0mm, as your requirements.Carbon fiber tape is woven by carbon fiber, used as insulation materials and an excellent substitute for asbestos tape. High adhesive, resistant to abrasion and moisture, economical, high tensile strength, long storage.

Application of Carbon Fiber Tape:

Industrial thermal insulation, piping and electrical cable lining, shielding against heat radiation, high temperature oven door curtain, flange jointing with bolts, friction reinforcement materials, etc.

General Data of Carbon Fiber T400

Weaving Style: Unidirectional, Plain, Twill

Input Available: 3k, 6k, 12k Carbon fiber

Weight: 15 0 ~ 600g / m2

Roll length: To be specified

Storage of Carbon Fiber Tape

It is recommended that the carbon fiber fabric are stored in a cool and dry environment. Recommended temperature range of storage is between 10 ~ 30 degree and relative humidity between 50 ~ 75%.The carbon fiber fabric should remain in the packaging until just prior to use.

Packaging & Delivery of Carbon Fiber Tape

Product is manufactured in form of a roll wound on a paper tube and then packed in a plastic film and placed within a cardboard carton. Rolls can be loaded into a container directly or on pallets.

- Q: What is the role of carbon in respiration?

- The role of carbon in respiration cannot be overstated, as it serves as a vital element in organic molecules like glucose. When respiration takes place, glucose undergoes a breakdown with the presence of oxygen, resulting in the production of ATP energy. The carbon atoms found in glucose are oxidized, thereby releasing electrons that eventually transfer to oxygen and form carbon dioxide (CO2) as a byproduct. This entire process, which is referred to as cellular respiration, is universal among all living organisms and is indispensable for generating the energy necessary for various cellular activities. The absence of carbon would render respiration impossible and prevent the generation of energy essential for growth, movement, and other vital life functions. Additionally, the carbon dioxide generated during respiration is released into the atmosphere and plays a critical role in the carbon cycle, which contributes to the regulation of Earth's climate and supports plant growth through photosynthesis.

- Q: How does carbon affect the formation of tornadoes?

- Carbon does not have a direct effect on tornado formation. Tornadoes primarily occur when warm, moist air from the surface interacts with cold, dry air from higher levels of the atmosphere, creating strong upward drafts and rotating air columns. Carbon, as an element, does not have a significant role in this process. However, carbon emissions and human-induced climate change can indirectly impact weather patterns, including the frequency and intensity of tornadoes. The burning of fossil fuels, which releases carbon dioxide into the atmosphere, contributes to global warming. This, in turn, leads to changes in temperature and moisture patterns that can influence the conditions necessary for tornado formation. The increased levels of carbon dioxide in the atmosphere can cause the atmosphere to become more unstable, creating conditions favorable for severe thunderstorms that can produce tornadoes. Moreover, the warmer atmosphere with higher moisture content can provide more fuel for these storms, potentially making them stronger. It is important to note that the relationship between carbon emissions and tornadoes is complex and still an ongoing area of research. While there is a possibility of a connection between climate change and tornadoes, it is difficult to attribute individual tornadoes solely to carbon emissions, as tornadoes are influenced by various meteorological factors. In conclusion, carbon does not directly impact tornado formation, but the increased carbon emissions and resulting climate change can indirectly affect the conditions that contribute to tornado formation. Further scientific research is necessary to fully comprehend the relationship between carbon emissions, climate change, and tornado activity.

- Q: What are the potential uses of carbon nanomaterials in medicine?

- Due to their distinctive properties, carbon nanomaterials hold great promise in the field of medicine. One area where they could be utilized is in drug delivery systems. The efficient loading and release of therapeutic agents, made possible by their high surface area-to-volume ratio, enables targeted and controlled drug delivery. As a result, more effective treatments with fewer side effects can be achieved. Another potential application of carbon nanomaterials is in medical imaging. Carbon nanotubes and graphene, among others, possess excellent optical and electrical properties that can enhance imaging techniques like MRI and CT scans. This enhancement could result in improved accuracy and resolution, leading to better disease diagnosis and monitoring. Moreover, carbon nanomaterials exhibit antibacterial properties that can be harnessed for wound healing and infection control. They can effectively eliminate bacteria and prevent the formation of biofilms, which are often resistant to traditional antibiotics. This has the potential to revolutionize infection treatment, particularly for bacteria that have become resistant to antibiotics. Additionally, carbon nanomaterials hold promise in tissue engineering and regenerative medicine. Their biocompatibility, mechanical strength, and electrical conductivity make them suitable for creating scaffolds that support tissue growth and promote regeneration. They can also enhance the electrical stimulation of tissues, aiding in nerve regeneration and improving the functionality of artificial organs. Furthermore, carbon nanomaterials have been investigated for their ability to detect and monitor diseases at an early stage. Their unique electronic and optical properties can be leveraged in biosensors and diagnostic devices, enabling sensitive and specific detection of disease-associated biomarkers. While the potential applications of carbon nanomaterials in medicine are extensive, it is important to emphasize that further research and development are necessary to ensure their safety, efficacy, and long-term effects. Regulatory considerations and ethical concerns surrounding the use of nanomaterials in medicine also need to be addressed. Nevertheless, the promising capabilities of carbon nanomaterials offer hope for the future of advanced and personalized medical treatments.

- Q: What is the carbon content of 45# steel?

- The carbon content of 45# steel is about 0.42~0.50%. 45 steel is the term "GB", also called "oil steel"". Hot spot in the market; cold rolled gauge 1.0~4.0mm.

- Q: They include a cementite, two cementite, three cementite, eutectic cementite and eutectoid cementite, and compare their temperature, composition and morphology

- Two: cementite in iron graphite phase, carbon content more than 0.77%, in A (Fe + Fe3C) two-phase region precipitation of Fe3C is two times the cementite formation temperature in the eutectic temperature (1148 DEG C) and eutectoid temperature (727 DEG C), morphology of the mesh is a typical carbon content. From 0.77% to 6.69% is the typical composition range.

- Q: How is carbon used in the production of rubber?

- Carbon is widely used in the production of rubber due to its unique properties and its ability to enhance the overall quality and performance of rubber products. Carbon black, a form of elemental carbon produced by the incomplete combustion of hydrocarbons, is a key component in rubber manufacturing. Carbon black is added to rubber formulations to improve its strength, durability, and resistance to wear and tear. It acts as a reinforcing agent, providing increased tensile strength and abrasion resistance to the rubber. Carbon black particles interlock with the rubber polymer chains, reinforcing the overall structure of the material and making it more resilient. Additionally, carbon black helps improve the conductivity of rubber, making it useful in applications where electrical conductivity is required. It also enhances the UV resistance of rubber, protecting it from degradation caused by sunlight exposure. Carbon black can also improve the coloration and appearance of rubber products, giving them a deep black color. Furthermore, carbon black can be used as a filler in rubber compounds, reducing the overall cost of production while maintaining or even improving the mechanical properties of the rubber. By replacing a portion of the more expensive rubber polymer with carbon black, manufacturers can achieve cost savings without sacrificing the desired performance characteristics of the rubber. Overall, carbon plays a crucial role in the production of rubber by enhancing its strength, durability, conductivity, UV resistance, and appearance. Without carbon, rubber products would not possess the desired properties necessary for their intended applications.

- Q: What is the structure of a diamond, a form of carbon?

- The structure of a diamond, a form of carbon, consists of a three-dimensional arrangement of carbon atoms bonded together in a rigid lattice structure. Each carbon atom is covalently bonded to four neighboring carbon atoms, forming a tetrahedral arrangement. This strong and stable network of carbon atoms contributes to the diamond's exceptional hardness and high thermal conductivity.

- Q: How is carbon stored in the Earth's crust?

- Carbon is stored in the Earth's crust through various geological processes such as the formation of sedimentary rocks, the burial of organic matter, and the formation of fossil fuels. These processes involve the accumulation and preservation of carbon-rich material over millions of years, resulting in the storage of carbon in the form of minerals, organic compounds, and hydrocarbons within the Earth's crust.

- Q: What is carbon neutral construction?

- Carbon neutral construction refers to the process of designing, constructing, and maintaining buildings in a way that minimizes their carbon footprint and offsets any remaining emissions. This involves using sustainable materials, implementing energy-efficient systems, and utilizing renewable energy sources to achieve net-zero carbon emissions throughout the building's lifecycle.

- Q: What is carbon monoxide poisoning?

- High levels of carbon monoxide gas can be extremely dangerous, potentially causing fatal carbon monoxide poisoning. This condition occurs when an individual breathes in or comes into contact with this gas. Carbon monoxide, which is produced from burning carbon-based fuels like gasoline, natural gas, coal, and wood, is invisible, odorless, and tasteless. When carbon monoxide is inhaled, it enters the bloodstream and attaches itself to hemoglobin, the molecule responsible for carrying oxygen throughout the body. This attachment prevents oxygen from reaching vital organs and tissues, leading to oxygen deprivation or hypoxia. The symptoms of carbon monoxide poisoning can vary, depending on the duration and level of exposure. However, they often resemble flu-like symptoms, including headaches, dizziness, weakness, nausea, vomiting, confusion, and loss of consciousness. Prolonged exposure to high levels of carbon monoxide can cause severe brain damage, organ failure, and even death. If you suspect carbon monoxide poisoning, it is crucial to act swiftly. Get away from the source of exposure, seek fresh air, and contact emergency services for medical assistance. Moreover, it is essential to identify and resolve the source of carbon monoxide, such as faulty heating systems, blocked chimneys, or malfunctioning appliances, to prevent further exposure and ensure a safe environment. To avoid carbon monoxide poisoning, prevention is key. Regularly maintain and inspect fuel-burning appliances, install carbon monoxide detectors in homes and buildings, and ensure adequate ventilation to minimize the risk of exposure. Educating yourself and others about the dangers of carbon monoxide and the necessary precautions can save lives and protect individuals from this silent killer.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 20,000 |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9002:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 20% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Carbon Fiber Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2Ton kg

- Supply Capability:

- 500Ton Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords