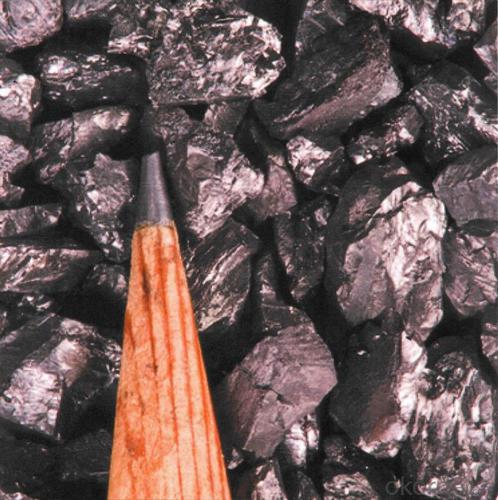

Calcined Anthracite Coal Low Sulphur for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications Calcined Anthracite Coal Low Sulphur for Steelmaking Carbon Additve low Ash,S,P Structure Calcined Anthracite Coal Low Sulphur for Steelmaking Shape: granule Dimensions: FC90-95% Product Type: Carbon Additive C Content (%): 90-95% MIN Working Temperature: - S Content (%): 0.5%MAX N Content (%): - H Content (%): 0.6%MAX Ash Content (%): 8.5%MAX Volatile: 2%MAX ADVANTAGE: low ash & sulfur COLOR: Black RAW MATERIAL: TaiXi anthracite Feature Calcined Anthracite Coal Low Sulphur for Steelmaking Specifications (%): Grade F.C Ash V.M Moisture S Size CR-95 ≥95 <4 <1 <1 <0.3 0-30mm CR-94 ≥94 <4 <1 <1 <0.3 CR-93 ≥93 <6 <1 <1 <0.4 CR-92 ≥92 <7 <1 <1 <0.4 CR-91 ≥91 <8 <1 <1 <0.4 CR-90 ≥90 <8.5 <1.5 <2 <0.4 Image Calcined Anthracite Coal Low Sulphur for Steelmaking FAQ: Calcined Anthracite Coal Low Sulphur for Steelmaking Why we adopt carbon additive? Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation. Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking. Advantage: Calcined Anthracite Coal Low Sulphur for Steelmaking 1.High quality and competitive price. 2.Timely delivery. 3.If any item you like. Please contact us. Your sincere inquiries are typically answered within 24 hours.

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

As buyer's request.

- Q: Something that seems to be used in the locomotive brake system. I haven't seen it, either. Who knows? It's better for the locomotive system to go back. Thank you!!

- When the skateboard wear to the limit, only in the maintenance of the daily locomotive can be replaced, so that although it is more troublesome, but it is always better than the replacement of contact wire.

- Q: What are the consequences of increased carbon emissions on economic stability?

- Increased carbon emissions have significant consequences on economic stability. One of the most notable impacts is the exacerbation of climate change, leading to more frequent and severe natural disasters such as hurricanes, floods, and wildfires. These events result in immense economic damage, including the destruction of infrastructure, loss of property, and disruption of supply chains. Furthermore, the effects of climate change, driven by increased carbon emissions, also have long-term economic implications. Rising sea levels threaten coastal cities and industries, leading to the potential displacement of populations and loss of valuable assets. Extreme heatwaves and droughts can damage agricultural productivity, affecting food security and increasing prices. These climate-related disruptions can destabilize economies, particularly in vulnerable regions heavily reliant on agriculture or tourism. Additionally, efforts to mitigate and adapt to climate change, such as transitioning to cleaner energy sources and implementing climate policies, require significant financial investments. This can strain government budgets and divert resources away from other socio-economic priorities, potentially leading to reduced funding for education, healthcare, and infrastructure development. Moreover, the economic consequences of increased carbon emissions extend beyond immediate climate-related impacts. The reliance on fossil fuels as the primary source of energy contributes to volatile oil prices, which can disrupt global markets and impact economic stability. As the world moves towards a low-carbon economy, industries heavily dependent on fossil fuels may face significant challenges, leading to job losses and economic dislocation. In summary, increased carbon emissions have far-reaching consequences on economic stability. The resulting climate change leads to more frequent and severe natural disasters, causing substantial economic damage. Furthermore, the need to respond to climate change through mitigation and adaptation efforts can strain government budgets and divert resources away from other essential sectors. Lastly, the reliance on fossil fuels contributes to volatile oil prices and poses long-term risks to industries tied to these resources. Addressing carbon emissions is crucial for safeguarding economic stability and promoting sustainable growth.

- Q: How does carbon contribute to the color of gemstones?

- Gemstone color is influenced by carbon, a vital element. Carbon's presence in a gemstone's crystal lattice structure allows it to absorb specific light wavelengths and reflect others, resulting in its distinct color. The arrangement of carbon atoms within the gemstone's structure can excite electrons, leading to the absorption of certain colors of light. This absorption process determines the gemstone's color, as the remaining wavelengths are reflected back to our eyes. For instance, diamonds can exhibit color variations, ranging from colorless to yellow or even fancy shades like blue or pink, due to the presence of nitrogen impurities. Similarly, in gemstones like rubies and sapphires, traces of carbon produce a spectrum of colors, spanning from red to blue, depending on the concentration and arrangement of these carbon impurities. Thus, carbon plays a vital role in the color and visual appeal of diverse gemstones.

- Q: What is carbon fixation?

- Carbon fixation is the process by which carbon dioxide from the atmosphere is converted into organic compounds, primarily through photosynthesis in plants.

- Q: How long will it last? 10National Day would like to do carbon baking ribs at home, how to do, how to marinate? For how long?.. Don't copy sticky posts. Now, tour TV's "eating meat" on earth is recorded in a grilled pork chop, wondering how that is done

- Use 1 tablespoons olive oil, 2 cloves of garlic, 2 tablespoons fresh Brazil, half lemon juice, 1 tablespoon Thyme, 1 jin spareribs, a little salt and black pepper method, 1. whole ribs washed, put the ingredients, marinated pork ribs 2 hours. 2., with charcoal fire roast ribs, while baking and brush ingredients, baked until golden. 3. if the oven can be placed in the oven 180C temperature, bake until golden

- Q: What are the consequences of increased carbon emissions on tourism industry?

- The tourism industry is greatly affected by the significant consequences of increased carbon emissions. One prominent result is the deterioration of natural landscapes and ecosystems that attract tourists. Carbon emissions contribute to global warming, which leads to higher temperatures, melting glaciers, and more frequent extreme weather events like hurricanes and droughts. These environmental changes can cause the destruction of iconic landmarks, such as coral reefs or national parks, which are often the main attractions for tourists. Additionally, increased carbon emissions contribute to air pollution, which can have negative effects on air quality in popular tourist destinations. This poor air quality can lead to respiratory problems and other health issues for both tourists and local populations, making these places less desirable to visit. Moreover, the degradation of natural environments due to carbon emissions can also harm wildlife, resulting in a decline in biodiversity. This loss of wildlife can reduce the appeal of ecotourism destinations, which heavily rely on diverse flora and fauna. Furthermore, the tourism industry heavily depends on transportation, which is a major source of carbon emissions. The use of fossil fuels in planes, ships, and cars contributes to the industry's overall carbon footprint. As countries strive to decrease their carbon emissions, they may enforce stricter regulations or impose taxes on air travel, making it more expensive and less accessible for travelers. This can impact the number of tourists visiting different destinations and impede the growth of the tourism industry. Lastly, the consequences of increased carbon emissions extend beyond environmental factors. Climate change and extreme weather events can disrupt travel plans, resulting in cancellations and financial losses for both tourists and businesses in the tourism industry. Additionally, destinations that heavily rely on winter tourism, like ski resorts, may face challenges due to shorter snow seasons or inconsistent snowfall patterns caused by climate change. In conclusion, increased carbon emissions have dire consequences on the tourism industry. From the degradation of natural landscapes and ecosystems to the impact on air quality and wildlife, the effects of carbon emissions can discourage tourists from visiting certain destinations. Furthermore, the industry's reliance on transportation contributes to its overall carbon footprint, potentially leading to increased costs and limited accessibility for travelers. Climate change-related disruptions and financial losses further exacerbate the challenges faced by the tourism industry.

- Q: What are the consequences of increased carbon emissions on human migration patterns?

- Increased carbon emissions can have significant consequences on human migration patterns. One major consequence is the displacement of populations due to the impacts of climate change, such as rising sea levels, extreme weather events, and loss of agricultural productivity. This can lead to forced migration, as people seek safer and more habitable areas. Additionally, the impacts of climate change can exacerbate existing social, economic, and political tensions, potentially leading to conflict and further displacement. Furthermore, the strain on resources and infrastructure caused by increased carbon emissions can also contribute to migration, as communities may struggle to meet basic needs. Overall, increased carbon emissions can disrupt human migration patterns and create complex challenges for individuals, communities, and governments worldwide.

- Q: How does carbon affect the fertility of soil?

- Soil fertility relies on carbon, which has a significant impact on various soil properties and processes. The addition of carbon to the soil improves its structure and ability to hold water. Organic matter, abundant in carbon, serves as a food source for microorganisms. These microorganisms play a crucial role in nutrient cycling and soil aggregation as they break down organic matter into simpler compounds. This process releases essential nutrients that plants can readily access. Furthermore, carbon acts as a sponge, preventing the leaching of nutrients like nitrogen and thereby increasing their availability for plants. Additionally, soils rich in carbon have higher cation exchange capacity, enabling them to retain and release nutrients more efficiently. By maintaining and increasing soil carbon levels, we can enhance soil fertility, facilitate plant growth, and support sustainable agricultural practices.

- Q: What is carbon fiber and how is it used?

- Made from thin strands of carbon atoms bonded together in a specific pattern, carbon fiber is a material that is both lightweight and incredibly strong. Its exceptional strength-to-weight ratio surpasses that of steel, while its weight is significantly lighter. The unique properties of carbon fiber make it widely used across various industries and applications. In the aerospace industry, it is a common choice for constructing aircraft components such as wings, fuselage sections, and engine parts. Its strength and lightness contribute to better fuel efficiency and overall performance. The automotive industry heavily relies on carbon fiber for manufacturing high-performance vehicles. Carbon fiber reinforced composites are utilized in the production of body panels, chassis components, and interior trims. By reducing the overall weight of vehicles, carbon fiber not only enhances structural integrity but also improves handling and fuel efficiency. Sports equipment manufacturers also incorporate carbon fiber into the production of sporting goods like tennis rackets, golf clubs, bicycles, and hockey sticks. The material's strength and stiffness result in improved performance, increased power transfer, and enhanced durability. Additionally, carbon fiber finds applications in the construction industry for reinforcing concrete structures, as well as in the manufacturing of wind turbine blades, boat hulls, and various other industrial components. Overall, carbon fiber is the preferred choice in industries requiring high-performance materials due to its exceptional strength, lightweight nature, and versatility. As advancements in manufacturing techniques and cost reduction efforts continue, its use is expanding to a wider range of applications.

- Q: How is carbon formed in stars?

- Nuclear fusion is the process by which carbon is produced in stars. Hydrogen atoms in the star's core go through a series of fusion reactions, eventually combining to form helium. This fusion process emits a massive amount of energy and is responsible for the heat and light emitted by stars. As the star's core grows hotter and the pressure increases, helium atoms begin to fuse, creating heavier elements. At a certain point, three helium nuclei can come together to form a carbon nucleus. This process, called the triple alpha process, requires specific conditions, including high temperature and pressure, for it to occur. The triple alpha process relies on the fact that carbon-12 possesses a distinct energy level that allows three helium nuclei to unite and create a stable carbon nucleus. This is due to the perfect alignment of carbon-12's energy level with those of helium nuclei, enabling them to overcome electrostatic repulsion and fuse together. Once carbon is generated in the star's core, it can undergo further fusion reactions, resulting in the creation of even heavier elements like oxygen and nitrogen. These elements are vital building blocks for the formation of planets, including our own Earth, as they eventually get expelled into space during the later stages of a star's evolution.

Send your message to us

Calcined Anthracite Coal Low Sulphur for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords