Carbon Additve Carbon Raiser for Steel Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

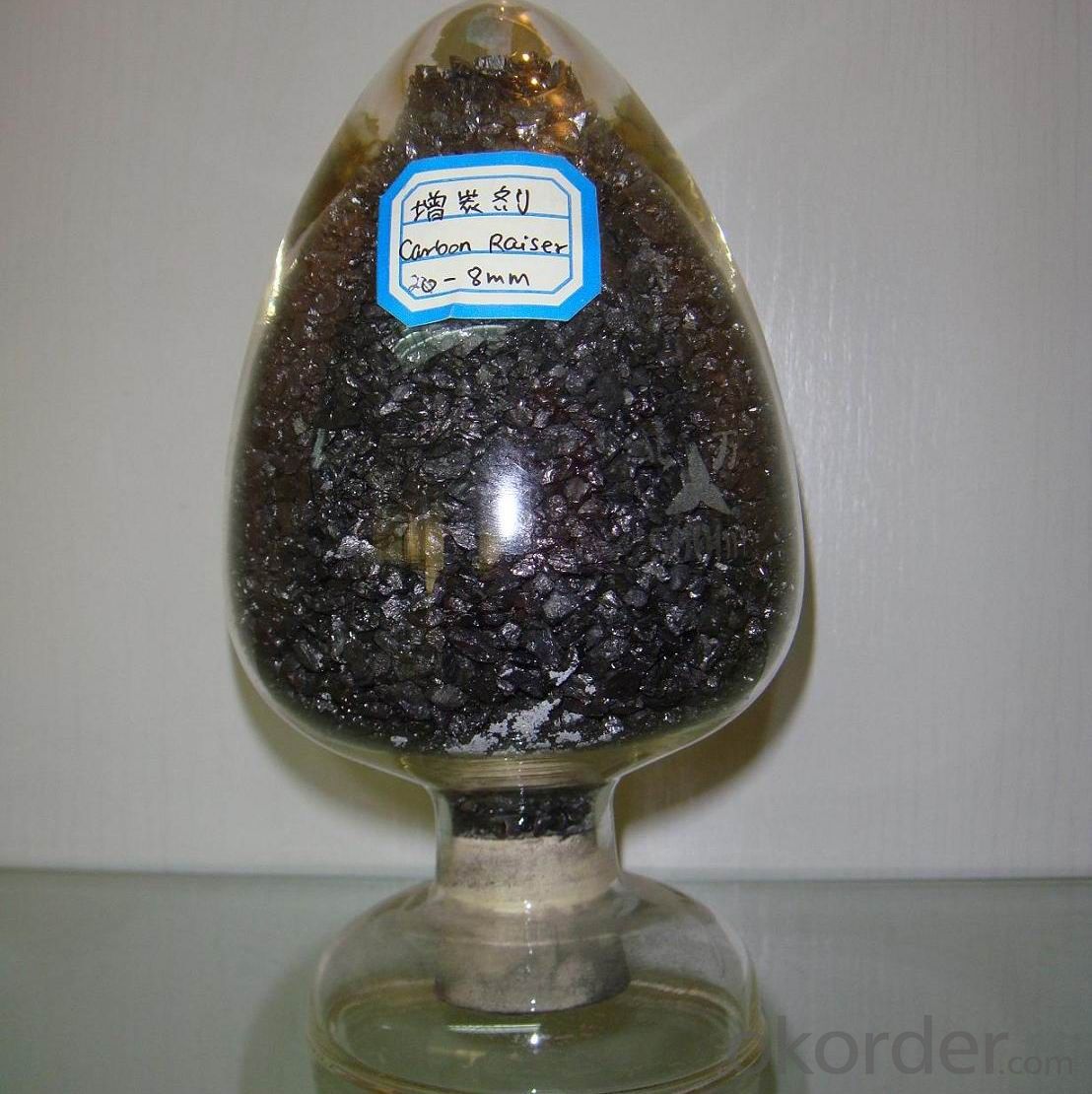

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications

Carbon Additve Carbon Raiser for Steel Industry

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Carbon Additve Carbon Raiser for Steel Industry

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Feature

Carbon Additve Carbon Raiser for Steel Industry

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4 | <1 | <1 | <0.3 | 0-30mm |

CR-94 | ≥94 | <4 | <1 | <1 | <0.3 | |

CR-93 | ≥93 | <6 | <1 | <1 | <0.4 | |

CR-92 | ≥92 | <7 | <1 | <1 | <0.4 | |

CR-91 | ≥91 | <8 | <1 | <1 | <0.4 | |

CR-90 | ≥90 | <8.5 | <1.5 | <2 | <0.4 | |

Image

Carbon Additve Carbon Raiser for Steel Industry

FAQ:

Carbon Additve Carbon Raiser for Steel Industry

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Carbon Additve Carbon Raiser for Steel Industry

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: What are the impacts of carbon emissions on wildlife?

- Carbon emissions have a significant impact on wildlife and their ecosystems. One of the most direct impacts is through climate change caused by the release of greenhouse gases, primarily carbon dioxide, into the atmosphere. As carbon emissions contribute to the warming of the planet, it disrupts the delicate balance of ecosystems and affects biodiversity. One of the major consequences of climate change for wildlife is the alteration of habitats. Rising temperatures can lead to the loss of critical habitats such as coral reefs, mangroves, and polar ice caps, which are home to numerous species. This loss of habitat can result in the displacement or extinction of vulnerable species, disrupting entire food chains and ecological systems. Additionally, climate change can affect the timing and availability of resources for wildlife. Shifts in temperature and precipitation patterns can disrupt the timing of migration, breeding, and hibernation for many species. This can lead to mismatches between the availability of food sources and the needs of wildlife, ultimately impacting their survival and reproduction. Another impact of carbon emissions on wildlife is ocean acidification. When carbon dioxide dissolves in seawater, it forms carbonic acid, which lowers the pH of the oceans. Acidic waters can negatively affect marine organisms, particularly those with calcium carbonate shells or skeletons, such as corals, oysters, and certain types of plankton. This disruption in the marine food chain can have cascading effects on other marine species, including fish, birds, and marine mammals. Furthermore, carbon emissions contribute to air pollution, which can have direct impacts on wildlife. Pollutants such as nitrogen dioxide and sulfur dioxide can harm respiratory systems, impairing the health and reproductive success of animals. This can be particularly detrimental for species living in or near urban areas with high levels of pollution. In conclusion, carbon emissions have far-reaching impacts on wildlife. Climate change caused by carbon emissions disrupts habitats, alters resource availability, and contributes to ocean acidification. These changes can lead to the displacement or extinction of species, disrupt entire ecosystems, and impact the health and survival of wildlife. It is crucial to reduce carbon emissions and implement sustainable practices to mitigate these impacts and conserve biodiversity.

- Q: How is carbon used in the manufacturing of electronics?

- Carbon is used in several ways in the manufacturing of electronics. One of the primary uses of carbon in electronics is as a key component in the production of carbon nanotubes. These nanotubes have exceptional electrical conductivity and mechanical strength, making them ideal for use in various electronic devices. For instance, carbon nanotubes can be used to create high-performance transistors, which are essential components in computer chips. Additionally, carbon is utilized in the manufacturing of batteries for electronic devices. Carbon-based materials, such as graphite, are commonly used as the anode material in lithium-ion batteries. This is because graphite can store and release lithium ions efficiently, allowing for the rechargeable nature of these batteries. Furthermore, carbon is employed in the production of conductive coatings and inks used for printed circuit boards (PCBs). Carbon-based materials, such as carbon black or carbon nanotubes, are added to these coatings and inks to enhance their electrical conductivity. This enables the proper flow of electrical signals throughout the circuitry of electronic devices. In summary, carbon plays a crucial role in the manufacturing of electronics. It is used in the production of carbon nanotubes for high-performance transistors, as anode material in lithium-ion batteries, and in conductive coatings and inks for printed circuit boards. These applications highlight the versatility and importance of carbon in the electronics industry.

- Q: What is methane?

- Methane is a colorless and odorless gas that is the primary component of natural gas. It is formed from the decay of organic matter and is a potent greenhouse gas.

- Q: How is carbon used in the production of steel?

- The production of steel heavily relies on carbon as it directly impacts the characteristics and properties of the end product. Carbon is primarily used as an alloying element in the steelmaking process, where it is carefully added to modify the composition of the steel. The basic oxygen furnace (BOF) process is one of the most commonly employed methods for steel production. In this process, carbon is introduced to the molten iron to achieve the desired grade of steel. The quantity of carbon added determines the steel's mechanical properties, including hardness and strength. Generally, higher levels of carbon result in a harder and stronger steel. Another steelmaking process, known as the electric arc furnace (EAF) process, also utilizes carbon. In this process, recycled steel scrap is melted down using an electric arc to create new steel. Carbon is added during this stage to adjust the carbon content to meet the requirements of the desired steel grade. Moreover, carbon plays a critical role in the heat treatment of steel. Through techniques like carburizing and quenching, carbon is utilized to enhance the surface hardness and wear resistance of steel components. This is particularly vital in industries such as automotive, aerospace, and construction, where the durability and strength of steel are of utmost importance. To summarize, carbon is indispensable in the production of steel as it directly influences the mechanical properties and overall quality of the final product. From regulating the carbon content to controlling heat treatment processes, carbon serves as an essential component in the steelmaking industry.

- Q: Carbon content of fly ash and fly ash roasted vector what is the relationship?

- The amount of burning loss of fly ash is the index that indicates the unburned organic matter in coal ash, including the number of carbon particles. The greater the burn loss, the more carbon is burnt. The presence of unburned carbon has a great negative impact on the quality of fly ash.

- Q: How does carbon impact ocean acidity?

- Carbon impacts ocean acidity through a process called ocean acidification. When carbon dioxide (CO2) from human activities is emitted into the atmosphere, a significant portion of it is absorbed by the ocean. Once in the ocean, CO2 reacts with water to form carbonic acid, which lowers the pH of seawater, making it more acidic. This increased acidity can have detrimental effects on marine life, particularly on shell-forming organisms like corals, mollusks, and some plankton, as it hampers their ability to build and maintain their calcium carbonate structures. Additionally, ocean acidification disrupts the delicate balance of marine ecosystems, affecting various species and ultimately impacting the entire food chain.

- Q: How does carbon impact the prevalence of floods?

- Carbon does not directly impact the prevalence of floods, but it does play a significant role in influencing climate change, which in turn can affect the occurrence and severity of floods. Carbon dioxide (CO2) is a greenhouse gas that is primarily responsible for trapping heat in the Earth's atmosphere, leading to a phenomenon known as global warming. This rise in global temperatures has several consequences, one of which is an increase in the frequency and intensity of extreme weather events, including floods. As the planet warms, the atmosphere is able to hold more moisture, resulting in an increased likelihood of heavy precipitation events. This can lead to more intense rainfall, causing rivers and other water bodies to overflow their banks and resulting in flooding. Additionally, warmer temperatures can also cause glaciers and ice caps to melt, contributing to rising sea levels, which can exacerbate the impacts of flood events, particularly in coastal regions. Furthermore, carbon emissions from human activities such as burning fossil fuels and deforestation are the primary drivers of climate change. By reducing our carbon footprint and transitioning to cleaner sources of energy, we can help mitigate the impacts of climate change and potentially reduce the prevalence of floods in the long term. It is important to note that while carbon emissions are a significant factor in climate change, they are not the sole cause of floods. Other natural factors such as rainfall patterns, topography, and land use also play important roles in determining flood risks.

- Q: How does carbon affect the electrical conductivity of materials?

- The electrical conductivity of materials can be significantly affected by carbon due to its unique electronic properties. Carbon atoms can form various allotropes, including graphite, diamond, and fullerenes, each having distinct electrical conductive properties. Take graphite, for example. It consists of carbon atoms arranged in a hexagonal lattice structure, forming strong covalent bonds within each layer. However, weak van der Waals forces exist between the layers, allowing electrons to move easily in the plane of the layers. This delocalization of electrons in graphite contributes to its high electrical conductivity, as the free electrons can move freely and carry electrical charges. On the other hand, diamond, another form of carbon, has a three-dimensional covalent network structure. Each carbon atom forms four strong covalent bonds with neighboring atoms, resulting in a highly rigid and stable lattice. The absence of free electrons in diamond restricts the movement of electrical charges, making it an insulator. The electrical conductivity of fullerenes, which are spherical carbon molecules, can vary depending on their structure. Some fullerenes can act as semiconductors, meaning their electrical conductivity can be controlled by introducing impurities or applying external stimuli. Furthermore, carbon can be used as a dopant in certain materials to enhance their electrical conductivity. For instance, adding small amounts of carbon to silicon can improve its electrical conductivity, making it suitable for electronic devices. In conclusion, carbon's impact on electrical conductivity relies heavily on its structure and arrangement within a material. Understanding the different forms and properties of carbon allows engineers and scientists to design materials with desired electrical conductive characteristics for various applications.

- Q: How does carbon impact the prevalence of heatwaves?

- Carbon impacts the prevalence of heatwaves by contributing to the greenhouse effect. When carbon dioxide and other greenhouse gases are released into the atmosphere, they trap heat from the sun, leading to a rise in global temperatures. This increase in temperature makes heatwaves more frequent, intense, and longer-lasting, posing significant risks to human health, ecosystems, and infrastructure.

- Q: How does carbon impact the quality of freshwater systems?

- Carbon can impact the quality of freshwater systems in various ways. Carbon dioxide (CO2) dissolved in water can lower its pH, leading to increased acidity and potentially harming aquatic organisms. Additionally, excessive carbon inputs from human activities like the burning of fossil fuels can contribute to eutrophication, causing algal blooms and depleting oxygen levels in water bodies, further compromising the health of freshwater ecosystems.

Send your message to us

Carbon Additve Carbon Raiser for Steel Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords