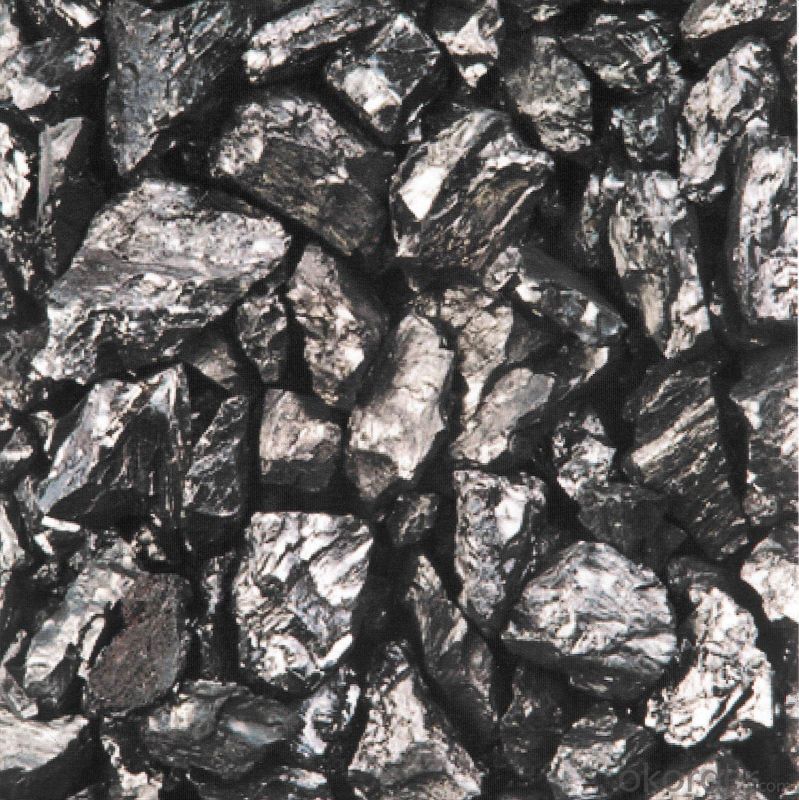

Carbon Additive Low Ash Low Sulphur Description

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications

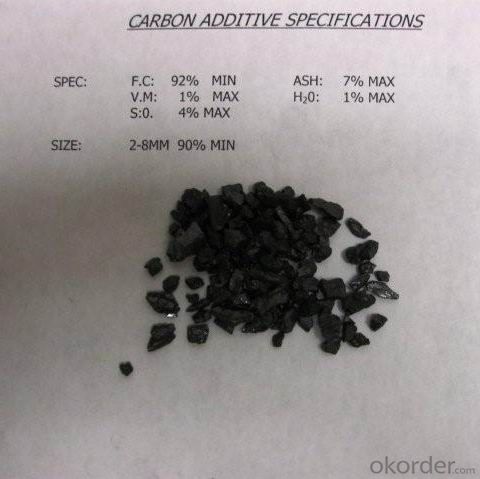

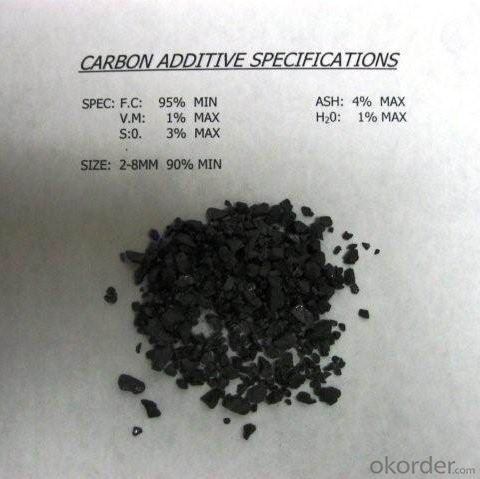

Carbon Additive Low Ash Low Sulfur Specifications

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Carbon Additive Low Ash Low Sulfur Specifications

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

..

Feature

Carbon Additive Low Ash Low Sulfur Specifications

| Specifications (%): | ||||||

| Grade | F.C | Ash | V.M | Moisture | S | Size |

| CR-95 | ≥95 | <4< td=""> | <1< td=""> | <1< td=""> | <0.3< td=""> | 0-30mm As buyer's request. |

| CR-94 | ≥94 | <4< td=""> | <1< td=""> | <1< td=""> | <0.3< td=""> | |

| CR-93 | ≥93 | <6< td=""> | <1< td=""> | <1< td=""> | <0.4< td=""> | |

| CR-92 | ≥92 | <7< td=""> | <1< td=""> | <1< td=""> | <0.4< td=""> | |

| CR-91 | ≥91 | <8< td=""> | <1< td=""> | <1< td=""> | <0.4< td=""> | |

| CR-90 | ≥90 | <8.5< td=""> | <1.5< td=""> | <2< td=""> | <0.4< td=""> | |

Image

Carbon Additive Low Ash Low Sulfur Specifications

FAQ:

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Carbon Additive Low Ash Low Sulfur Specifications

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: What are carbon credits?

- Carbon credits are a form of tradable permits that represent a reduction or removal of greenhouse gas emissions. They are used to incentivize and finance projects that aim to reduce carbon dioxide and other greenhouse gas emissions, contributing to the fight against climate change.

- Q: How does carbon impact the prevalence of tsunamis?

- Carbon does not directly impact the prevalence of tsunamis. Tsunamis are primarily caused by seismic activity, such as earthquakes or volcanic eruptions, which are unrelated to carbon emissions. However, rising carbon levels can contribute to global climate change, leading to the melting of polar ice caps and potentially increasing the risk of coastal flooding, which can indirectly amplify the impact of a tsunami.

- Q: Is graphite carbon?

- Chemically, it belongs to carbonWhen these carbon atoms connect with each other to form a single substance, they have different ways.

- Q: How does carbon affect water quality?

- Carbon can affect water quality by altering its pH level and reducing its oxygen content. Additionally, carbon can react with other chemicals present in water to form harmful compounds, compromising its overall quality and making it unsuitable for consumption and aquatic life.

- Q: What are the different types of carbon-based polymers?

- There are several different types of carbon-based polymers, each with its own unique properties and applications. Some of the most common types include: 1. Polyethylene (PE): This is one of the most widely used polymers and is known for its high strength and chemical resistance. It is commonly used in packaging materials, plastic bottles, and pipes. 2. Polypropylene (PP): PP is similar to PE but with a higher melting point and better resistance to heat. It is commonly used in automotive parts, textiles, and food packaging. 3. Polystyrene (PS): PS is a lightweight and rigid polymer that is commonly used in packaging materials, disposable utensils, and insulation. 4. Polyvinyl chloride (PVC): PVC is a versatile polymer that can be rigid or flexible depending on the additives used. It is commonly used in pipes, electrical insulation, and flooring. 5. Polyethylene terephthalate (PET): PET is a strong and lightweight polymer that is commonly used in beverage bottles, food containers, and synthetic fibers. 6. Polyurethane (PU): PU is a flexible and durable polymer that is commonly used in foams, coatings, adhesives, and textiles. 7. Polycarbonate (PC): PC is a strong and transparent polymer that is commonly used in eyeglass lenses, safety goggles, and electronic components. 8. Phenolic resins: These polymers are known for their excellent heat resistance and are commonly used in coatings, adhesives, and electrical components. These are just a few examples of the many carbon-based polymers that exist. Each type has its own specific properties and applications, making them suitable for a wide range of industries and products.

- Q: What are the industrial uses of diamonds?

- Due to their exceptional physical properties, diamonds have a wide range of industrial uses. One of the most common applications is in the manufacturing of cutting and grinding tools. Diamond-tipped saw blades, drill bits, and grinding wheels are highly sought after for their superior hardness and abrasion resistance. These tools are in high demand for cutting and shaping hard materials such as concrete, ceramics, and metals. In the electronics industry, diamonds are extensively utilized. They serve as heat sinks in high-power electronic devices and as abrasive materials for polishing and lapping electronic components. The thermal conductivity of diamonds allows them to efficiently dissipate heat, making them ideal for electronic devices that generate a significant amount of heat during operation. Moreover, diamonds play a crucial role in the production of specialized windows, lenses, and prisms used in various scientific and industrial applications. Their optical properties, including high refractive index and low dispersion, make them invaluable for creating precision optics employed in lasers, spectroscopy, and telecommunications. Additionally, diamonds have niche applications in the medical and dental fields. Their exceptional hardness and ability to retain sharp edges make them suitable for surgical tools like scalpels and dental drills. Diamond coatings are also applied to medical implants and prosthetics to enhance wear resistance and biocompatibility. Lastly, the oil and gas industry relies on diamonds for drilling and exploration purposes. Diamond drill bits are capable of penetrating extremely hard rock formations, making them essential for extracting oil and natural gas from deep beneath the Earth's surface. In summary, diamonds have vast and diverse industrial uses, ranging from cutting and grinding tools to electronics, optics, medicine, and even oil and gas exploration. The unique properties of diamonds make them indispensable in numerous industrial applications, contributing to advancements in various fields.

- Q: How does carbon impact the prevalence of avalanches?

- Carbon has a significant impact on the prevalence of avalanches. The increase in carbon emissions and subsequent global warming is leading to changes in snowpack stability, which in turn affects avalanche frequency and severity. As temperatures rise, snowfall patterns are becoming more unpredictable, with more frequent freeze-thaw cycles. This creates a weaker snowpack as the snow becomes less cohesive and more prone to sliding. Additionally, warmer temperatures cause more rain to fall instead of snow, further destabilizing the snowpack by adding weight and reducing its strength. These changes in snowpack stability increase the likelihood of avalanches occurring. Moreover, climate change also affects the timing and duration of snow accumulation. With warmer temperatures, snow melt occurs earlier, which can lead to a reduced snowpack during the peak avalanche season. This can result in a higher likelihood of triggering avalanches, as there may be a smaller buffer of stable snow to support the weight and stress of additional snowfall or human activity. Furthermore, carbon-induced climate change can alter the frequency and intensity of extreme weather events, such as heavy snowfalls or rainstorms. These events can cause rapid and significant changes in snowpack conditions, leading to an increased risk of avalanches. In summary, the impact of carbon on the prevalence of avalanches is significant. The warming climate affects snowpack stability, timing and duration of snow accumulation, and the frequency of extreme weather events, all of which contribute to an increased risk and prevalence of avalanches.

- Q: What are the impacts of carbon emissions on ecosystems?

- Carbon emissions have significant impacts on ecosystems. Increased levels of carbon dioxide in the atmosphere contribute to global warming, leading to changes in temperature and climate patterns. This can disrupt ecosystems by altering the timing of natural events, such as flower blooming or bird migration, and affecting the availability of resources like water and food. Additionally, carbon emissions can lead to ocean acidification, which harms marine life and coral reefs. Overall, carbon emissions pose a threat to the balance and functioning of ecosystems, ultimately impacting biodiversity and the health of our planet.

- Q: How is carbon used in the production of activated carbon filters?

- Activated carbon filters are widely used in various industries and applications, such as water and air purification, gas masks, and even in the production of certain chemicals. In the production of activated carbon filters, carbon plays a crucial role in their effectiveness. Activated carbon, also known as activated charcoal, is a highly porous form of carbon that has a large surface area. This porous structure is achieved through a process called activation, which involves heating carbonaceous materials, such as wood, coal, or coconut shells, at high temperatures in the presence of steam or certain chemicals. The activation process creates tiny pores and increases the surface area of the carbon, allowing it to effectively trap and remove impurities from gases or liquids. These impurities, including organic compounds, volatile organic compounds (VOCs), and certain heavy metals, are attracted to the surface of the activated carbon due to its high adsorption capacity. In the production of activated carbon filters, the activated carbon is typically formed into a granular or powdered form and then packed into a filter medium, such as a cartridge or a mesh. The filter medium acts as a support structure for the activated carbon, allowing the air or water to flow through while capturing and adsorbing the impurities. The activated carbon filters can effectively remove a wide range of contaminants, including chlorine, volatile organic compounds (VOCs), odors, and certain heavy metals. This makes them highly efficient in improving the quality of water and air by reducing pollutants and enhancing odor control. Moreover, the versatility of activated carbon allows for customization depending on the specific application. For example, activated carbon can be impregnated with certain chemicals to enhance its adsorption capacity for specific contaminants, or it can be specially treated to target certain pollutants, such as mercury or arsenic. In summary, carbon is used in the production of activated carbon filters due to its highly porous structure and excellent adsorption properties. These filters are crucial in various industries and applications, effectively removing impurities from water and air, improving their quality, and enhancing overall environmental and human health.

- Q: The victory of the lightning 3361 material is full of carbon fiber, and the 3363 is made of carbon fiber and resin, which is better??

- The two price is the same, 3363 is new, Dongdong should be the same (+ resin may be only.5%)

Send your message to us

Carbon Additive Low Ash Low Sulphur Description

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches