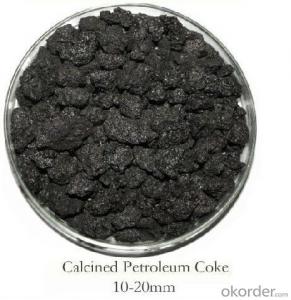

Carbon Additive FC 97 for casting iron and steel plant foundry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 300000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of carburant:

- Carburant for casting professional manufacturer in china 15 years experience;

- Carburant for casting specification as follows:

Item No (max) | Fixed Carbon | Sulfur(max) | Ash(max) | V.M | Moisture | Grain size(90%) | Nitrogen(max) |

CA-02 | 98.50% | 0.50% | 0.80% | 0.80% | 0.50% | 1-5MM | N/A |

CA-06 | 99.00% | 0.30% | 0.50% | 0.50% | 0.50% | 1-5MM | 1000divdivM |

CA-10 | 95.00% | 0.30% | 3.50% | 1.50% | 0.50% | 1-4MM | 700divdivM |

CA-12 | 80.00% | 0.10% | 16.50% | 3.50% | 2.00% | 1-5mm | N/A |

By using the carbon additive from CNBM in producing casting, it can increase the used quantity of Scrap steel and reduce the quantity of Scrap iron, or use no Scrap iron at all, CNBM carbon additive has follows properties: high absorptive character, no residue will be left, save production cost.

- Usage used to improve the Carbon content in steel-melting and Ductile iron foundry

- Characteristica high carbon, low sulfur, with stable effect for improving the carbon content, high absorptivity of carbon.

- Apply Used in electric furnace steel smelting and cast-iron for improving the carbon content

- Grain size normal size0.3-3mm 1-4mm1-3mm3-5mm,3-8mm,5-10mm or per as customers special requirement.

- Q: What are the potential uses of carbon nanomaterials in medicine?

- Carbon nanomaterials have immense potential in medicine due to their unique properties. They can be used for targeted drug delivery, imaging, tissue engineering, and diagnostics. Carbon nanotubes, for example, can transport drugs directly to cancer cells, reducing side effects. Additionally, carbon nanomaterials can provide high-resolution imaging of tissues and organs, aiding in early disease detection. Furthermore, they can be used to create scaffolds for tissue regeneration, promoting the growth of new cells and tissues. Overall, carbon nanomaterials hold great promise for revolutionizing medicine and improving patient outcomes.

- Q: How does carbon dioxide affect fuel efficiency?

- Fuel efficiency in vehicles is primarily influenced by factors such as engine efficiency, weight, aerodynamics, and driving conditions. Carbon dioxide, on the other hand, is a byproduct of burning fossil fuels, commonly used as vehicle fuel. When fossil fuels are burned, carbon dioxide is released into the atmosphere, contributing to the greenhouse effect and climate change. However, it is important to note that the increased concentration of carbon dioxide in the atmosphere does not directly impact fuel efficiency. Despite this, reducing carbon dioxide emissions remains crucial for mitigating climate change and promoting a sustainable future.

- Q: What are the impacts of carbon emissions on natural disasters?

- Natural disasters are significantly worsened by carbon emissions, leading to increased frequency and intensity. Carbon emissions have a major effect on global warming and climate change, as they cause the Earth's temperature to rise by trapping heat in the atmosphere. This temperature increase results in various weather pattern changes, which ultimately increase the occurrence and severity of natural disasters. One of the most evident consequences of carbon emissions on natural disasters is the stronger and more destructive hurricanes and tropical storms. These storms gain more energy from warmer ocean temperatures, making them more powerful. Additionally, higher temperatures lead to increased evaporation, resulting in heavier rainfall during storms and a higher risk of flooding and landslides. Carbon emissions also contribute to the melting of glaciers and polar ice caps, causing sea levels to rise. This rise in sea levels makes coastal areas more susceptible to storm surges and flooding during hurricanes and typhoons. Low-lying regions and island nations are particularly vulnerable, as they face the potential loss of their land due to rising waters. Moreover, carbon emissions play a role in the occurrence and severity of wildfires. Rising temperatures dry out vegetation, creating ideal conditions for wildfires to ignite and spread rapidly. These wildfires can devastate large areas of land, destroying ecosystems, homes, and livelihoods. Another consequence of carbon emissions on natural disasters is the disturbance of weather patterns. Climate change alters rainfall patterns, leading to longer and more severe droughts in some regions and more frequent and intense rainfall events in others. These changes in precipitation patterns can result in prolonged droughts, water scarcity, and a higher risk of wildfires in some areas, while others face increased flooding and landslides. In conclusion, carbon emissions have a profound impact on natural disasters. They contribute to global warming and climate change, intensify hurricanes, increase the risk of flooding, raise sea levels, fuel wildfires, and disrupt weather patterns. It is crucial to reduce carbon emissions and transition to clean and sustainable energy sources to mitigate these impacts and protect our planet from the devastating effects of natural disasters.

- Q: What is methane?

- Methane is a colorless and odorless gas that is the primary component of natural gas. It is the simplest hydrocarbon, consisting of one carbon atom and four hydrogen atoms, and has the chemical formula CH4. Methane is highly flammable and burns in the presence of oxygen, releasing carbon dioxide and water vapor. It is produced naturally through the decomposition of organic matter by bacteria in environments with little or no oxygen, such as swamps, marshes, and landfills. Methane is also produced by livestock, such as cows, as a byproduct of their digestive process. It is considered a greenhouse gas and a major contributor to climate change due to its ability to trap heat in the Earth's atmosphere. Methane is widely used as a fuel for heating and cooking, as well as in industrial processes and electricity generation.

- Q: What are the consequences of increased carbon emissions on social inequality?

- Increased carbon emissions have profound consequences on social inequality. The primary consequence is the exacerbation of existing inequalities, particularly in disadvantaged communities. Firstly, the effects of climate change, driven by carbon emissions, disproportionately impact marginalized communities, including low-income neighborhoods and developing countries. These communities often lack the resources and infrastructure necessary to withstand extreme weather events, such as hurricanes or flooding, resulting in greater vulnerability and loss of livelihoods. Secondly, the economic consequences of carbon emissions, such as rising energy costs and reduced agricultural productivity, further widen the gap between the rich and the poor. Affluent individuals may be able to adapt to these changes, while those with limited financial resources struggle to cope, leading to increased poverty and socio-economic disparities. Moreover, increased carbon emissions contribute to health disparities. Polluted air, resulting from carbon emissions, disproportionately affects low-income neighborhoods, where industrial plants and highways are often located. This leads to higher rates of respiratory diseases and other health issues among marginalized communities, exacerbating existing health inequalities. Furthermore, the impacts of climate change, driven by carbon emissions, can lead to forced displacement and migration. As environmental conditions deteriorate, communities may be forced to relocate, often resulting in social disruption and increased competition for resources. This can further marginalize vulnerable populations and create conflicts over land and access to resources. Lastly, the consequences of carbon emissions on social inequality extend globally. Developing countries, which contribute less to carbon emissions but bear a disproportionate burden of the impacts, face significant challenges in addressing climate change. Limited resources and technological capabilities hinder their ability to adapt and mitigate the effects, perpetuating global inequalities. In conclusion, increased carbon emissions have grave consequences on social inequality. They worsen existing disparities, particularly affecting marginalized communities, through the disproportionate impacts of climate change, economic hardships, health disparities, forced displacement, and global inequalities. Addressing carbon emissions and climate change is crucial not only for environmental sustainability but also for promoting social justice and reducing social inequality.

- Q: What are the effects of carbon emissions on the stability of mountains?

- Carbon emissions have a range of adverse effects on the stability of mountains. Increased carbon dioxide levels in the atmosphere contribute to global warming, leading to the melting of glaciers and permafrost in mountainous regions. This thawing destabilizes the slopes, resulting in an increased risk of landslides, rockfalls, and avalanches. Additionally, climate change caused by carbon emissions alters precipitation patterns, leading to more intense rainfall events and the potential for erosion and soil instability in mountainous areas. These combined effects pose significant threats to the stability and long-term sustainability of mountain ecosystems.

- Q: What are the advantages of carbon nanotube transistors?

- Carbon nanotube transistors have several advantages over traditional silicon-based transistors. Firstly, carbon nanotubes have a much smaller size, allowing for the creation of highly compact and powerful electronic devices. Their high current-carrying capacity also enables faster and more efficient signal processing. Additionally, carbon nanotubes possess excellent electrical properties, such as high mobility and low resistance, resulting in reduced power consumption and improved device performance. Moreover, they exhibit exceptional thermal conductivity, ensuring better heat dissipation and overall device reliability. Lastly, carbon nanotubes are highly flexible and can be integrated into various substrates, enabling the development of flexible and wearable electronics.

- Q: What is carbon neutral energy?

- Energy sources that do not release carbon dioxide (CO2) into the atmosphere when used are known as carbon neutral energy. The concept aims to minimize the negative impact of energy production on the environment and climate change. Achieving carbon neutral energy is possible through various methods, including the use of renewable energy sources like solar, wind, hydro, and geothermal power. These sources do not emit CO2 during operation. Carbon neutral energy can also be obtained by combining fossil fuels with carbon capture and storage (CCS) technologies. This process involves capturing and storing the CO2 emitted during combustion underground, preventing it from entering the atmosphere. The objective of carbon neutral energy is to reduce greenhouse gas emissions and mitigate the effects of climate change, making it an essential step towards a sustainable and cleaner future.

- Q: Made of high strength structural partsThe market quality of the carbon fiber plate is too much, the price is low, do not know how to choose. A knowledgeable friend can introduce larger enterprises? The quality of the carbon fiber board produced must be better and the performance should be stable!

- You are not for the prestressing bar, if you find the building reinforcement for Tianjin Beijing card, if you do the structure reinforcement for Jiangsu and Wuxi via the new material industry, these are relatively well-known.

- Q: I want to make a rectangular round bar for bearing. What carbon fiber and carbon fiber should be used? How should I do it? What kind of machine does it use to dry it?

- Carbon fiber is not plastic, and plastic is not the same material. Carbon fiber forming process is mainly:A molding process is: by hand will prepreg paper in the mold, and then curing. This is the biggest advantage of simple manufacturing process, manual to complete more complex operations, can process the complex shape parts, suitable for small batch production; the disadvantage is low efficiency and poor labor conditions, labor intensity is big.Filament winding forming technology: the earliest continuous forming process, that is, the fiber is dipped into the resin through the resin trough, and then wrapped on the rotating core mold according to certain rules. Then, the glue is solidified and formed by heating. A prominent feature is that it is in accordance with the stress situation of products, the fiber according to a certain rule arrangement, so as to give full play to the strength of the fiber, obtain the lightweight products; can realize continuous and mechanized production in the process, and short production cycle, high production efficiency, low labor intensity, suitable for manufacturing cylinder the sphere, and some positive curvature gyration bodies or tubular products.

Send your message to us

Carbon Additive FC 97 for casting iron and steel plant foundry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 300000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords