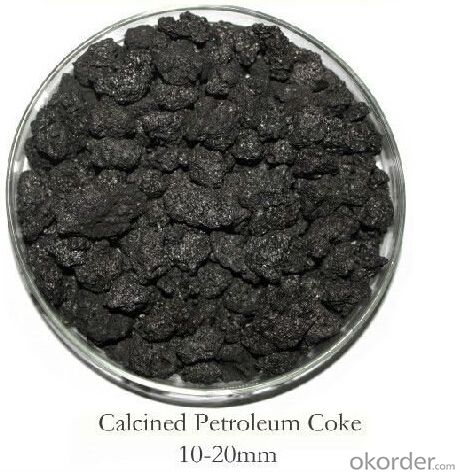

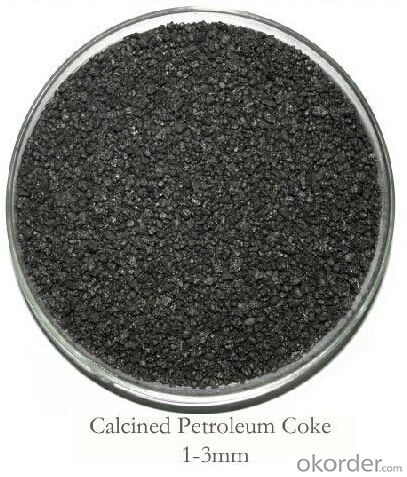

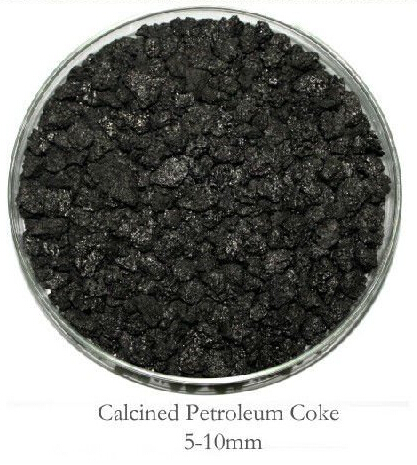

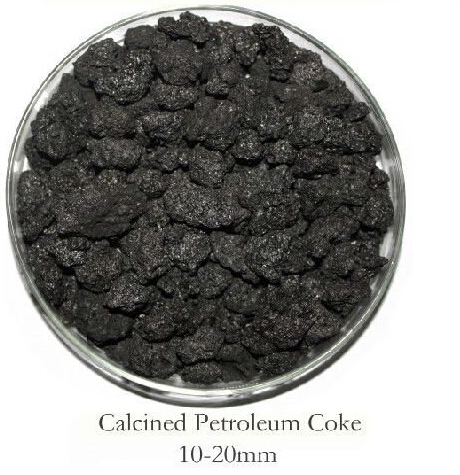

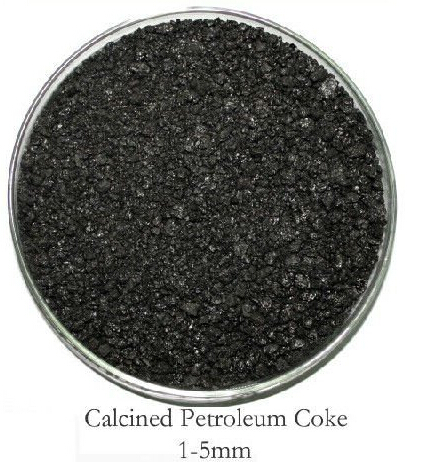

Carbon Additive High FC 10-20mm for Casting Iron Foundry And Steel Plant

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 500000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Calcined Petroleum Coke:

Calcined Petroleum Coke comes from delayed coke which extracted from oil refinery. Although Calcined Petroleum Coke contains a little bit higher level of sulfur and nitrogen than pitch coke, the price advantage still makes it widely used during steel-making and founding as a kind of carbon additive/carburant

petroleum coke price is lower than graphite pet coke. It is widely used by most foundry plants.

Our product has follwing advantages:

The morphology, chemistry and crystallinity of recarburizer have a major impact on the overall casting cost. The combined application and cost benefits, enable foundries to manufacture castings in a highly cost effective manner.

Reduces:

- Recarburiser consumption

- Power consumption

- Inoculant consumption

- MgFeSi consumption

- Furnace refractory wear

- Scrap rate

- Tap to tap time

- Slag inclusions risk

- Chill

Increases:

- Casting microstructure

- Productivity

- Process consistency

Carbon Recovery:

Compared with calcined petroleum coke, acetylene coke and

graphite electrode scrap, our yields the highest carbon

recovery and fastest dissolution time

- Q: Is carbon a conductor?

- It depends on what kind of material, the cartridge is the conductor, and the coal is not the conductor

- Q: What is the carbon emission of the air conditioner?

- Air conditioner using electric energy, itself is not the direct carbon emissions, but due to power consumption, power is not the primary energy, is two times the energy, so the power will come from where it is not decided or no pollution low and zero carbon emissions.Like water power, wind energy and solar energy, clean energy generates electricity without carbon emissions. It is pollution-free and zero carbon emissions. The use of coal raw materials power generation plants have carbon emissions, so air-conditioning carbon emissions is not easy to say, it depends on the specific circumstances analysis and decision.

- Q: What are the consequences of increased carbon emissions on forest ecosystems?

- Forest ecosystems experience significant consequences due to the increase in carbon emissions. One of the most notable effects is the modification of climate and weather patterns. The excessive presence of carbon dioxide in the atmosphere results in the retention of heat, leading to global warming. This rise in temperature can disrupt the delicate equilibrium of forest ecosystems. The warmer temperatures can cause shifts in the distribution and composition of tree species, as some may struggle to adapt to the changing conditions. Another outcome of the rise in carbon emissions is the acidification of rainwater. When carbon dioxide combines with water vapor, it creates carbonic acid, which can fall as acid rain. Acid rain has detrimental impacts on forest ecosystems, as it extracts vital nutrients from the soil and damages tree leaves and other vegetation. This weakens the overall health of the forest and makes it more susceptible to diseases and pests. Moreover, increased carbon emissions contribute to the intensification of wildfires. Higher temperatures and drier conditions provide an ideal environment for fires to spread and occur more frequently. Forests that have evolved to withstand natural fire patterns may struggle to cope with the increased intensity and frequency of these fires. This can result in the loss of biodiversity, destruction of habitat, and long-term degradation of forest ecosystems. Lastly, increased carbon emissions contribute to the phenomenon known as ocean acidification, where excess carbon dioxide is absorbed by the oceans. This acidification can impact the well-being of coastal and marine ecosystems, which are intricately connected to forest ecosystems. Many forest ecosystems, such as mangroves and salt marshes, serve as important nursery habitats for marine species. If these forest ecosystems decline due to carbon emissions, it can have cascading effects on the health and productivity of coastal and marine ecosystems. Overall, the increase in carbon emissions has wide-ranging consequences on forest ecosystems. It alters climate patterns, causes acid rain, intensifies wildfires, and affects coastal and marine ecosystems. These impacts not only harm the trees and vegetation within the forests but also disrupt the delicate balance of the entire ecosystem, resulting in the loss of biodiversity and long-term degradation. It is crucial to mitigate carbon emissions and promote sustainable practices to minimize these consequences and preserve the health and integrity of forest ecosystems.

- Q: How does carbon dioxide contribute to global warming?

- Carbon dioxide (CO2) contributes to global warming primarily through the greenhouse effect. This effect occurs when certain gases in the Earth's atmosphere trap heat from the sun, preventing it from escaping back into space. While the greenhouse effect is a natural process that helps maintain the Earth's temperature, human activities, such as the burning of fossil fuels, have significantly increased the concentration of CO2 in the atmosphere. When fossil fuels like coal, oil, and natural gas are burned for energy production, CO2 is released into the atmosphere as a byproduct. This excess CO2 acts as a heat-trapping gas, absorbing and re-emitting heat radiation that would otherwise escape into space. As a result, the Earth's temperature is increasing, leading to global warming. The increase in global temperatures has far-reaching consequences. It accelerates the melting of polar ice caps and glaciers, causing rising sea levels that threaten coastal areas and low-lying islands. It also disrupts weather patterns, leading to more frequent and severe heatwaves, droughts, and extreme weather events like hurricanes and floods. Moreover, global warming affects ecosystems, causing shifts in habitats, loss of biodiversity, and detrimental impacts on plant and animal species. The importance of reducing carbon dioxide emissions is crucial to mitigating global warming. This can be achieved through various means, including transitioning to renewable energy sources, improving energy efficiency, investing in sustainable transportation, and adopting practices that promote reforestation and carbon sequestration. By taking these actions, we can slow down the rate of global warming and mitigate its adverse effects on the planet and its inhabitants.

- Q: What are the consequences of increased carbon emissions on tourism industry?

- The tourism industry is greatly affected by the significant consequences of increased carbon emissions. One prominent result is the deterioration of natural landscapes and ecosystems that attract tourists. Carbon emissions contribute to global warming, which leads to higher temperatures, melting glaciers, and more frequent extreme weather events like hurricanes and droughts. These environmental changes can cause the destruction of iconic landmarks, such as coral reefs or national parks, which are often the main attractions for tourists. Additionally, increased carbon emissions contribute to air pollution, which can have negative effects on air quality in popular tourist destinations. This poor air quality can lead to respiratory problems and other health issues for both tourists and local populations, making these places less desirable to visit. Moreover, the degradation of natural environments due to carbon emissions can also harm wildlife, resulting in a decline in biodiversity. This loss of wildlife can reduce the appeal of ecotourism destinations, which heavily rely on diverse flora and fauna. Furthermore, the tourism industry heavily depends on transportation, which is a major source of carbon emissions. The use of fossil fuels in planes, ships, and cars contributes to the industry's overall carbon footprint. As countries strive to decrease their carbon emissions, they may enforce stricter regulations or impose taxes on air travel, making it more expensive and less accessible for travelers. This can impact the number of tourists visiting different destinations and impede the growth of the tourism industry. Lastly, the consequences of increased carbon emissions extend beyond environmental factors. Climate change and extreme weather events can disrupt travel plans, resulting in cancellations and financial losses for both tourists and businesses in the tourism industry. Additionally, destinations that heavily rely on winter tourism, like ski resorts, may face challenges due to shorter snow seasons or inconsistent snowfall patterns caused by climate change. In conclusion, increased carbon emissions have dire consequences on the tourism industry. From the degradation of natural landscapes and ecosystems to the impact on air quality and wildlife, the effects of carbon emissions can discourage tourists from visiting certain destinations. Furthermore, the industry's reliance on transportation contributes to its overall carbon footprint, potentially leading to increased costs and limited accessibility for travelers. Climate change-related disruptions and financial losses further exacerbate the challenges faced by the tourism industry.

- Q: What are the carbon monoxide collection methods?

- Drainage methodExhaust air cannot be used because CO is poisonous

- Q: How do humans contribute to carbon emissions?

- There are several ways in which humans contribute to carbon emissions. One significant source of carbon emissions arises from the burning of fossil fuels for electricity, transportation, and heating purposes. This involves the combustion of coal, oil, and natural gas, resulting in the release of carbon dioxide (CO2) into the atmosphere. The use of these fossil fuels is widespread in our everyday lives, from powering our homes and vehicles to manufacturing goods and producing food. Furthermore, deforestation, which is primarily caused by human activities such as agriculture, logging, and urbanization, also adds to carbon emissions. Trees absorb CO2 and release oxygen, so when they are cut down, the stored carbon is released back into the atmosphere. Additionally, industrial processes like cement production and chemical manufacturing also emit significant quantities of CO2. Lastly, the livestock industry, particularly the production of beef and dairy products, contributes to carbon emissions through the release of methane from livestock and the deforestation required to expand grazing areas and cultivate animal feed. In conclusion, human activities directly and indirectly contribute to carbon emissions, underscoring the necessity for collective efforts to mitigate and reduce our environmental impact.

- Q: What is carbon nanophotonics?

- Carbon nanophotonics is a branch of science and technology that focuses on the study and manipulation of light at the nanoscale using carbon-based materials. It involves the integration of carbon-based nanomaterials, such as carbon nanotubes, graphene, and diamond nanoparticles, with photonics to enable the development of novel optical devices and systems. The unique properties of carbon-based nanomaterials, such as their exceptional electrical conductivity, high mechanical strength, and excellent optical properties, make them ideal candidates for applications in nanophotonics. These materials have the ability to confine and manipulate light at the nanoscale, allowing for the miniaturization of optical components and the realization of enhanced light-matter interactions. Carbon nanophotonics has a wide range of potential applications across various fields. One prominent area is in telecommunications, where carbon nanomaterials can be used to develop high-speed and compact photonic devices for data transmission. Additionally, carbon nanophotonics has the potential to revolutionize the field of sensing by enabling the development of highly sensitive and selective sensors for detecting various molecules and substances. It also holds promise in the field of energy harvesting, where carbon nanomaterials can be utilized to enhance the efficiency of solar cells and other photovoltaic devices. Overall, carbon nanophotonics represents an exciting and rapidly evolving field that combines the unique properties of carbon-based nanomaterials with the principles of photonics to create innovative optical technologies. By harnessing the power of light at the nanoscale, carbon nanophotonics has the potential to revolutionize various industries and pave the way for new advancements in science and technology.

- Q: What are the advantages of carbon-based fuel cells?

- There are several advantages of carbon-based fuel cells. Firstly, carbon-based fuel cells, such as those using hydrogen or methanol, have a high energy density, allowing for longer operating times and greater efficiency. Secondly, carbon-based fuel cells are environmentally friendly as they produce fewer emissions compared to traditional fossil fuel combustion. Additionally, carbon-based fuel cells are versatile and can be used in a variety of applications, from powering vehicles to providing electricity for homes and businesses. Finally, carbon-based fuel cells offer a promising alternative to traditional energy sources, reducing our dependence on finite resources and contributing to a more sustainable future.

- Q: What is the importance of carbon dating in archaeology?

- Carbon dating is crucial in archaeology as it allows us to determine the age of artifacts and remains with remarkable accuracy. By analyzing the levels of carbon-14 isotopes in organic materials, we can establish when they were last alive or in use. This information provides valuable insights into the chronology of human history, enabling archaeologists to reconstruct past civilizations, understand cultural changes, and refine our understanding of the past.

Send your message to us

Carbon Additive High FC 10-20mm for Casting Iron Foundry And Steel Plant

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 500000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords