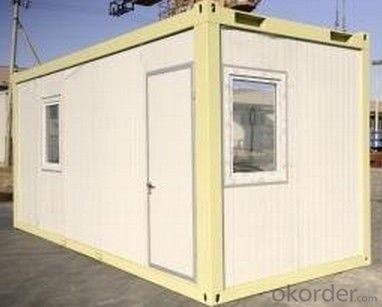

Mark & model : The product is featured as frame structure and prefabricated insulation, elegant appearance harmonizes with scenic spot, free assembly and combination, integrated decoration, complete indoor supporting facilities, being suitable for locations short of convenient facilities.

Origin : Asia and Pacific Area China

Quality standard : International

Submit date : 2013-09-23

H.S.Classification : Furniture & Toys Furniture 9406 Prefabricated buildings

Product profile : Campsite Container-type House

Size: 2435(W)mm×6055(L)mm×2790(H)mm

Notes of Product:

1.Customized dwelling conditions, heat insulating, sealed and strong soundproof performance, much more comfortable than common temporary building.

2.The product is featured as excellent fireproof performance, the heat insulating material adopts incombustible material.

3.Highly integrated, no need of foundation on site or secondary decoration, dwellers can move in at once when it is hoisted and installed.

4.Modular assembly, free combination breadthways or lengthways.

5.The indoor room expands greatly to build super-large space.

6.It is easy to move and hoist and could be reused.

Quality Standard: Industrial standard

Origin: China

Commodity Classification: Exported site container house (high-end)

Descriptions:

1.Customized dwelling conditions, heat insulating, sealed and strong soundproof performance, much more comfortable than common temporary building.

2.The product is featured as excellent fireproof performance, the heat insulating material adopts incombustible material.

3.Highly integrated, no need of foundation on site or secondary decoration, dwellers can move in at once when it is hoisted and installed.

4.Modular assembly, free combination breadthways or lengthways.

5.The indoor room expands greatly to build super-large space.

6.It is easy to move and hoist and could be reused.

Features:

1.The product is featured as frame structure and prefabricated insulation.

2.Elegant appearance harmonizes with scenic spot.

3.Free assembly and multi-floor combination in different directions.

4.Integrated decoration and complete indoor supporting facilities.

Applications:

Business: Office room, office building, business building.

Residential: Hotel, apartment, dormitory, traveling campsite, public-rent house.

Commercial: Supermarket, convenient store, noshery, farmer’s house, cabinet, sales center, reception center.

Education: School, training base.

Campsite: Temporary building for field exploration and construction site of such industries as oil gas field, industrial mining, road building, railway, bridge and so on.

Disaster Relief: Government relocation of victims, military barracks.

Public Events: Public building and construction for public events including sports meeting and exhibition.

Functional House: Kitchen, dining hall, bathroom, gym, clinic, laundry house, equipment room, storage room and so on.