Calcined Anthracite Coal Recarburizer for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

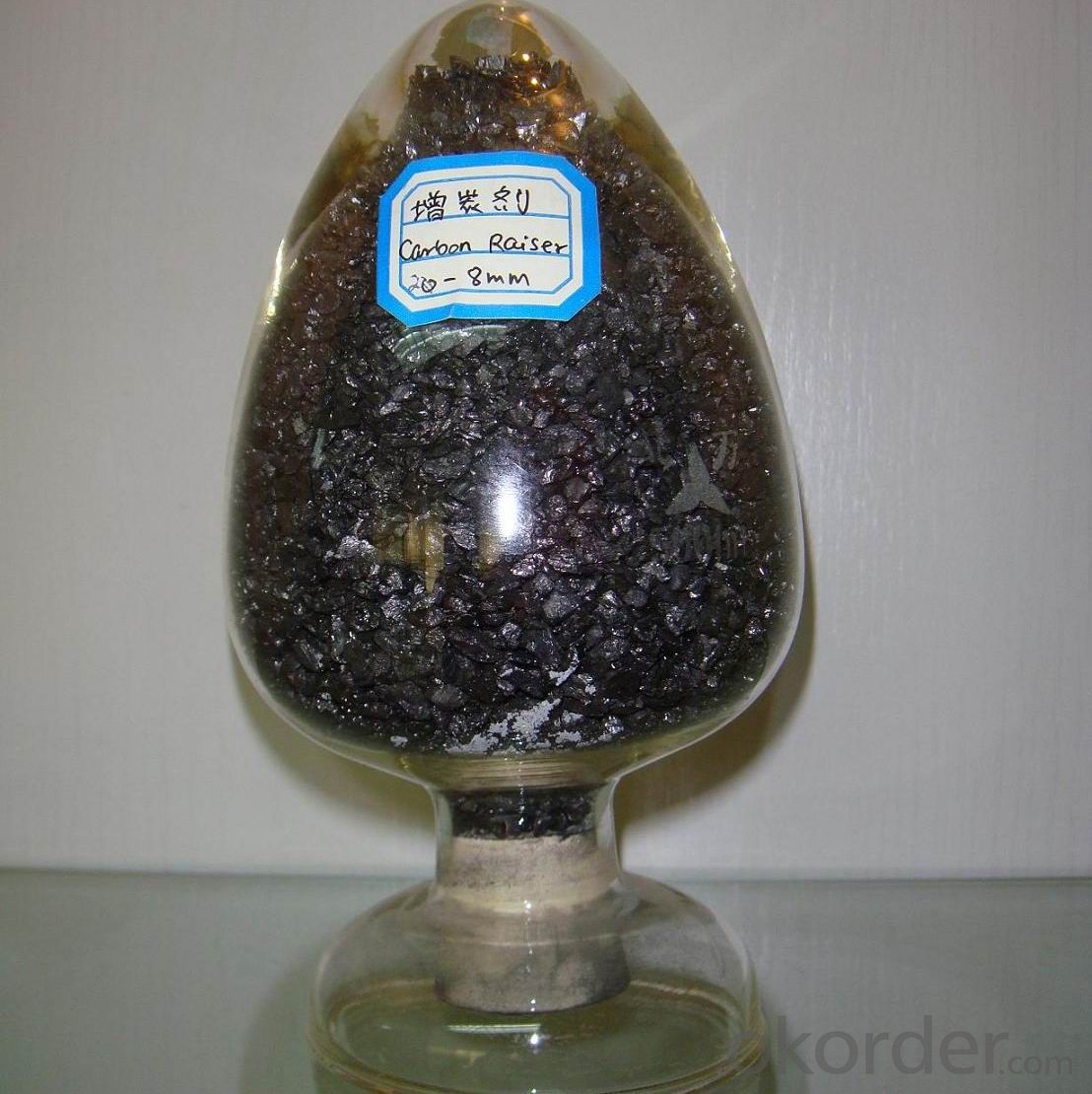

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications

Carbon Additve Low Sulphur for Steelmaking

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Carbon Additve Low Sulphur for Steelmaking

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Feature

Carbon Additve Low Sulphur for Steelmaking

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4 | <1 | <1 | <0.3 | 0-30mm |

CR-94 | ≥94 | <4 | <1 | <1 | <0.3 | |

CR-93 | ≥93 | <6 | <1 | <1 | <0.4 | |

CR-92 | ≥92 | <7 | <1 | <1 | <0.4 | |

CR-91 | ≥91 | <8 | <1 | <1 | <0.4 | |

CR-90 | ≥90 | <8.5 | <1.5 | <2 | <0.4 | |

Image

Carbon Additve Low Sulphur for Steelmaking

FAQ:

Carbon Additve Low Sulphur for Steelmaking

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Carbon Additve Low Sulphur for Steelmaking

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: There is a graphite mine, looking for three experts engaged in mineral processing industry asked. They say earthy graphite, and the answer to the taste is quite different. Some say that the fixed carbon content of 15, and some say graphite grade 90%. The same sample. Some people say that very valuable, and some say that the grade is too low, worthless. I'm all confused. What do you mean by graphite grade and fixed carbon?

- The taste of graphite powder refers to its purity, that is, the amount of carbon; fixed carbon content refers to the removal of water, ash and volatile residues, it is an important indicator of the use of coal. The two are essentially different

- Q: What is the density of carbon steel and alloy steel?

- Chromium molybdenum aluminum steel 7.65Tungsten 9 high speed tool steel 8.3Tungsten 18 high speed tool steel 8.7High strength alloy steel 7.82Bearing steel 7.81Stainless steel 0Cr13, 1Cr13, 2Cr13, 3Cr13, 4Cr13, Cr17Ni2, Cr18, 9Cr18, Cr25,, Cr28 7.75Cr14, Cr17 7.70Cr18Ni9, 1Cr18Ni9, Cr18Ni9Ti, 2Cr18Ni9 7.851Cr18Ni11Si4A1Ti 7.52Stainless steel 1Crl8NillNb, Cr23Ni18 7.92Cr13Ni4Mn9 8.53Cr13Ni7Si2 8

- Q: How does carbon dioxide affect global warming?

- Carbon dioxide (CO2) is a greenhouse gas that plays a significant role in global warming. When released into the atmosphere, CO2 traps heat from the sun, preventing it from escaping back into space. This process leads to the Earth's temperature increasing, resulting in global warming. The increased levels of CO2, primarily from human activities such as burning fossil fuels, deforestation, and industrial processes, have caused a substantial rise in the Earth's average temperature over the past century. This rise in temperature has led to various adverse effects, including melting ice caps, sea-level rise, extreme weather events, and disruptions to ecosystems. Thus, carbon dioxide is a major contributor to global warming and its associated impacts.

- Q: How about carbon content of coal ash?

- Ash, carbon content, ash, carbon content, ash, carbon content, ash, carbon content, determination, determination, determination, determination (determination, determination)1 sampling(1) in the different positions of the ash, 7-10 points are deep to collect ash and 2-3kg. When sampling, not intentionally pick or avoid channels of ash, namely as ash samples taken, regardless of its size, regardless of the depth of color, regardless of its hardness, as far as possible to obtain a fully representative sample.(2) slag made on thick steel plate clean, which is smashed big gray block, mixing evenly into a cone, flattened, with a shovel cut ten sub center line, which is divided into 4 parts, two samples of diagonal, the other half abandoned.(3) repeat (2) operation. Reduce the amount to several times, until the ash is reduced to about 50 grams. Bring the ash back to the laboratory. The abandoned ash is discharged back into the ash heap.2, sample preparation(1) the ash in the laboratory will be retrieved and dried in a heated air drying oven (about 1 hours) at 105-110 degrees centigrade.(2) crushing the dry ashes with the disc vibrating mill, and the fine ash powder is the analysis sample.

- Q: What should be done to deal with leakage of carbon monoxide from the plant?

- The hazardous and dangerous characteristics of carbon monoxide, carbon monoxide, is the Chinese name of CO. It is the product of incomplete combustion of materials. It is slightly soluble in water and soluble in various organic solvents such as ethanol and benzene. Mainly used in industrial chemical synthesis, such as synthetic methanol, phosgene, etc., or refined metal reducer. Occupation exposure to carbon monoxide in manufacturing steel and iron, coke, ammonia, methanol, graphite electrode, printing and dyeing factory, singeing, internal combustion engine powered coal mining blasting; non occupation contact is more extensive, such as household water heater was boiling water, winter coal, gas heating and so on, will produce carbon monoxide. Carbon monoxide is a flammable toxic gas known, but because of its physical and chemical properties of colorless smelly, so it is not easy to be aware of the harm, so it is not only the occupation killer, or the people's daily living potential. Carbon monoxide mixed with air can form an explosive mixture. When exposed to fire, high heat can cause combustion and explosion. Bottled carbon monoxide in case of high fever, increased pressure within the container, cracking and explosion. Because carbon monoxide has flammable properties, strong oxidizing agents and alkalis are its inhibitions. If the fire, should immediately cut off the gas source; if not immediately cut off the gas source, is not allowed to extinguish the burning gas.

- Q: How does carbon affect the quality of drinking water?

- Carbon can affect the quality of drinking water through two main mechanisms: activated carbon filtration and carbon dioxide (CO2) absorption. Activated carbon filtration is commonly used in water treatment processes to remove organic contaminants, chemicals, and odors, improving the taste and odor of drinking water. On the other hand, excessive dissolved carbon dioxide in water can make it acidic and affect the pH level, potentially making it corrosive and altering the taste. However, carbon itself is not harmful to human health and can be beneficial in certain forms, such as in the form of activated carbon filters.

- Q: How does carbon affect air quality?

- Air quality can be affected both positively and negatively by carbon. On the one hand, carbon dioxide (CO2) is a natural part of the Earth's atmosphere and vital for plant survival and photosynthesis. Nevertheless, an excess of CO2 can contribute to the greenhouse effect, resulting in global warming and climate change. Furthermore, carbon monoxide (CO), a harmful pollutant produced during incomplete combustion, can have a detrimental impact on air quality. It is primarily released by vehicles, industrial processes, and residential heating systems. Elevated levels of carbon monoxide can impede the body's oxygen delivery, causing various health problems such as headaches, dizziness, and in severe cases, even death. Additionally, compounds containing carbon, like volatile organic compounds (VOCs), can play a role in the creation of ground-level ozone, which is a harmful pollutant. Ground-level ozone can lead to respiratory issues, worsen existing respiratory conditions, and reduce lung function. VOCs are emitted by different sources, including vehicle emissions, industrial processes, and specific household products. In conclusion, while carbon dioxide is crucial for life on Earth, excessive amounts can contribute to climate change. Conversely, carbon monoxide and volatile organic compounds released by human activities can have adverse effects on air quality and human health. Therefore, it is crucial to decrease carbon emissions and adopt cleaner technologies to mitigate the negative impacts of carbon on air quality.

- Q: How does carbon impact the stability of savannah ecosystems?

- Carbon plays a crucial role in the stability of savannah ecosystems. It is an essential element for all living organisms and is involved in various ecological processes. Carbon is primarily present in the form of organic matter, which is vital for the growth and development of plants, the primary producers in these ecosystems. In savannahs, carbon impacts stability in multiple ways. Firstly, carbon dioxide (CO2) is a key component of the Earth's atmosphere and plays a significant role in regulating the global climate. Savannas are known for their ability to sequester and store large amounts of carbon in their vegetation and soils. This carbon storage helps mitigate climate change by reducing the amount of CO2 in the atmosphere. Furthermore, carbon is essential for plant growth through photosynthesis. Savanna plants, such as grasses and scattered trees, utilize carbon dioxide from the air, converting it into carbohydrates and other organic compounds. This process not only provides plants with energy but also contributes to the overall productivity of the ecosystem. The stability of savannah ecosystems also depends on the interaction between plants and animals. Carbon-rich vegetation serves as a food source for herbivores, such as zebras and antelopes, which in turn support predators like lions and hyenas. The carbon cycle ensures a continuous flow of energy and nutrients throughout the food web, maintaining the balance and stability of the ecosystem. Moreover, the carbon content in savannah soils influences their fertility and ability to retain moisture. Organic matter, derived from decaying plant material, improves soil structure, nutrient availability, and water holding capacity. This, in turn, supports the growth of vegetation and sustains the diverse array of species found in savannah ecosystems. However, human activities, such as deforestation, agricultural practices, and the burning of fossil fuels, are altering the carbon balance in savannahs. Deforestation removes carbon-rich trees and plants, reducing the overall carbon storage capacity of the ecosystem. Additionally, the release of carbon dioxide from the burning of fossil fuels contributes to the greenhouse effect and climate change, which can disrupt the stability of savannah ecosystems. In conclusion, carbon plays a critical role in maintaining the stability of savannah ecosystems. It influences climate regulation, supports plant growth, provides energy for the food web, and enhances soil fertility. However, human activities that disrupt the carbon balance in these ecosystems can have detrimental effects on their stability and overall health. Therefore, efforts to conserve and restore savannah ecosystems are essential for preserving their carbon storage capacity and ensuring their long-term stability.

- Q: Does iron have more carbon or more steel?

- Iron has a high carbon contentThe main difference is that the pig iron, wrought iron and steel carbon content, carbon content of more than 2% of iron is iron; carbon content of less than 0.04% of the iron, the carbon content in the name of wrought iron; 0.05~2% iron, known as steel.

- Q: What is the structure of graphite, another form of carbon?

- Graphite has a layered structure where carbon atoms are arranged in hexagonal rings, forming sheets of interconnected hexagons. These sheets are stacked on top of each other, with weak forces of attraction between them, resulting in a slippery and flaky structure.

Send your message to us

Calcined Anthracite Coal Recarburizer for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords