Calcined Anthracite Coal Carbon Coke for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

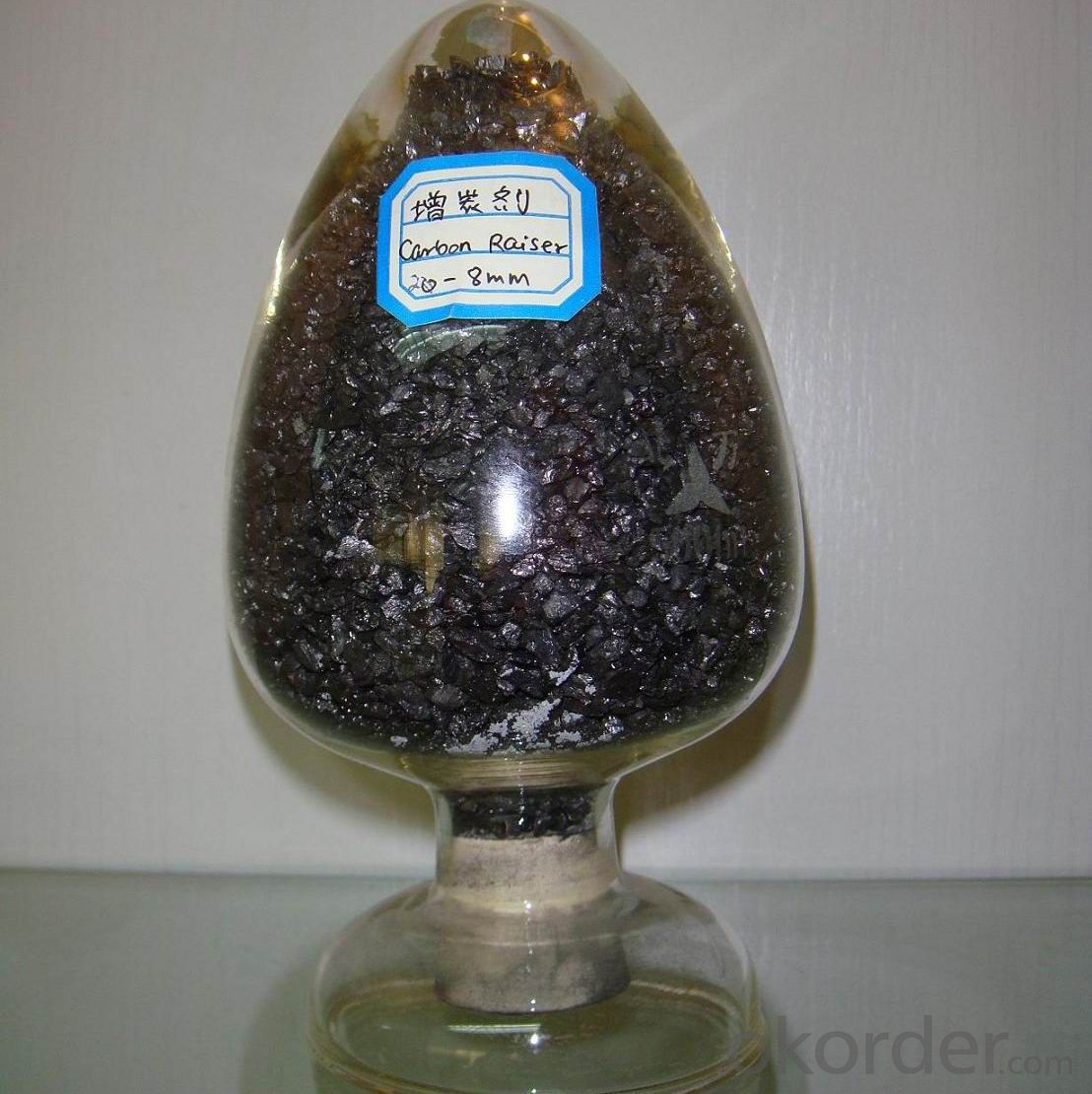

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

Packaging Details: | In 1MT plastic woven bag. |

Delivery Detail: | 30-40 DAYS |

Calcined Anthracite Coal Carbon Coke for Steelmaking

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Features of Calcined Anthracite Coal Carbon Coke for Steelmaking

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

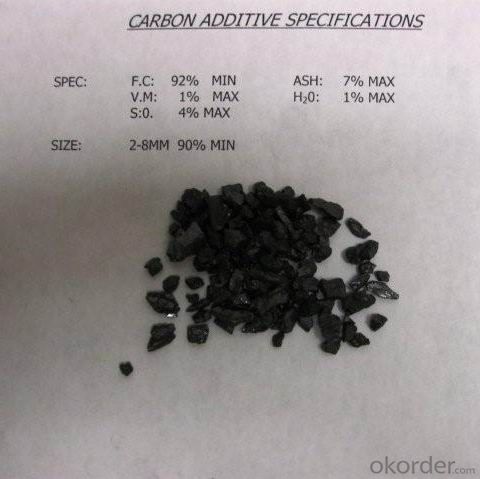

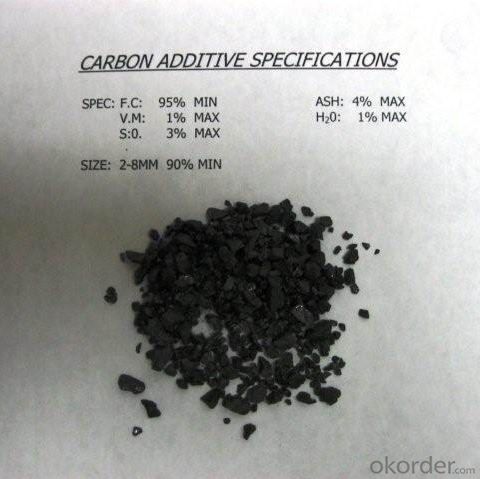

Specifications of Calcined Anthracite Coal Carbon Coke for Steelmaking

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4 | <1 | <1 | <0.3 | 0-30mm |

CR-94 | ≥94 | <4 | <1 | <1 | <0.3 | |

CR-93 | ≥93 | <6 | <1 | <1 | <0.4 | |

CR-92 | ≥92 | <7 | <1 | <1 | <0.4 | |

CR-91 | ≥91 | <8 | <1 | <1 | <0.4 | |

CR-90 | ≥90 | <8.5 | <1.5 | <2 | <0.4 | |

FAQ of Calcined Anthracite Coal Carbon Coke for Steelmaking

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is:instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage of Calcined Anthracite Coal Carbon Coke for Steelmaking

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

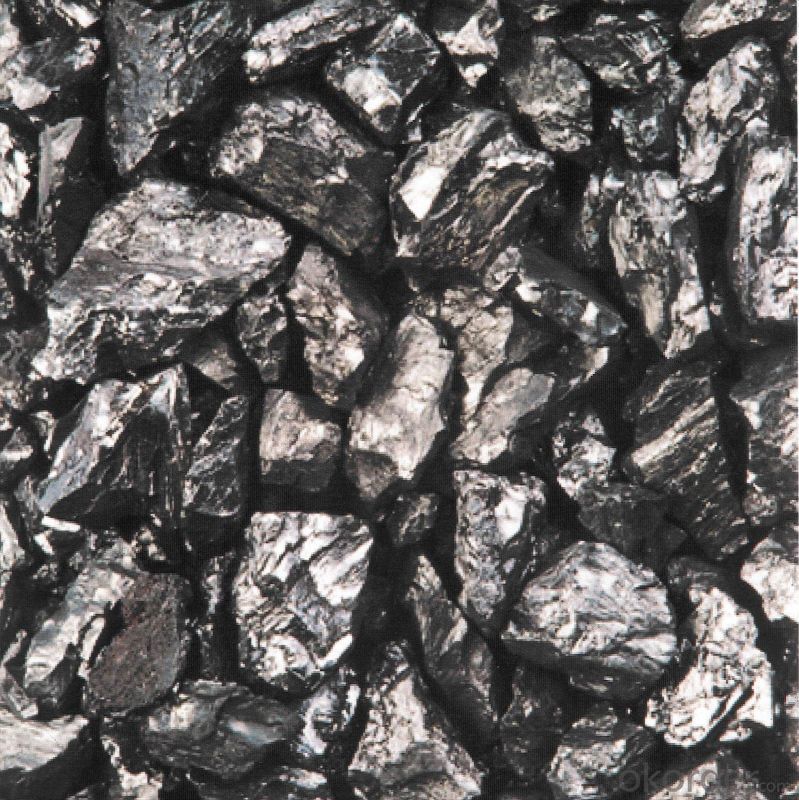

Images of Calcined Anthracite Coal Carbon Coke for Steelmaking

- Q: Something that seems to be used in the locomotive brake system. I haven't seen it, either. Who knows? It's better for the locomotive system to go back. Thank you!!

- The pantograph's bow head has several detachable electrically conductive strips of carbon or powder alloy used to contact the contact wire and power it from above.

- Q: How does carbon affect the stability of ecosystems?

- Carbon plays a crucial role in the stability of ecosystems as it is a key component of all living organisms. It affects stability primarily through the carbon cycle, where it is exchanged between the atmosphere, plants, animals, and soil. Carbon dioxide, a greenhouse gas, regulates the Earth's temperature and climate. Excessive carbon emissions from human activities, such as burning fossil fuels, contribute to climate change, which disrupts ecosystems and poses risks to biodiversity, water resources, and food production. Additionally, carbon is essential for photosynthesis, the process by which plants convert CO2 into oxygen and organic compounds, supporting the entire food chain. Hence, its availability and balance are essential for maintaining the stability and functioning of ecosystems.

- Q: How do fossil fuels release carbon into the atmosphere?

- Combustion, a process in which fossil fuels like coal, oil, and natural gas are burned for energy, results in the release of carbon into the atmosphere. This carbon, which had been trapped underground for millions of years, is converted into carbon dioxide (CO2) gas. During combustion, the carbon and hydrogen atoms present in fossil fuels react with oxygen from the air, producing not only CO2 but also water vapor (H2O) and heat. The released CO2 is then emitted into the atmosphere, where it acts as a greenhouse gas. The burning of fossil fuels in various sectors such as transportation, electricity generation, and industrial processes plays a significant role in the escalating levels of atmospheric CO2. The continuous extraction and rapid burning of these fuels have led to a substantial increase in the concentration of CO2 in the Earth's atmosphere over the past century. This rise in atmospheric CO2 is a primary driver of climate change, as CO2 acts as a heat-trapping gas, contributing to the greenhouse effect. The greenhouse effect occurs when the Earth's atmosphere retains the heat radiated from the surface, resulting in a global temperature increase. Therefore, the release of carbon into the atmosphere from fossil fuels is a major concern due to its significant role in climate change and the subsequent environmental and societal impacts. To address these effects, there is a growing global effort to transition towards renewable and cleaner energy sources, reduce fossil fuel consumption, and implement sustainable practices.

- Q: Can barbecue carbon still have the effect of absorbing formaldehyde?

- Yes, there are many things to absorb formaldehyde, but still need to put a little longer, after all, the body is important

- Q: How do plants and trees absorb carbon dioxide?

- Plants and trees absorb carbon dioxide through a process called photosynthesis. Photosynthesis is the process by which plants convert sunlight, water, and carbon dioxide into glucose (sugar) and oxygen. The process takes place in the chloroplasts, which are specialized structures within the plant cells. During photosynthesis, plants absorb carbon dioxide from the atmosphere through tiny pores on their leaves called stomata. The carbon dioxide enters the plant's cells and travels to the chloroplasts. Inside the chloroplasts, energy from sunlight is used to convert the carbon dioxide and water into glucose and oxygen. The glucose produced through photosynthesis is used by the plant as a source of energy for growth, reproduction, and other metabolic activities. Some of the glucose is stored in the plant as starch, while the rest is used to produce other essential compounds. The oxygen produced during photosynthesis is released back into the atmosphere through the stomata. This oxygen is vital for the survival of animals, including humans, as it is necessary for respiration. Overall, plants and trees play a crucial role in absorbing carbon dioxide from the atmosphere through photosynthesis. They act as natural carbon sinks, helping to regulate the levels of this greenhouse gas and mitigate the effects of climate change.

- Q: How do you remove the carbon stains on your clothes?

- Cleaning instructions for clothing * collar / cuff: Soak clothes in warm water with detergent powder for 15-20 minutes before washing. * Yellow White Sox: soaking washing powder for 30 minutes, then normal washing. * milk stains: use washing powder to do stain pretreatment and normal washing. If the milk stains are stubborn, you may need to use a bleach that is harmless to the clothes. * ordinary oil: a strong detergent is used for pre treatment and normal washing; if desired, bleaching of stubborn stains can also be done with bleach. The clothing removal method of rubber and plastic sex pigment stains with rubber and plastic pigment stains, it is difficult to remove, only use a suitable way to remove. 1, adhesive removal of stains clothes with glue stains, can use acetone or banana on glue water stains, use a brush to repeated washing, until soft glue stains off from the fabric, and then rinse with water. Once, can be repeated scrubbing several times, and finally wash. Do not use this method to avoid fabric damage. 2, white latex stain removal of white latex is a kind of synthetic resin, polyvinyl acetate emulsion. It is characterized by the addition of nylon silk and so on, the vast majority of fiber quality materials have bonding role, it can firmly adhere to the clothing. It has another characteristic that can dissolve in a variety of solutions. We will use its own characteristics to find ways to remove. By 60 DEG C or 8:2 alcohol liquor (95%) and a mixture of water, white glue stains on the clothes soak, soak about half an hour later, you can wash with water scrubbing, until...

- Q: How does carbon contribute to the strength of alloys?

- Carbon contributes to the strength of alloys by forming interstitial solid solutions with metals, which increases the hardness and strength of the material. The carbon atoms occupy the spaces between the metal atoms, creating lattice distortions and enhancing the overall strength of the alloy. Additionally, carbon can also form compounds with metals, such as carbides, which further improve the hardness and wear resistance of alloys.

- Q: How does deforestation affect carbon levels?

- Deforestation has a significant impact on carbon levels in the atmosphere. Trees play a crucial role in the carbon cycle by absorbing carbon dioxide (CO2) through photosynthesis and storing it in their trunks, branches, leaves, and roots. When forests are cleared or burned, this stored carbon is released back into the atmosphere as CO2, contributing to the greenhouse effect and climate change. Deforestation not only reduces the number of trees available to absorb CO2 but also disrupts the natural balance of the carbon cycle. Forests act as carbon sinks, meaning they absorb more CO2 than they release, helping to regulate the Earth's climate. When forests are cut down, the carbon stored in their biomass is rapidly released, exacerbating the problem of excess CO2 in the atmosphere. In addition to the immediate release of carbon, deforestation also impacts the long-term carbon storage capacity of the planet. Young trees and newly regrown forests have a lower carbon storage capacity compared to older, mature forests. Therefore, when forests are cleared and replaced with young vegetation or non-forest land uses, the ability to absorb and store carbon is greatly reduced. The consequences of increased carbon levels in the atmosphere are far-reaching. Carbon dioxide is a greenhouse gas that traps heat in the Earth's atmosphere, contributing to global warming and climate change. Rising temperatures have a cascade of effects, including increased frequency and intensity of extreme weather events, rising sea levels, and disruptions to ecosystems and biodiversity. To mitigate the impact of deforestation on carbon levels, it is crucial to prioritize sustainable forest management practices and reforestation efforts. Protecting existing forests and promoting afforestation and reforestation can help restore the carbon-absorbing capacity of the planet and contribute to global efforts in combating climate change.

- Q: The difference between graphite and carbon

- Graphite is a crystalline mineral of carbonaceous elements, and its crystalline framework is hexagonal layered structure

- Q: How dnf advanced carbon ashes?

- Before 70, strengthening with carbon, then the activities in the mall to sell high carbon, have to use coupons to buy, that is to improve the success rate of strengthening, now is also the time to rest, 80 edition, replaced by strengthening the body of the colorless, carbon was automatically replaced colorless (1: 5) senior carbon system did not automatically change on the left

Send your message to us

Calcined Anthracite Coal Carbon Coke for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords