BMT Rolled Prepainted Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

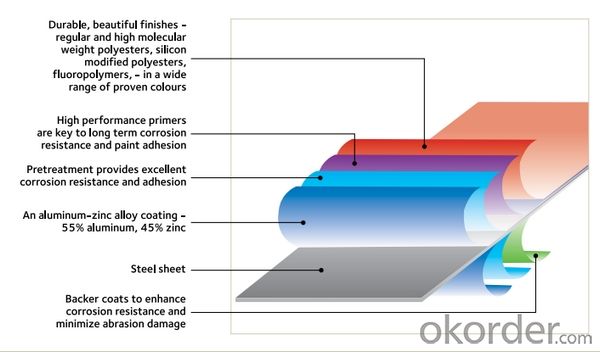

Structure of BMT Rolled Prepainted Steel Coil for Construction

Description of BMT Rolled Prepainted Steel Coil for Construction

BMT Prepainted Rolled Steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Zn coating on both faces by hot dip process. Its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of BMT Rolled Prepainted Steel Coil for Construction

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

3. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of BMT Rolled Prepainted Steel Coil for Construction

1. Construction and building: roofing; ventilating duct; handrail; partition panel

2. Electric appliance: refrigerator; washing machine; refrigerator..

3. Transportation: oil tank; road sign; etc.

4. Agriculture:barn; etc.

5. Others: vending machine; game machine; etc.

Specifications of BMT Rolled Prepainted Steel Coil for Construction

Product | BMT Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.3-3.5mm |

Width | 600-1250mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z35-150g/m2 |

Technique | Raw material: Hot rolled steel coil > Cold rolled>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of BMT Rolled Prepainted Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. What is your MOQ ?

Our MOQ is 50mt. And there is more discount if you order like 1000 tons and more. The more appropriate payment term your can offer, the better price we can provide.

2. What is the general delivery time?

Usually it is within thirty working days after received buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 20- 25 days, but the shipment will depend on the vessel situation.

3. How do you promise the quality of the steels?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. What different between PE and PVDF?

PVDF is the most advanced painting in construction industry, it is with high corrosion resistance and color retention, and the life time could last to 20-25 years. Currently, PE is the most widely-used painting in the color coated steel coils. It is characterized by good overall performance, and high economic as well

- Q: How are steel coils used in the production of electrical connectors?

- Steel coils are used in the production of electrical connectors as they provide a strong and durable core component. The coils are wound into the desired shape and size, and then further processed to create the necessary conductive pathways for electrical current. This ensures stability, strength, and efficient conductivity in the connectors, making them suitable for various electrical applications.

- Q: How are steel coils coated for added protection?

- Steel coils are coated for added protection using a process called coil coating. This process involves the application of a protective layer onto the surface of the steel coil to enhance its durability and resistance to corrosion. There are various methods used to coat steel coils, but the most common one is the continuous coil coating process. In this process, the steel coil is unwound and cleaned thoroughly to remove any contaminants or impurities from the surface. This ensures proper adhesion of the coating material. Once the steel coil is cleaned, it is then pre-treated to enhance its surface properties. This pre-treatment typically involves applying a chemical solution or a conversion coating to the surface of the coil. The purpose of this step is to create a receptive surface for the coating material and enhance its adhesion. After the pre-treatment, the steel coil is coated with a protective layer. This coating material can be a liquid paint, a powder coating, or sometimes a combination of both. The coating is applied uniformly onto the surface of the coil using various techniques, such as roll coating, spray coating, or electrostatic coating. Once the coating is applied, the steel coil is cured or dried using heat or sometimes ultraviolet light. This curing process ensures that the coating material forms a strong bond with the steel surface and achieves the desired protective properties. The coated steel coil is then inspected for quality control measures, such as thickness, adhesion, and appearance. If it meets the required specifications, it is further processed, which may involve cutting, slitting, or forming into the desired shape or size. Overall, the process of coating steel coils for added protection involves thorough cleaning, pre-treatment, application of a protective coating, curing, and quality control. This ensures that the steel coils possess excellent resistance to corrosion, abrasion, and other environmental factors, making them suitable for a wide range of applications in various industries.

- Q: What is the difference between carbon steel and spring steel?? And which is the better one to make swords with??

- Neuropathy Solution can help people of neuropathy to eliminate all the outward indications of this problem including : tingling, prickling feeling , numbness of the area round the affected nerves, quick problems , sharp as well as using feeling in the nerves. Dr. Randall Labrum, the author of this unique guide feels that you will eliminate most of the outward indications of neuropathy and eliminate that dangerous illness permanently.

- Q: How are steel coils inspected for paint adhesion using adhesion testers?

- Steel coils are inspected for paint adhesion using adhesion testers in a systematic and rigorous manner. Adhesion testers are devices specifically designed to evaluate the bond strength between the paint and the underlying steel surface. The inspection process begins by selecting representative samples from the steel coils. These samples are usually cut into smaller sections, ensuring that they are free from any defects or surface irregularities that could affect the adhesion test results. Once the samples are prepared, the adhesion testers are employed to measure the force required to detach the paint coating from the steel surface. The most commonly used adhesion tester is the cross-cut adhesion tester. This device consists of a set of blades arranged in a grid pattern. The blades are used to create a series of cuts through the paint coating down to the steel surface, forming a grid of squares or rectangles. After the cuts are made, a specialized tape is applied to the grid area and pressed firmly onto the surface. The tape is then rapidly pulled off at a 90-degree angle to the surface. The force required to remove the paint coating from the steel is measured and recorded. The results of the adhesion test are evaluated based on predetermined standards or specifications. These standards typically define the minimum acceptable adhesion strength for the specific application or industry. If the measured adhesion strength falls below the specified threshold, it indicates poor paint adhesion, which could lead to issues such as paint delamination or corrosion. In addition to the cross-cut adhesion tester, other adhesion testing methods may also be used, such as the pull-off adhesion tester, where a hydraulic or mechanical device applies a tensile force to a small circular or dolly-shaped test area. The force required to pull off the dolly is measured and used to assess the paint adhesion. Overall, the use of adhesion testers ensures that steel coils are thoroughly inspected for paint adhesion. This helps to identify any potential adhesion issues early on, allowing for appropriate remedial measures to be taken to ensure the longevity and performance of the paint coating.

- Q: How are steel coils used in the production of prefabricated buildings?

- Steel coils are commonly used in the production of prefabricated buildings as they are rolled into sheets and cut into specific lengths to create the structural components such as beams, columns, and frames. These steel components provide strength, stability, and durability to the prefabricated building, making it capable of withstanding various environmental and structural loads.

- Q: How are steel coils used in the production of power generation equipment?

- Steel coils are used in the production of power generation equipment as they are shaped and formed into various components such as turbine casings, generator frames, and steam pipes. These coils provide the necessary strength and durability to withstand the high temperatures, pressure, and mechanical stresses involved in power generation processes. Additionally, steel coils are often coated with protective layers to prevent corrosion, ensuring the longevity and reliability of the equipment.

- Q: Can steel coils be coated with heat-resistant materials?

- Yes, steel coils can be coated with heat-resistant materials.

- Q: How are steel coils used in the manufacturing of conveyor belts?

- Steel coils are used in the manufacturing of conveyor belts as they provide strength, durability, and flexibility to withstand the heavy loads and continuous movement experienced in conveyor systems. The coils are shaped into a continuous loop, forming the core structure of the belt, which is then covered with various materials to enhance grip, prevent slipping, and improve overall performance.

- Q: Are steel coils recyclable?

- Yes, steel coils are recyclable. Steel is one of the most commonly recycled materials in the world. Coils made of steel can be easily melted down and used to produce new steel products, making them a valuable resource for recycling.

- Q: I am searching for an online article which discusses any aspect of the use of austenitic stainless steels. I was just wondering if anyone could help me find one. No sales articles. Thank you!

- *Austenitic, okorder

Send your message to us

BMT Rolled Prepainted Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords