Z140 BMT Rolled Prepainted Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

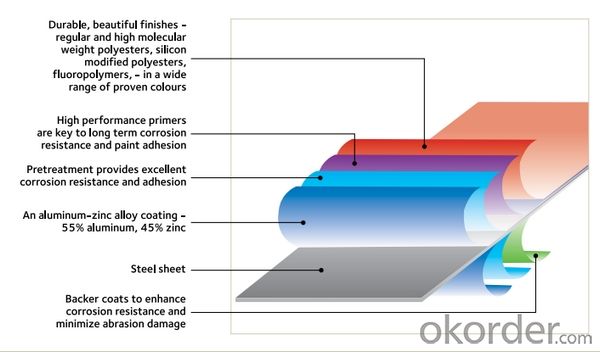

Structure of Z140 BMTZ140 Rolled Prepainted Steel Coil for Construction

Description of Z140 BMT Rolled Prepainted Steel Coil for Construction

BMT Prepainted Rolled Steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Zn coating on both faces by hot dip process. Its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Z140 BMT Rolled Prepainted Steel Coil for Construction

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

3. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Z140 BMT Rolled Prepainted Steel Coil for Construction

1. Construction and building: roofing; ventilating duct; handrail; partition panel

2. Electric appliance: refrigerator; washing machine; refrigerator..

3. Transportation: oil tank; road sign; etc.

4. Agriculture:barn; etc.

5. Others: vending machine; game machine; etc.

Specifications of Z140 BMT Rolled Prepainted Steel Coil for Construction

Product | BMT Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.3-3.5mm |

Width | 900-1250mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z35-150g/m2 |

Technique | Raw material: Hot rolled steel coil > Cold rolled>hot dipped galvanized |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM or 610MM |

Coil weight | 3-7MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z140 BMT Rolled Prepainted Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1: What is your company payment way?

We accept whole T/T or 30% T/T deposit and balance against the copy of B/L. We can negotiate.

2. What is the general delivery time?

Usually it is within thirty working days after received buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 20- 25 days, but the shipment will depend on the vessel situation.

3. How do you promise the quality of the steels?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. What different between PE and PVDF?

PVDF is the most advanced painting in construction industry, it is with high corrosion resistance and color retention, and the life time could last to 20-25 years. Currently, PE is the most widely-used painting in the color coated steel coils. It is characterized by good overall performance, and high economic as well

- Q: What are the different types of steel coil welding methods?

- There are three main types of steel coil welding methods: continuous welding, spot welding, and seam welding. Continuous welding involves joining the edges of steel coils continuously, creating a seamless weld. Spot welding involves applying a series of localized welds at regular intervals along the coil edges. Seam welding is a combination of continuous and spot welding, where a continuous weld is created by intermittent spot welds.

- Q: How are steel coils processed and shaped into specific products?

- Steel coils are processed and shaped into specific products through a series of steps, involving various machinery and techniques. The process begins with the steel coils being unwound and flattened using a decoiler and a leveller. This step ensures that the coils are ready for further processing. Next, the flattened coils are fed into a rolling mill, where they undergo a process called cold rolling. Cold rolling involves passing the coils through a series of rollers to reduce their thickness and improve their surface finish. This process also enhances the strength and hardness of the steel. After cold rolling, the steel coils may undergo additional processes such as annealing or galvanizing, depending on the desired properties of the final product. Annealing involves heating the coils to a specific temperature and then slowly cooling them, which helps to relieve internal stresses and improve the steel's ductility. Galvanizing, on the other hand, involves coating the coils with a layer of zinc to protect them from corrosion. Once the necessary treatments are completed, the steel coils are ready to be shaped into specific products. This is achieved through various methods such as cutting, stamping, or forming. Cutting involves using shears or lasers to trim the coils into specific sizes or lengths. Stamping involves using a die and a press to shape the coils into intricate designs or patterns. Forming, on the other hand, involves bending or shaping the coils using specialized machinery to create curved or contoured products. Finally, the shaped steel products are inspected for quality and undergo any necessary finishing processes such as painting or coating. This ensures that the products meet the required specifications and are ready for distribution or further assembly. In summary, steel coils are processed and shaped into specific products through a combination of steps including unwinding, flattening, cold rolling, annealing or galvanizing, cutting, stamping, forming, inspection, and finishing. Each of these steps plays a crucial role in transforming the raw steel coils into high-quality products used in various industries.

- Q: What are the different types of steel coatings used on coils?

- There are several types of steel coatings used on coils, including galvanized, galvannealed, and organic coatings. Galvanized coatings involve applying a layer of zinc to the steel surface, providing excellent corrosion resistance. Galvannealed coatings involve a two-step process where the steel is first galvanized and then heated to form an alloyed surface layer, offering enhanced paint adhesion and weldability. Organic coatings, on the other hand, use paints or other protective coatings to provide corrosion resistance and aesthetic appeal.

- Q: What are the challenges in coil leveling for coated steel?

- Coil leveling for coated steel presents several challenges due to the additional layer of coating. Firstly, the coating can be sensitive to pressure and friction, making it prone to damage during the leveling process. Maintaining the integrity of the coating while achieving the desired flatness of the steel is a delicate balance. Additionally, the thickness of the coating can vary across the coil, leading to uneven leveling results. The choice of leveling equipment and parameters must be carefully determined to minimize coating damage and ensure consistent flatness throughout the coil. Moreover, the presence of coating can impact the accuracy of leveling measurements, as it may interfere with the sensors or affect the readings. These challenges require careful attention and expertise to successfully level coated steel coils while preserving the quality of the coating.

- Q: I want to anodize steel using heat. some steel turns gray instead of coloring when I heat it up using a torch.

- Steel doesn't anodize in the sense that aluminum and some other metals do. However, it can be heat-colored. The trick is to clean the surface first (it must be oxide free), then heat gently until the colors appear. These are called temper colors in steel. They are due to a thin adherent layer of oxide that forms and thickens as temperature is increased. They are quite temperature dependent. As the steel is heated, the first color to appear is pale yellow. This will progress through darker yellows, browns, purples, and blues as the temperature rises. Above blue, the oxide becomes the gray/black color you are apparently getting - this is the result of heating too fast and too hot. See the chart at the site below for colors in plain carbon steel. Note that the temperatures are pretty low - It all starts around 400 F and if you go above 600 F the show's all over.

- Q: How are steel coils inspected for paint adhesion using adhesion testers?

- Steel coils are inspected for paint adhesion using adhesion testers in a systematic and rigorous manner. Adhesion testers are devices specifically designed to evaluate the bond strength between the paint and the underlying steel surface. The inspection process begins by selecting representative samples from the steel coils. These samples are usually cut into smaller sections, ensuring that they are free from any defects or surface irregularities that could affect the adhesion test results. Once the samples are prepared, the adhesion testers are employed to measure the force required to detach the paint coating from the steel surface. The most commonly used adhesion tester is the cross-cut adhesion tester. This device consists of a set of blades arranged in a grid pattern. The blades are used to create a series of cuts through the paint coating down to the steel surface, forming a grid of squares or rectangles. After the cuts are made, a specialized tape is applied to the grid area and pressed firmly onto the surface. The tape is then rapidly pulled off at a 90-degree angle to the surface. The force required to remove the paint coating from the steel is measured and recorded. The results of the adhesion test are evaluated based on predetermined standards or specifications. These standards typically define the minimum acceptable adhesion strength for the specific application or industry. If the measured adhesion strength falls below the specified threshold, it indicates poor paint adhesion, which could lead to issues such as paint delamination or corrosion. In addition to the cross-cut adhesion tester, other adhesion testing methods may also be used, such as the pull-off adhesion tester, where a hydraulic or mechanical device applies a tensile force to a small circular or dolly-shaped test area. The force required to pull off the dolly is measured and used to assess the paint adhesion. Overall, the use of adhesion testers ensures that steel coils are thoroughly inspected for paint adhesion. This helps to identify any potential adhesion issues early on, allowing for appropriate remedial measures to be taken to ensure the longevity and performance of the paint coating.

- Q: How do steel coils perform in extreme weather conditions?

- Steel coils generally perform well in extreme weather conditions. Steel is a durable and strong material that can withstand high temperatures, extreme cold, and harsh weather elements such as rain, snow, and wind. It has excellent resistance to corrosion, making it suitable for various outdoor applications. However, it is important to note that the performance of steel coils can vary depending on factors such as the specific grade of steel used, protective coatings applied, and the maintenance and care provided.

- Q: What are the common applications of steel coils?

- Steel coils have a wide range of applications across various industries, including automotive, construction, manufacturing, and appliance sectors. They are commonly used in the production of automobiles, machinery, and infrastructure components like bridges and buildings. Additionally, steel coils are utilized in the manufacturing of household appliances, such as refrigerators and washing machines. Their versatility, strength, and durability make steel coils a crucial material for many industrial applications.

- Q: What are the common methods of protecting steel coils from corrosion during storage?

- Common methods of protecting steel coils from corrosion during storage include applying a protective coating or film, using desiccants or moisture-absorbing materials, implementing proper ventilation and climate control, employing corrosion inhibitors or VCI (Vapor Corrosion Inhibitors), and ensuring adequate packaging and sealing to prevent exposure to moisture or contaminants.

- Q: What are the weight ranges for steel coils?

- The weight ranges for steel coils can vary depending on the specific type and thickness of the steel. However, common weight ranges for steel coils typically range from a few hundred pounds to several thousand pounds.

Send your message to us

Z140 BMT Rolled Prepainted Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords