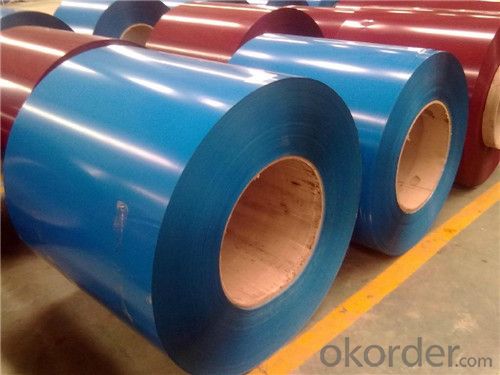

Z19 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z19 BMP Prepainted Rolled Steel Coil for Construction

Description of Z19 BMP Prepainted Rolled Steel Coil for Construction

Metal has the highest value among all cold-rolled steel products. Produced by printing or baking paints onto the surface of cold-rolled steel or GI or ALCOT sheets, pre-coated metal features a wide range of colors and patterns which are commonly used to make the exterior of buildings and consumer electronics products look more polished and sophisticated. Depending on the specific utility of each product, a vast variety of features are available including pollution resistance and anti-bacterial quality

Main Feature of Z19 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Electrical steel sheet

Mainly used to manufacture generating equipment, locomotive, industrial motor and home appliance.

Applications of Z19 BMP PPGI Prepainted Rolled Steel Coil for Construction

Guardrails, ventilation ducts, gutters and down spouts, Pre-paint and post paint applications, gutters and down spouts, ceiling suspension bars, shutter door rails. Auto parts, electrical appliances, refrigerator appliances, signs, automotive parts,vending machines, washing machines, showcases and other structural use, roofing, commercial use

Specifications of Z19 BMP Prepainted Rolled Steel Coil for Construction

Product | Z19 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z19 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: I'm looking for a good source as to the 'structural formula' of steel. I'm not quite sure if that's what it's actually called, but here's a link to what I'm looking for.

- structural formula only apply to a chemical compound, and steel is not that. It is a MIXTURE, an alloy, of iron, carbon, and any of a number of other materials, such as chromium, manganese, etc.

- Q: Want to get stainless steel sink. I want quality, durability, quiet, etc. Any suggestions??

- One part of our home is the kitchen, which is usually one of the busiest parts of the home. And part of it is the kitchen sink; as you look at the sink, you can hardly tell how much work is done in the sink. And in our daily activities, most of us use our sink in our own personal needs. Most of the time, we wash our face and clean our clothes, shoes and anything that needs to be washed in our sink. With this kind of job that the sink is going through in its everyday life, sink must be tough enough to take all the pressure of its job. Ordinary sink will not last long when it is use regularly. It may acquire rust, scratches and dent as we have use it in a regular basis, this is why we need to look for a sink that can manage to handle different usage and tasks in our home. In choosing a sink for our home, we must consider the quality and not the price alone. Stainless steel sink is easy to clean; stain and rust are needed not to worry because stainless steel sink is proven a rustproof material. But of course proper care for the sink should always be taken care of to make use of the sink for a very long time. In shopping for a sink, it can be hassle knowing that stainless steel sink is made of heavy material. And the good news is that stainless steel sink can be bought online. You can shop through the internet and you can have the freedom to choose a sink that will fit your kitchen.

- Q: What is the cost of a steel coil?

- The cost of a steel coil can vary depending on various factors such as the size, thickness, grade, and market conditions. It is best to contact a supplier or check current market prices for an accurate cost.

- Q: What are the challenges in coil blanking?

- In order to achieve efficient and accurate production, coil blanking, a process used to cut flat metal sheets from coiled stock, must tackle several challenges. Some of the key challenges include: 1. Material variations: Coiled stock can have variations in thickness, width, and surface quality, which can impact the cutting process and result in inconsistent blanks. To ensure consistent quality and dimensional accuracy, it is crucial to carefully select and control the material. 2. Coil set and crossbow: Coiled stock often has inherent shape imperfections like coil set (longitudinal curvature) and crossbow (transverse curvature), which can cause alignment issues during cutting. Minimizing these imperfections requires the use of specialized equipment and techniques, such as straighteners and leveling systems. 3. Coil edge condition: The edges of coiled stock can have burrs, waves, or irregularities, which can affect the quality and precision of the cut blanks. Employing proper edge conditioning techniques, like deburring or edge trimming, is necessary to ensure clean and straight edges. 4. Slitting and shearing forces: The forces exerted during coil blanking can induce stresses and strains in the material, potentially leading to deformation or springback. To minimize these effects and maintain dimensional accuracy, careful consideration of slitting and shearing forces, along with proper tooling design and machine settings, is necessary. 5. Scrap and material waste: Coil blanking can generate significant amounts of scrap material, especially during setup and adjustment phases. Managing scrap and reducing material waste is crucial to optimize production efficiency and minimize costs. Efficient nesting algorithms and real-time monitoring systems can help achieve this. 6. Automation and productivity: Due to market demands, coil blanking often requires high-speed and high-volume production. Enhancing productivity can be achieved through the implementation of automation systems, such as robotic material handling and advanced control systems. However, integrating and synchronizing these components with the cutting process requires careful planning and system integration expertise. Overall, addressing these challenges in coil blanking necessitates proper material selection, advanced equipment, specialized techniques, and efficient process control. By overcoming these challenges, manufacturers can achieve consistent quality, dimensional accuracy, and productivity in coil blanking operations.

- Q: How are steel coils used in the manufacturing of steering systems?

- Steel coils are commonly used in the manufacturing of steering systems as they provide the necessary strength and durability required for various components such as steering racks, tie rods, and control arms. The steel coils are typically shaped, formed, and processed to create these parts, ensuring stability, precision, and reliability in steering mechanisms.

- Q: What are the common defects in steel coil surface finishes?

- Common defects in steel coil surface finishes include scratches, pits, roll marks, stains, and unevenness. These defects can be caused by various factors such as improper handling, processing issues, or equipment malfunction. These surface defects affect the aesthetics and quality of the steel coil, making it unsuitable for certain applications or requiring additional processing to rectify the defects.

- Q: This needs to be in a percentage by mass. Could you please also reference where this info has come from. Thanks.

- Graphite is a lot lighter and will allow you to generate more swing speed and probably greater distance. I hit my graphite clubs about one club longer than my steel shafts. But, my steel shafts are far more accurate. I find I hit a lot more greens in regulation using my steel shafted irons than I do with my graphites. Since accuracy is far more important than distance for most people, I choose the steel shafted irons most of the time. You will NEVER see a professional or a low handicapper using graphite irons for this reason.

- Q: How are steel coils used in the production of electrical transmission poles?

- The production of electrical transmission poles relies heavily on steel coils, which are crucial for their strength and durability. These coils, made from high-quality steel, are used to create the poles' main body. They are unrolled and shaped into large cylindrical sections, which are then welded together to form the structure of the pole. This manufacturing process allows for the customization of poles in terms of length, diameter, and wall thickness to meet specific transmission requirements. The utilization of steel coils guarantees that transmission poles possess the necessary structural integrity to withstand demanding conditions such as heavy electrical conductors and environmental factors like wind, ice, and seismic activities. Steel, known for its high strength-to-weight ratio, is an ideal material for these poles as it provides the required strength while keeping the overall weight of the pole relatively low. Furthermore, steel coils also serve in the fabrication of flanges and brackets that attach to the poles. These components are essential for securing and supporting electrical conductors and insulators on the poles. By using steel coils, flanges and brackets can be manufactured with precise dimensions and strength, ensuring a secure and reliable connection between the electrical components and the transmission poles. Apart from their structural advantages, steel coils also offer excellent resistance to corrosion. This characteristic is particularly important for electrical transmission poles, which are exposed to harsh weather conditions and corrosive environments. To enhance the lifespan of the poles, steel coils are typically coated with protective layers such as zinc or epoxy to prevent rust and corrosion. To summarize, steel coils play a vital role in the production of electrical transmission poles. They are used to fabricate the main body of the poles, as well as the flanges and brackets that secure the electrical components. With their high strength, durability, and corrosion resistance, steel coils ensure that transmission poles can safely and reliably support electrical conductors for efficient electricity transmission.

- Q: What are the different methods of joining steel coils?

- There are several methods of joining steel coils, including welding, mechanical fastening, adhesives, and interlocking systems. Welding involves fusing the ends of the coils together using heat or pressure. Mechanical fastening includes using bolts, screws, or other fasteners to hold the coils together. Adhesives can be used to bond the coils, providing a strong and durable connection. Interlocking systems involve designing the coils with special shapes or profiles that fit together, creating a secure joint.

- Q: Steel being my favorite type, I just picked up Heart Gold today, my gf got Soul Silver...I was wondering which steel types are available and somewhat easily obtainable in HG (and/or what is the earliest steel type I can get?)

- for me would be steelex but u have to get onix and get him to level fifty and trade with a friend and he will evolve into steelex as long as your friend gives it back to you lol

Send your message to us

Z19 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords