Blue Aluminum Sheets Sliding Window Interior Window Frame

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Sliding Window Interior Window Frame Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Sliding Window Interior Window Frame :

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

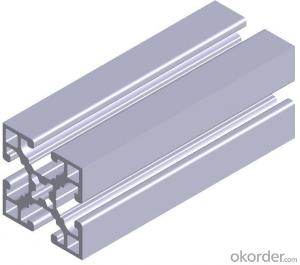

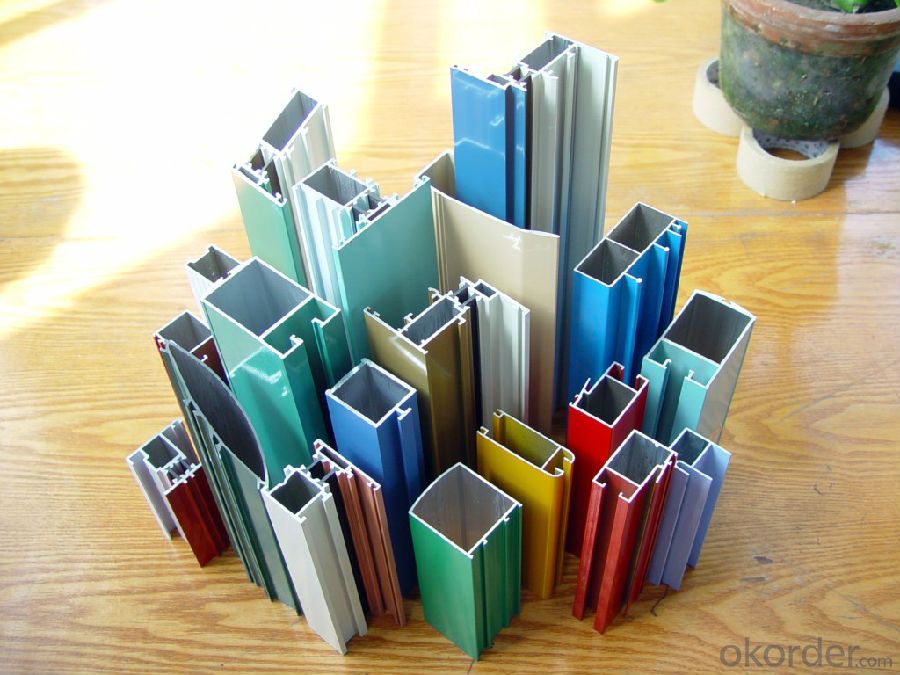

3.Aluminium Sliding Window Interior Window Frame Images:

4.Aluminium Sliding Window Interior Window Frame Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are aluminum sheets fire-resistant?

- Aluminum sheets possess properties that enhance their fire resistance when compared to other materials, although they are not inherently fire-resistant. With a melting point of 1220°F (660°C), aluminum exhibits a resistance to ignition and burning in normal conditions. Moreover, when heated, aluminum does not emit flammable gases and has a low ignition temperature. When subjected to fire, aluminum sheets form a protective oxide layer that functions as a barrier, impeding further combustion and slowing the propagation of flames. This oxide layer also serves as insulation, safeguarding the aluminum from heat and diminishing the risk of structural failure. Nevertheless, it is crucial to acknowledge that despite aluminum sheets surpassing the fire resistance of materials like wood or plastic, intense heat can still cause damage or deformation. Consequently, it is imperative to consider alternative fire safety measures, including the utilization of fire-resistant coatings or the integration of fire suppression systems, to ensure optimal protection against fire hazards.

- Q: Is aluminum sheet resistant to UV rays?

- Yes, aluminum sheet is resistant to UV rays. Aluminum naturally forms a protective oxide layer that acts as a barrier against UV radiation. This oxide layer helps to prevent the aluminum sheet from being damaged or degraded by exposure to the sun's UV rays. This makes aluminum sheet a suitable material for outdoor applications, where it can withstand prolonged exposure to sunlight without fading or deteriorating. Additionally, the reflective properties of aluminum further contribute to its UV resistance, as it can reflect a significant amount of the sun's rays, reducing heat absorption and potential damage.

- Q: Do 101 aluminum sheets have any specific anti-corrosion properties?

- Indeed, specific anti-corrosion properties are possessed by 101 aluminum sheets. When exposed to oxygen, aluminum naturally forms a protective oxide layer on its surface, which acts as a barrier against corrosion. This oxide layer, also referred to as aluminum oxide, exhibits a high resistance to both rust and corrosion. Moreover, the corrosion resistance of 101 aluminum sheets is further enhanced by the addition of small amounts of iron and silicon to the alloy. These sheets are frequently utilized in applications where corrosion resistance is of utmost importance, such as in marine environments, chemical processing plants, and outdoor structures. Nevertheless, it is crucial to acknowledge that although aluminum is highly resistant to corrosion, it can still be susceptible to certain types of corrosion under specific conditions, such as pitting corrosion in chloride-rich environments. Therefore, proper care and maintenance should still be practiced to ensure the durability and effectiveness of 101 aluminum sheets in preventing corrosion.

- Q: Can the aluminum sheets be used for manufacturing chemical reactors?

- Yes, aluminum sheets can be used for manufacturing chemical reactors. Aluminum is known for its excellent corrosion resistance and high thermal conductivity, making it suitable for various industrial applications, including the manufacturing of chemical reactors. Additionally, aluminum is lightweight and easy to shape, allowing for the construction of reactors with different sizes and designs. However, it is important to note that the choice of materials for chemical reactors depends on the specific requirements of the process and the chemicals involved. Certain corrosive or high-temperature environments may require the use of more specialized materials.

- Q: What specific criteria or conditions must be met when utilizing high-quality aluminum sheets in construction?

- <p>High-quality aluminum sheets used in construction projects require adherence to specific standards. They must possess high strength, corrosion resistance, and durability to withstand environmental conditions. Compliance with industry standards such as ASTM or ISO is crucial. Additionally, the sheets should be compatible with other construction materials and meet safety regulations. Proper installation techniques and qualified personnel are also essential to ensure the integrity and longevity of the construction project.</p>

- Q: Are aluminum sheets suitable for soundproofing applications?

- Aluminum sheets are not typically suitable for soundproofing applications as they have low mass and do not effectively block or absorb sound waves.

- Q: Can aluminum sheets be bent?

- Yes, aluminum sheets can be bent as they have malleable properties that allow them to be easily shaped or formed into desired angles or curves.

- Q: What are the safety concerns to be aware of when handling aluminum sheets?

- <p>When working with aluminum sheets, there are a few safety concerns to consider. First, aluminum dust can be a respiratory hazard, so it's important to use proper ventilation and personal protective equipment like masks. Second, sharp edges can cause cuts; always handle aluminum sheets with gloves and proper tools. Additionally, aluminum is a good conductor of electricity, so avoid contact with live electrical wires. Lastly, when cutting or shaping aluminum, eye protection is crucial due to the risk of flying debris. Always follow safety guidelines specific to your workplace and the tools you are using.</p>

- Q: Are 101 aluminum sheets suitable for radiator manufacturing?

- Yes, 101 aluminum sheets are suitable for radiator manufacturing. 101 aluminum is a commercially pure aluminum alloy that offers excellent thermal conductivity, making it ideal for use in radiators. It is also highly corrosion-resistant, which is crucial for radiator applications where exposure to water and other fluids is common. Additionally, 101 aluminum sheets are lightweight and easy to work with, allowing for efficient radiator production processes. Overall, 101 aluminum sheets provide the necessary properties and characteristics required for radiator manufacturing.

- Q: How do aluminum sheets perform in terms of fatigue resistance?

- Aluminum sheets are known for their excellent fatigue resistance. This means they are capable of withstanding repeated cycles of stress and strain without experiencing significant deterioration in their mechanical properties. Fatigue resistance in aluminum sheets is primarily attributed to their microstructure, which consists of small and uniformly distributed grains. This microstructure helps in distributing the applied stress more evenly throughout the material, preventing the formation and propagation of cracks. Additionally, aluminum sheets can be further enhanced for fatigue resistance through various processing techniques such as heat treatment, alloying, and surface treatments. These techniques can refine the microstructure, increase the strength, and improve the overall fatigue performance of the material. Moreover, aluminum has a relatively low density compared to other metals, which contributes to its superior fatigue resistance. The low density allows for better energy absorption during cyclic loading, reducing the likelihood of crack initiation and propagation. However, it is important to note that fatigue resistance can vary depending on the specific alloy, temper, and thickness of the aluminum sheet. Different aluminum alloys have different mechanical properties and fatigue limits, so it is crucial to select the appropriate alloy and temper based on the specific application requirements. Overall, aluminum sheets are well-regarded for their excellent fatigue resistance, making them a popular choice in industries requiring materials that can withstand cyclic loading and extended service life.

Send your message to us

Blue Aluminum Sheets Sliding Window Interior Window Frame

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords