Painted Embossed Internal Color Coating Aluminium Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Embossed Internal Color Coating Aluminium Plate Description:

Color coated aluminium foil combines all advantages of modern coil-coating technology in our full-automatic production line. Our modern production is 4 coated in one with digital precision control, we can created pattern like Wood, stone, graphic as you want. The aluminium substrate gets degreased, chemically pre-treated and coated in a single production step which resulting in a high-quality uniform coatingreproducible at any time and a material which has been developed for easy processing for a variety of application.

2.Main Features of Embossed Internal Color Coating Aluminium Plate:

-High temperature resistant

-Weathering resistant

-Scrubbing resistant

-Sound insulation

-Acid or alkali proof

-Fireproof

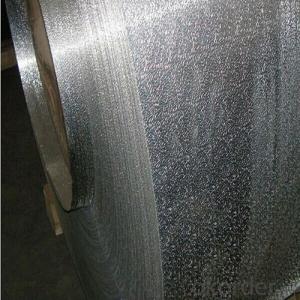

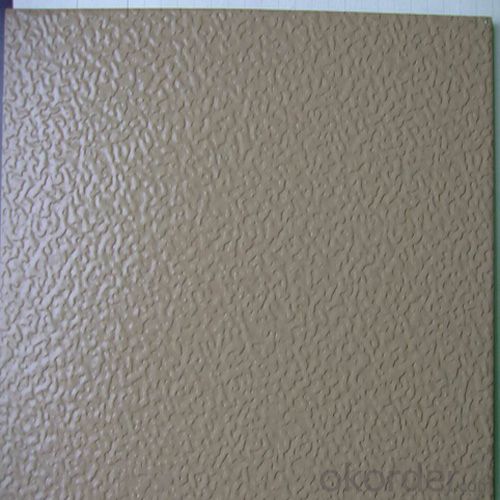

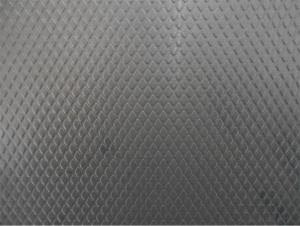

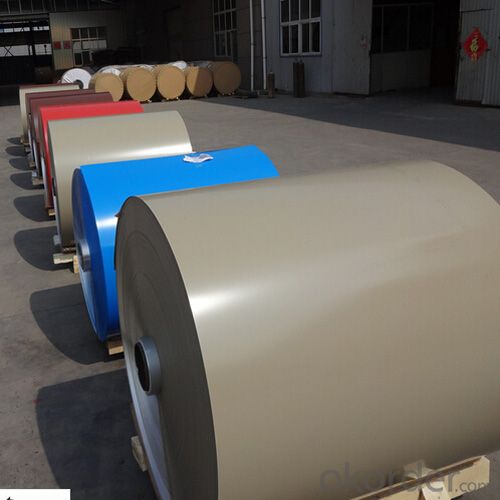

3. Embossed Internal Color Coating Aluminium Plate Images:

4. Embossed Internal Color Coating Aluminium Plate Specification:

| Alloy | AA1100, 3003, 3004, 3105, 5006, 5052, 8011, etc , etc. |

| Temper | H16, H18, H24, H26, H28 |

| Thickness | From 0.1mm to 1.2mm |

| Width | Standard width:1240mm, 1270MM |

| Special width:1000mm, 1200mm, 1240mm, 1270mm, 1520mm, 1620mm | |

| Diameter | Standard dia:1200mm |

| Interior dia: 150mm,405mm, 500mm, 505mm, 510mm | |

| outer diameter: 1200mm | |

| Weight | 2.5 T/coil,3.0 T/coil |

| Coating thickness | PE:>=16 micron , PVDF:>=25 micron |

| Protective film | As per customer's request |

| Coating paint | PVDF, PE(Polyester), epoxy, polyamide, polyurethane |

| Color | Soid, metallic, high gloss,stone,timber,brush,mirror,sparkling, RAL or by customer requirements. |

| Weight | As per customer's request |

| Surface | Embossed, mill finish, coated |

| Gloss | 10-100% |

| Coating Hardness (pencil resistance) | More than 2h |

| Coating adhesion | 1J |

| Impact Resistance | No peeling or cracking(50 kg/cm) |

| Application | ACP,wall cladding,facades,roofs and canopies,ceilings,signboards,blind window,display platforms,electrical panels,etc |

| Coating Thickness | PE coating:more than 16 micron |

| PVDF coating:more than 25micron |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can aluminum sheet be used for aerospace structural components?

- Yes, aluminum sheet can be used for aerospace structural components. Aluminum is a commonly used material in the aerospace industry due to its desirable properties such as high strength-to-weight ratio, corrosion resistance, and good formability. The use of aluminum sheet for structural components allows for the construction of lightweight aircraft, which is crucial for fuel efficiency and performance. Additionally, aluminum is readily available and cost-effective, making it a popular choice for aerospace applications. However, it is important to note that the specific grade and thickness of the aluminum sheet used will depend on the particular requirements and specifications of the aerospace structural component.

- Q: Can 101 aluminum sheets be used in HVAC systems?

- Yes, 101 aluminum sheets can be used in HVAC systems. Aluminum is commonly used in HVAC systems due to its excellent thermal conductivity, corrosion resistance, and lightweight properties. The 101 aluminum alloy is a commonly used grade that provides good strength and ductility, making it suitable for HVAC applications. It is often used for fabricating ducts, air handlers, heat exchangers, and other components in HVAC systems. Additionally, aluminum sheets are easy to work with and can be easily formed and shaped according to the specific requirements of the HVAC system.

- Q: How much is the aluminum plate with a thick 2mm 1000*2000? Thanks

- Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.

- Q: Can 101 aluminum sheets be used in aerospace applications?

- Indeed, aerospace applications can make use of 101 aluminum sheets. This particular alloy, known as 101 aluminum, is widely employed in the aerospace sector because of its remarkable strength-to-weight ratio, superior resistance to corrosion, and impressive formability. It is frequently utilized in the creation of structural elements, including aircraft skins, wings, and fuselage panels. Furthermore, 101 aluminum sheets can be effortlessly machined and welded, rendering them exceptionally suitable for aerospace applications that demand precision and durability.

- Q: Can 101 aluminum sheets be used for roofing or siding?

- Yes, 101 aluminum sheets can be used for roofing or siding.

- Q: How do aluminum sheets perform in terms of electrical insulation?

- Aluminum sheets are not known for their electrical insulation properties. Aluminum is a highly conductive metal, which means it allows electric current to flow through it easily. Therefore, aluminum sheets do not provide effective electrical insulation. If electrical insulation is required, other materials such as plastics or ceramics would be more suitable options.

- Q: Would a chemical reaction happen between a piece of copper and a liquid solution containing a compound of aluminum? Why or why not? FIRST BEST ANSWER GETS POINTS!

- Please don't ask diffuse questions. If you mean a solution of aluminum ions Al+3, then no: Al3+ + 3e? ? Al(s) -1.66 Cu2+ + 2e? ? Cu(s) +0.340 Cu+ + e? ? Cu(s) +0.520 If you mean a solution of some unspecified Al compound then maybe, but there's no way to know until you specify the compound.

- Q: Can the aluminum sheets be used in the construction industry?

- Yes, aluminum sheets can definitely be used in the construction industry. Aluminum is a versatile and lightweight material that offers several advantages for construction applications. It is corrosion-resistant, which makes it ideal for outdoor structures and buildings. Aluminum sheets are commonly used for roofing, siding, window frames, doors, and other architectural elements. Additionally, aluminum's high strength-to-weight ratio allows for the construction of durable and efficient structures. Its malleability also makes it easy to fabricate and shape into various forms, allowing for creative and innovative designs in construction projects. Overall, aluminum sheets are a popular choice in the construction industry due to their durability, versatility, and aesthetic appeal.

- Q: What is the typical fatigue strength of aluminum sheets?

- The typical fatigue strength of aluminum sheets can vary depending on various factors such as the alloy, heat treatment, thickness, surface condition, and the specific application. However, in general, the fatigue strength of aluminum sheets falls within the range of 50-70% of their ultimate tensile strength.

- Q: How is the thickness of aluminum sheets measured?

- The thickness of aluminum sheets is typically measured using a device called a micrometer or caliper. These instruments accurately measure the distance between two opposite sides of the sheet, providing an accurate measurement of its thickness.

Send your message to us

Painted Embossed Internal Color Coating Aluminium Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords