Bleach Water Aluminum Coils with PVDF and PE Color Coating

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 200 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of PVDF Aluminum Coil for ACP Description

PVDF coated aluminum coils are specially processed through the technics of roller coating and baking with precise paints from BECKER INDUSTRIAL COATINGS in Sweden and THE VALSPAR CORPORATION in USA. The main material of PVDF is polyvinylidene fluoride resin; the utmost negative characteristic of the Fl atom can form a very strength high powerful Fl-C bond. Moreover, with the special symmetry molecule structure, the products are of strong weather resistance performance, anti-ultraviolet performance, super long durability and anti-corrosion performance, which can maintain very bright and glossy color even serving for 20 years in outdoor environment. Attributing to the abrasion resistance and impact resistance and flexibility, our products are of excellent mechanical processing performance.

PVDF coated aluminum coils are the highest priority of choice to high class aluminum composite panels, and its composite products are widely used in airport, exhibition center, administration center, star hotel and other symbol building.

2.Main Features of the Aluminum PVDF Coated Coil:

• Light Weight

• High Flatness

• Protecting Environment

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rustproof

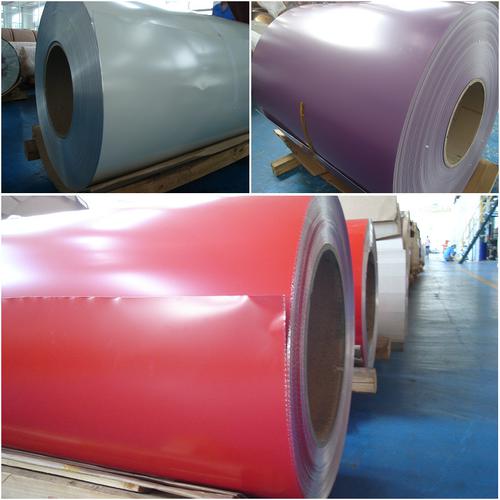

3.Aluminum PVDF Coated Coil Images:

4.Aluminum PVDF Coated Coil Specification:

Aluminum Thickness | Coating Thickness | MEK | T Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥25μm | ≥100 Times | ≤2T | 50kg•cm No falling.No crack | 0 Grade | ≥1H | no change within 2 hours |

0.15-0.28mm | ≥25μm | ≥100 Times | ≤2T | 20kg•cm No falling.No crack | 0 Grade | ≥1H | no change within 2 hours |

PVDF Aluminum Coil for ACP

Features of PVDF Aluminum Coil:

1. Adopting precision rolling coating technology, our PE coated coil can ensure excellent adhesive without coating omission.

2. For the PVDF coated aluminum sheet we produced, there are various colors for your choice.

3. Using infrared heating technology to protect environment from pollution.

4. Our coated aluminum coil has four-roller coating line, uniform coating thickness and good features.

Raw Material of the PVDF Coated Aluminum Coil:

1. Aluminum Coil: high strength aluminum with alloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005 according to customer)

2. Surface Paint: PE, PVDF and special paints.

Specification of the PVDF Coated Aluminum Coil:

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

5.FAQ

1. Color of Card

Our PVDF coated aluminum coil is made of fluorine carbon resin, pigment, ester solvent after high temperature roasting and baking. The paint of this PVDF coated aluminum coils are solidified to dry film with super weather resistance. PVDF coating also can be classified as traditional PVDF and nanometer PVDF coating.

A. Traditional PVDF Coating, with KYNAR500 PVDF and two or three times for coating and baking, has good properties of anti-acid, anti-alkali and is durable in atrocious weather and environment, keeping 15 years no unwonted fading. In view of these facts, we recommend this PVDF coated aluminum coils are applied for external wall cladding.

B. Nanometer PVDF Coating, which different with traditional PVDF, is the clear coating. It contains nanometer element, which can protect panel from pollution, because nanometer has self-cleaning effect, it is easy to get rid of dust and pollution by raining or water.

2. Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal is preferred. If other, it is also acceptable. But the color matching rate may be not good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days, special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible. Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it is suggested all panels are placed in one order for same project. And keep same direction as arrow on protective film when installing to avoid any color difference by vision.

3.How long can we receive the product after purchase?

15-20days for general specification and 35days for special specification after receiving the deposit.

- Q: What is a better deal?Aluminum Cookware ( Paula Deen)orHard Anodized ( Rachael Ray )

- The okorder /

- Q: A nitrate is added with sodium hydroxide, then a piece of aluminum foil. After warming the mixture, ammonia gas is released.A source tells me that aluminum reduces nitrate ion into the ammonium ion. How is this done?

- Aluminum is an active metal and wants to be ionized. Al -- Al(3+) + 3e(-) ?n basic media, tetrahydroxoaluminate complex will be formed: Al(3+) + 4OH(-) -- Al(OH)4(-) ======================================... Al + 4OH(-) -- Al(OH)4(-) + 3e(-) Nitrate is reduced to ammonia in basic media, ammonium in acidic media: N(5+) + 8e(-) -- N(3-) NO3(-) + 8e(-) + 10H(+) -- NH4(+) + 3H2O in basic media, we add base (OH-) to both sides: NO3(-) + 8e(-) + 11OH(-) + 10H(+) -- NH4(+) + 3H2O + 11OH(-) NO3(-) + 8e(-) + OH(-) + 10H2O --- NH3 + 4H2O + 10OH(-) ======================================... NO3(-) + 8e(-)+ 6H2O -- NH3 + 9OH(-) Now, to the balancing of these two redox half reactions: Al + 4OH(-) -- Al(OH)4(-) + 3e(-) NO3(-) + 8e(-)+ 6H2O -- NH3 + 9OH(-) ============================= 8Al + 32OH(-) -- 8Al(OH)4(-) + 24e(-) 3NO3(-) + 24e(-) + 18H2O -- 3NH3 + 27OH(-) ================================== 8Al + 3NO3(-) + 32OH(-) + 18H2O -- 8Al(OH)4(-) + 3NH3 + 27OH(-) //////////////////////////////////////... 8Al + 3NO3(-) + 5OH(-) + 18H2O -- 8Al(OH)4(-) + 3NH3 Hope this helps.

- Q: What are the different sizes available for aluminum coils?

- Aluminum coils are available in various sizes to meet the diverse needs of different industries and applications. The sizes of aluminum coils can vary depending on factors such as the intended use, manufacturing process, and customer requirements. Generally, aluminum coils are available in a range of thicknesses, typically ranging from 0.2mm to 8mm. The width of aluminum coils can vary from as narrow as a few inches to more than 60 inches. The length of aluminum coils can be customized, but standard lengths are often around 1000mm to 6000mm. The specific sizes available for aluminum coils may also depend on the manufacturing capabilities of the supplier or manufacturer. Some suppliers may offer a wide variety of sizes to cater to different customer demands, while others may have a more limited range of sizes. It is important to note that the availability of specific sizes may also be subject to minimum order quantities or lead times. Therefore, it is advisable to consult with the supplier or manufacturer to inquire about the specific sizes available and any limitations or requirements that may apply. Overall, the different sizes available for aluminum coils provide flexibility for customers to choose the most suitable dimensions for their specific applications and requirements.

- Q: This question asks whether aluminum coils can be utilized in various forms and dimensions.

- <p>Yes, aluminum coils can be used in different shapes and sizes. They are versatile and can be cut, shaped, or rolled into various forms to suit specific applications. Aluminum's malleability allows it to be easily manipulated, making it suitable for a wide range of industries, including construction, automotive, and packaging. The size of aluminum coils can also vary, from small coils used for crafts to large ones used in industrial applications. The versatility of aluminum coils makes them a popular choice for many different projects and industries.</p>

- Q: What are the different grades of aluminum used in coils?

- There are several different grades of aluminum used in coils, each with its own specific properties and applications. The most commonly used grades include: 1. 1000 series: This grade of aluminum is commercially pure and has excellent corrosion resistance. It is often used in applications where high corrosion resistance is required, such as in chemical processing equipment or marine components. 2. 3000 series: These alloys are known for their moderate strength and excellent formability. They are often used in cooking utensils, heat exchangers, and general sheet metal fabrication. 3. 5000 series: This grade of aluminum is known for its excellent weldability and corrosion resistance. It is commonly used in marine environments, as well as in transportation and structural components. 4. 6000 series: These alloys are known for their combination of strength, formability, and corrosion resistance. They are widely used in architectural applications, such as window frames, doors, and curtain walls. 5. 7000 series: This grade of aluminum is known for its high strength and toughness. It is often used in aerospace applications, as well as in sporting goods and automotive parts where strength is critical. These are just a few examples of the different grades of aluminum used in coils. The choice of the grade depends on the specific requirements of the application, such as strength, corrosion resistance, formability, and weldability.

- Q: I would like to know because I'm getting a sword with an aluminum sheathe.

- Cinderblock is correct. Alloys can be made of almost anything. Aluminum is made in like 2700 different grades/alloy combinations - some pure, most less so. Aluminum is the 3rd most plentiful element in the earths crust.

- Q: Can aluminum coils be used in automotive applications?

- Yes, aluminum coils can be used in automotive applications. Aluminum is a lightweight and corrosion-resistant material, making it a suitable choice for various automotive components, including coils. Its high thermal conductivity also allows for efficient heat transfer, making it beneficial for applications such as radiators and air conditioning systems.

- Q: What are the potential applications of mill-finished aluminum coils?

- Due to their versatile properties and finishes, mill-finished aluminum coils can be applied in a wide range of industries. Here are some potential uses for mill-finished aluminum coils: 1. In the building and construction industry, mill-finished aluminum coils have numerous applications. They can be employed for roofing, siding, wall cladding, gutters, and downspouts, among other purposes. The mill finish not only enhances the building's aesthetic appeal but also ensures durability and resistance to corrosion. 2. The automotive industry also utilizes mill-finished aluminum coils because of their lightweight nature, high strength-to-weight ratio, and resistance to corrosion. These coils can be used to manufacture body panels, trims, and other components, contributing to fuel efficiency and reducing the overall weight of vehicles. 3. The electrical industry benefits from mill-finished aluminum coils due to their electrical conductivity and corrosion resistance. These coils are employed in the manufacturing of electrical enclosures, transformers, busbars, and conductors. The mill finish guarantees high-quality surface finishes for these electrical components. 4. The packaging industry widely employs mill-finished aluminum coils because of their excellent barrier properties and formability. They are used to manufacture aluminum foil, cans, lids, and other packaging materials. The mill finish provides a smooth surface, making it suitable for printing and branding purposes. 5. Mill-finished aluminum coils are also used in the manufacturing of household appliances like refrigerators, ovens, and air conditioners. These coils offer lightweight and corrosion-resistant solutions for these appliances, ensuring durability and energy efficiency. 6. In the aerospace industry, mill-finished aluminum coils find applications due to their lightweight nature and high strength. They can be utilized to manufacture aircraft structures, interior components, and other parts. The mill finish provides a smooth surface, enhancing aerodynamic efficiency and reducing drag. 7. The marine industry extensively uses mill-finished aluminum coils for various applications. They are employed in the manufacturing of boat hulls, decks, and other components due to their corrosion resistance and lightweight properties. The mill finish ensures a clean and polished appearance, enhancing the vessel's aesthetics. In conclusion, mill-finished aluminum coils possess versatile properties such as lightweight, corrosion resistance, formability, and aesthetic appeal, making them suitable for numerous potential applications across various industries.

- Q: Can aluminum coils be used in the production of cryogenic storage tanks?

- Yes, aluminum coils can be used in the production of cryogenic storage tanks.

- Q: Describe the process of rolling aluminum coil in a few sentences.

- <p>The process of rolling aluminum coil involves several key steps. Initially, aluminum ingots are heated to a specific temperature to make them pliable. Then, they are passed through a series of rolling mills where the ingots are pressed and shaped into thin sheets or coils. This process reduces the thickness and increases the length and width of the material. During rolling, the aluminum may be annealed to improve its ductility and strength. After rolling, the aluminum coil is cooled, cleaned, and inspected for quality. The final step includes coiling the rolled aluminum into manageable rolls for storage and transportation. This process is critical for producing aluminum coils used in various industries such as construction, automotive, and packaging.</p>

Send your message to us

Bleach Water Aluminum Coils with PVDF and PE Color Coating

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 200 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords