Biaxial Geogrids Suppliers Oklahoma USA - Lightweight Fiberglass Polypropylene High Strength Geogrid Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

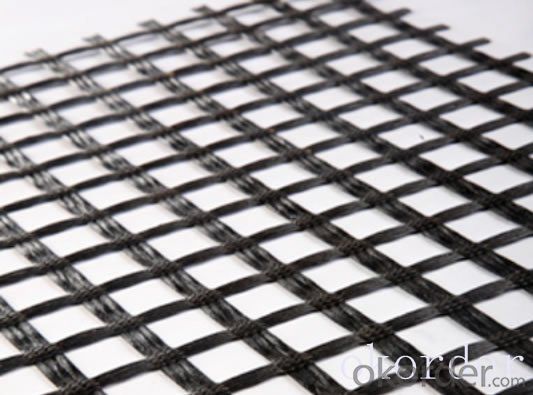

Geogrids form a distinct category of geosynthetics designed for reinforcement. These products are characterized by a relatively high tensile strength and a uniformly distributed array of large apertures (openings between the longitudinal and transverse elements).

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

Model Number:

EGA50-50, EGA80-80, EGA100-100

The outlook of the biaxial geogrid is net work structure like a square. It uses polyester as its raw material and is made of high molecular polymer through extrusion, formed and punched before longitudinally and laterally stretched. This kind of material has a high tensile longitudinally and horizontally, which can be used to reinforce the basement.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geogrids be used in soil stabilization for recreational areas?

- Yes, geogrids can be used in soil stabilization for recreational areas. Geogrids provide reinforcement and stabilization to the soil, preventing erosion and improving load-bearing capacity. This makes them suitable for various recreational applications, such as sports fields, playgrounds, and walking trails, ensuring a safe and durable surface for users.

- Q: What are the factors that affect the design of geogrid-reinforced structures?

- The factors that affect the design of geogrid-reinforced structures include the type and strength of geogrid material, soil properties (such as strength and settlement characteristics), loading conditions, design life requirements, construction techniques, and potential environmental factors (such as temperature variations and chemical exposure). Additionally, factors such as site-specific conditions, project constraints, and regulatory requirements may also influence the design of geogrid-reinforced structures. Overall, a comprehensive understanding of these factors is crucial to ensure the optimal design and performance of geogrid-reinforced structures.

- Q: What does the geotextile 200# mean?

- 200 grams, the unit is g/ square meters per square metre, representing the weight of Geotextiles

- Q: Urgent need!!

- In the local municipal quota to look for, if not, then only by the actual market price in order to supplement the purpose of the form to supplement the input calculation. General municipal quota will have the corresponding sub purpose, you can look at.Fiberglass geogrid with glass fiber rovings as the main raw material, the reticular structure material of the knitting process, to protect and improve the overall use of polyester glass fiber geogrid with high strength aramid fibre filament, warp knitting weaving cloth after directional grid slab, geotechnical grille into coated processing.

- Q: Plastic two-way geogrid hole 4 cm thick, 1 mm wire width of 4 mm

- You say how many grams a square, or how many KN,

- Q: What is the market price of the geotechnical grid in 2017

- (2) 0.3m thick medium (coarse) sand, artificial with mechanical leveling, 25T vibratory roller static pressure two times.

- Q: What is the tensile strength of geogrids?

- The tensile strength of geogrids can vary depending on the specific type and manufacturer, but it is generally high, ranging from several hundred to several thousand pounds per foot.

- Q: What are the benefits of using geogrids in soil reinforcement?

- There are several benefits of using geogrids in soil reinforcement. Firstly, geogrids provide increased stability to the soil, preventing slope failures and soil erosion. They enhance the load-bearing capacity of the soil, allowing for the construction of stronger and more durable structures. Geogrids also improve drainage in the soil by creating a pathway for water to flow through, reducing the risk of water accumulation and soil saturation. Additionally, geogrids can be easily installed and are cost-effective compared to traditional soil reinforcement methods. Overall, the use of geogrids in soil reinforcement improves the overall performance and longevity of the soil and structures built on it.

- Q: Do geogrids affect groundwater flow?

- Yes, geogrids can affect groundwater flow. Geogrids are often used in construction and civil engineering projects to stabilize soil and prevent erosion. They can create a barrier that restricts the movement of water, altering the natural flow of groundwater. However, the extent of this impact depends on the specific design and installation of the geogrids, as well as the local geological conditions.

- Q: What is the meaning of 80 in geogrid TGSG80

- Hello, this is a two-way stretch polypropylene geogrid.

Send your message to us

Biaxial Geogrids Suppliers Oklahoma USA - Lightweight Fiberglass Polypropylene High Strength Geogrid Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords