Cheap Aluminum Sheets for Best Selling Cookware Deep Drawing 1100 Aluminium Circle for Utensils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

1100-H14-DIAMOND EMBOSSED ALUMINUM SHEET

Thickness:1.2mm---4mm,

width:1000mm---1500mm

Product code: 618 a - 33 y titanium matte aluminum plate

Technical parameters

Aluminum alloy/material: 1100

Tensile strength N/was: 115-125

The yield strength of N/was: 150-150

Elongation % : 3 or more

Rainbow degrees: no

Process: light oxidation process

Product description: surface "colored metal silken face" as the main characteristics of the product, completely metal texture, color variety, products can be mild tensile and bending.

Product use: can be used to directly shape stamping, screen printing, thermal transfer two composite process, etc.Used in architectural decoration, household appliances, switch panel, auto parts, lamps lighting, electronic hardware and other industries.

Supply scope of coil or sheet

Mm thickness specification: 0.4 1

Maximum width mm: 1250

The tolerance range

Mm thickness: 0.02 mm

The width of the mm: 2 -

Mm length: 2 -

Actual weight kg: plus or minus 2

Protective film

Protective film on the surface of the aluminum quality assurance period for six months, aluminum is kept dry and ventilated, avoid heat and direct sunlight.If the aluminium material stored in high temperature or direct sunlight can cause protective film, or unable to tear in addition to wait for a phenomenon.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

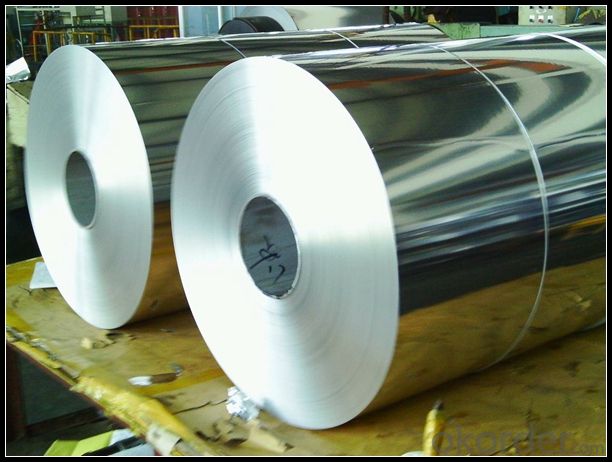

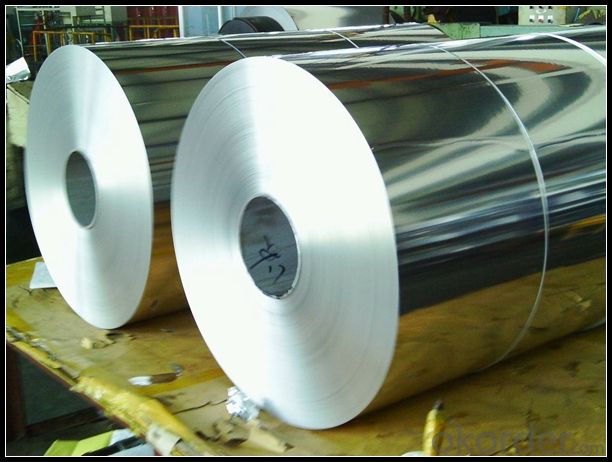

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: How do 101 aluminum sheets compare in terms of strength and durability?

- The mechanical properties and performance characteristics of 101 aluminum sheets are used to evaluate their strength and durability. In terms of strength, these sheets possess moderate strength that is appropriate for various applications. They have a tensile strength of approximately 27,000 psi and a yield strength of around 21,000 psi. This means that they can withstand moderate levels of stress and load without deforming or breaking. Regarding durability, 101 aluminum sheets exhibit good resistance to corrosion, making them suitable for outdoor and marine applications. They also have high resistance to different forms of weathering, including UV radiation and extreme temperatures. Their corrosion resistance is primarily due to the presence of a thin, protective oxide layer on the surface, which prevents further oxidation and ensures long-lasting durability. However, it is important to note that 101 aluminum sheets are not the most durable option available. They are not as strong or durable as certain other aluminum alloys, such as 6061 or 7075, which have higher tensile and yield strengths. Therefore, if a project requires exceptional strength or durability, it may be advantageous to consider using a different aluminum alloy. In conclusion, 101 aluminum sheets offer moderate strength and good durability, making them suitable for a wide range of applications. Nevertheless, if the project necessitates higher strength or exceptional durability, it may be necessary to explore alternative aluminum alloys with superior mechanical properties.

- Q: I recently had a new bridge plate and knobs made from aluminum for my guitar. They are bare uncoated aluminum. How would I go about protecting the parts from oxidation and corrosion? I just worry about the bridge plate because of sweat from playing my guitar near the bridge. There are no local places to get the parts chromed or anodized unfortunately.

- in case you have coverage or can cope with to pay for to - flow see an Ear nostril Throat wellbeing care professional (additionally spoke of as otolaryngologist or ENT for short) it incredibly is the main secure and smartest element to do. maximum probable he will prescribe an ear flush for you that works o.k.. additionally, listening to in triplicate may well be a symptom of nerve inflammtion or different ailment which will properly be examined for quite truthfully by potential of a doctor. Odds are this is not something, yet extra effective risk-free than sorry.

- Q: How do you prevent scratches during transportation of aluminum sheets?

- To prevent scratches during transportation of aluminum sheets, there are several measures that can be taken: 1. Proper packaging: Ensure that the aluminum sheets are packaged securely in appropriate materials such as bubble wrap, foam, or cardboard to provide cushioning and protection from external impacts. 2. Use protective layers: Place protective layers such as paper or plastic film between individual sheets to prevent direct contact and minimize chances of scratching. 3. Secure stacking: When loading aluminum sheets onto transportation vehicles, ensure they are stacked securely to prevent any movement or shifting during transit. This can be achieved by using appropriate strapping or palletizing techniques. 4. Handling with care: Train personnel involved in the transportation process to handle the aluminum sheets with care, avoiding dragging or sliding them against rough surfaces that may cause scratches. 5. Avoid contact with sharp objects: Make sure that the aluminum sheets are not in contact with sharp objects or edges that may cause scratches. This can be achieved by keeping them away from other materials or using protective covers. 6. Regular inspection: Regularly inspect the aluminum sheets during transportation to identify any potential scratches or damages. If any are found, immediate action should be taken to prevent further damage. By following these preventive measures, the chances of scratches occurring during the transportation of aluminum sheets can be significantly reduced, ensuring that the sheets are delivered in optimal condition to their destination.

- Q: Why must the aluminum oxide be electrolyzed in a molten cryolite solution?

- To electrolyse aluminium oxide, it has to be molten. However, the melting point of Al2O3 is extremely high ( 1000°C), and that would make the electrolysis very inefficient. However, Al2O3 dissolves in cryolite at much lower temperatures (lower than 900°C), which makes it a much more viable process.

- Q: why does the bubble apear a few minutes later after putting aluminum sheet into dilute sulphuric acid?

- it firstly etches off the oxide on the surface of aluminum, and then reacts with aluminum, generating bubble.

- Q: Are aluminum sheets suitable for outdoor applications?

- Aluminum sheets are a great choice for outdoor applications. They are durable and resistant to corrosion, which makes them perfect for outdoor environments. They can withstand different weather conditions like rain, snow, and sunlight without getting damaged or losing their strength. Furthermore, aluminum sheets can be coated or painted to make them more resistant to fading, scratching, and other types of wear and tear. This makes them suitable for various outdoor projects like roofing, siding, signage, and decorative elements. Additionally, aluminum is lightweight and easy to shape, making installation and customization a breeze. In summary, aluminum sheets are a dependable and long-lasting option for outdoor projects.

- Q: Can the aluminum sheets be used for manufacturing chemical reactors?

- Yes, aluminum sheets can be used for manufacturing chemical reactors. Aluminum is known for its excellent corrosion resistance and high thermal conductivity, making it suitable for various industrial applications, including the manufacturing of chemical reactors. Additionally, aluminum is lightweight and easy to shape, allowing for the construction of reactors with different sizes and designs. However, it is important to note that the choice of materials for chemical reactors depends on the specific requirements of the process and the chemicals involved. Certain corrosive or high-temperature environments may require the use of more specialized materials.

- Q: Can 101 aluminum sheets be recycled?

- Yes, 101 aluminum sheets can be recycled.

- Q: Can aluminum sheets be anodized without affecting their dimensions?

- Aluminum sheets can undergo anodization without significantly impacting their dimensions. Anodization is an electrochemical procedure that produces a protective oxide layer on the aluminum's surface, enhancing its resistance to corrosion and durability. To perform anodization, the aluminum sheet is immersed in an acidic solution while an electric current is passed through it. This causes the aluminum to oxidize, resulting in the formation of an aluminum oxide layer on the surface. Throughout the anodization process, the aluminum oxide layer grows both inward into the metal and on the surface. The growth of the oxide layer can be precisely controlled by adjusting the duration of the anodization process to achieve the desired thickness. Consequently, the dimensional changes induced by anodization are minimal and can be easily accommodated during the design phase. Nevertheless, it is worth noting that anodization can lead to a slight increase in the thickness of the aluminum sheet. This is due to the growth of the oxide layer on the surface. Typically, the increase in thickness is approximately 50% of the overall thickness of the oxide layer. For instance, if the desired oxide layer thickness is 10 micrometers, the resulting increase in sheet thickness would be approximately 5 micrometers. In conclusion, anodizing aluminum sheets can result in a slight increase in thickness, but the dimensional changes are negligible and can be accurately predicted and taken into account during the design phase. Anodization is a widely used and effective method for enhancing the properties of aluminum sheets without significantly altering their dimensions.

- Q: Do you use aluminum alloy boards or aluminum plates for outdoor billboards?

- Pure aluminum density (P =2.7g/cm3), iron is about 1/3, the low melting point (660 C), aluminum is face centered cubic structure, so it has high plasticity (delta psi:: 32~40%, 70~90%), easy processing, can be made into various sections and plates. The corrosion resistance is good; but pure aluminum strength is very low, the annealed state sigma B is about 8kgf/mm2, it is not as a structural material. Through the long-term production practice and scientific experiments, people gradually to join the alloying elements and the use of heat treatment to strengthen aluminum, which has been a series of Aluminum Alloy. Adding alloy elements to form certain can with high strength in keeping advantages of pure aluminum etc. at the same time, a b value can reach 24 ~ 60kgf/mm2. so that its "strength" (strength and the ratio of the proportion of b/ sigma rho) more than a lot of steel structure become an ideal material, widely used in machinery manufacturing, transport Machinery, power machinery and aviation industry, aircraft fuselage, skin, compressor and so on, often made of aluminum alloy, in order to reduce the weight. Using aluminum alloy instead of steel plate welding, the structure weight can be reduced by more than 50%

Send your message to us

Cheap Aluminum Sheets for Best Selling Cookware Deep Drawing 1100 Aluminium Circle for Utensils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords