Sublimation Aluminum Sheets - Aluminum 1100 1050 3003 Deep Drawing Hot Sale China Cheap Price Aluminum Disc for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

1100-H14-DIAMOND EMBOSSED ALUMINUM SHEET

Thickness:1.2mm---4mm,

width:1000mm---1500mm

Product code: 618 a - 33 y titanium matte aluminum plate

Technical parameters

Aluminum alloy/material: 1100

Tensile strength N/was: 115-125

The yield strength of N/was: 150-150

Elongation % : 3 or more

Rainbow degrees: no

Process: light oxidation process

Product description: surface "colored metal silken face" as the main characteristics of the product, completely metal texture, color variety, products can be mild tensile and bending.

Product use: can be used to directly shape stamping, screen printing, thermal transfer two composite process, etc.Used in architectural decoration, household appliances, switch panel, auto parts, lamps lighting, electronic hardware and other industries.

Supply scope of coil or sheet

Mm thickness specification: 0.4 1

Maximum width mm: 1250

The tolerance range

Mm thickness: 0.02 mm

The width of the mm: 2 -

Mm length: 2 -

Actual weight kg: plus or minus 2

Protective film

Protective film on the surface of the aluminum quality assurance period for six months, aluminum is kept dry and ventilated, avoid heat and direct sunlight.If the aluminium material stored in high temperature or direct sunlight can cause protective film, or unable to tear in addition to wait for a phenomenon.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

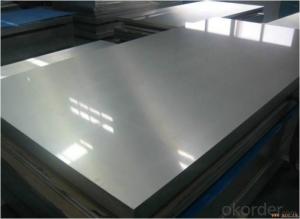

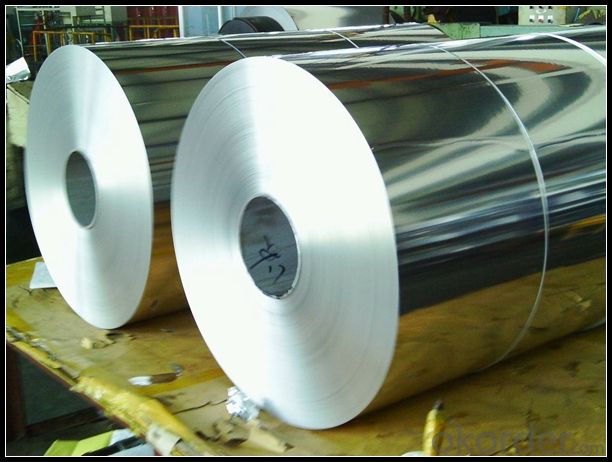

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7 What is Aluminum?

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

- Q: Is it possible to utilize aluminum sheets in the construction of high-rise buildings?

- <p>Yes, aluminum sheets can be used in high-rise buildings. They are valued for their lightweight, high strength, and resistance to corrosion. Aluminum is often used in curtain walls, window frames, and roofing due to its durability and recyclability. It also offers design flexibility and can be easily shaped and joined, making it suitable for modern architectural designs. However, it's important to ensure that the aluminum used meets the specific building codes and safety standards for high-rise construction.</p>

- Q: what's the temperature tolerance of aluminum sheets?

- aluminum is a kind of silver white metal,melting point:660.4℃, boiling point: 2467℃,density: 2.70 g/cm?,very light, about 1/4 of iron's density.it has low hardness and good ductility, which makes it suitable for being pulled into threadlets or pressed into aluminum foils, and the later is usually used for packaging candy and cigarette. it has good electrical and temperature conductivity. it's used for the manufacture of electric wire and cable in electric power industry, and for the manufacture of cooker in daily life bined with the magnesium , copper,zinc,tin,manganese,chromium,zirconium,silicon and other elments,it can formulate various alloys that is broadly used for the manufacture of airplane,car,ship, materials of daily living equipment and the doors and windows of construction industry.aluminum is one of the best reflectors of heat and light, so it is used as thermal insulation material and the manufacture of reflecting mirror in the reflecting telescope.

- Q: This question asks if aluminum sheets can be recycled repeatedly without losing their quality.

- <p>Yes, aluminum sheets can be recycled multiple times without losing their quality. Aluminum is a highly recyclable material, and the recycling process does not degrade the material's properties. In fact, recycled aluminum requires significantly less energy to produce compared to mining and refining new aluminum from bauxite ore. This makes aluminum recycling an environmentally friendly and cost-effective process, contributing to sustainability and reducing the demand for raw materials.</p>

- Q: How do you prevent galvanic corrosion when using aluminum sheets with concrete?

- To prevent galvanic corrosion when using aluminum sheets with concrete, it is essential to use a barrier or protective coating between the aluminum and concrete surfaces. This can be achieved by applying a suitable paint, epoxy coating, or a non-conductive membrane to isolate the aluminum from direct contact with the concrete. Additionally, using corrosion-resistant fasteners made of stainless steel or other compatible materials can further prevent the occurrence of galvanic corrosion. Regular inspections and maintenance are also crucial to identify and address any potential corrosion issues promptly.

- Q: Can the aluminum sheets be used for manufacturing automotive radiators?

- Yes, aluminum sheets can be used for manufacturing automotive radiators. Aluminum is a popular choice for automotive radiators due to its lightweight, excellent heat transfer properties, and corrosion resistance. Aluminum sheets can be easily formed into the required shape and size for radiator construction. Additionally, aluminum radiators offer better cooling efficiency compared to traditional copper radiators. Therefore, using aluminum sheets for manufacturing automotive radiators is a viable and advantageous option.

- Q: This question asks for the current market price of aluminum sheets.

- <p>The price of aluminum sheets in the market can vary significantly based on factors such as grade, thickness, quantity, and market demand. As of my last update, the price per ton of aluminum was fluctuating around $2,000 to $3,000 USD, but this is subject to change. For the most accurate and up-to-date pricing, it's best to check with suppliers or commodity exchanges, as prices can shift daily due to global economic conditions and supply chain dynamics.</p>

- Q: Can aluminum sheets be used for automotive applications?

- Indeed, aluminum sheets find their utility in automotive applications. Being both lightweight and corrosion-resistant, aluminum proves to be an optimal choice for various automotive constituents. Car bodies, engine parts, wheels, and other structural components are commonly constructed using aluminum due to its desirable properties. Aluminum sheets possess an outstanding strength-to-weight ratio, thereby enhancing fuel efficiency and overall vehicle performance. Furthermore, aluminum exhibits commendable thermal conductivity, ensuring efficient heat dissipation in automotive scenarios. Consequently, the utilization of aluminum sheets in automotive production has gained substantial popularity owing to its numerous benefits.

- Q: Are aluminum sheets resistant to impact?

- Aluminum sheets, in general, have a resistance to impact. With its lightweight nature, aluminum is a metal that possesses both strength and toughness, enabling it to endure impact forces. It boasts remarkable energy absorption qualities, facilitating the absorption and dispersion of impact-generated energy, thereby reducing harm to the sheet. Moreover, aluminum sheets can be fortified further through techniques like heat treatment or alloying, enhancing their impact resistance. Nonetheless, the impact resistance of aluminum sheets may fluctuate based on the particular alloy and thickness employed.

- Q: Are the aluminum sheets suitable for manufacturing consumer goods?

- Yes, aluminum sheets are suitable for manufacturing consumer goods. Aluminum is a lightweight, strong, and malleable material that can be easily formed into various shapes and sizes. It has excellent corrosion resistance, which makes it ideal for products that may be exposed to moisture or other harsh conditions. Additionally, aluminum is highly recyclable, making it an environmentally friendly choice. Its aesthetic appeal, durability, and versatility make aluminum sheets an excellent option for manufacturing consumer goods such as kitchen utensils, appliances, furniture, packaging materials, and automotive parts.

- Q: Need to polish some small aluminum tubing, preferably to chrome like shine. What tools do I need? Thinking about buying 6 bench grinder, buffing? wheels and polish compound... Does it sound about right?

- I've done all sorts of tests on this topic and am using a polishing kit that was meant for plastic, but on aluminum, but after all the pads coarse to fine (wet) I found that it's better to use the last pad again but dry, rather than using the while liquid paste they propose. Polishing dry or wet makes a difference, and polishing Al is not the same as polishing a plastic. It's a tricky recipe, you can dull your Al easily, and I never got it shiny like a mirror so I want to see other answrs

Send your message to us

Sublimation Aluminum Sheets - Aluminum 1100 1050 3003 Deep Drawing Hot Sale China Cheap Price Aluminum Disc for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords