Best Quality Cold Rolled Steel Coil JIS G 3302

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 22222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Cold Rolled Steel Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling continuous rolling, degreasing, annealing,skin pass,slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The product is widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

2.Main Features of the Cold Rolled Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

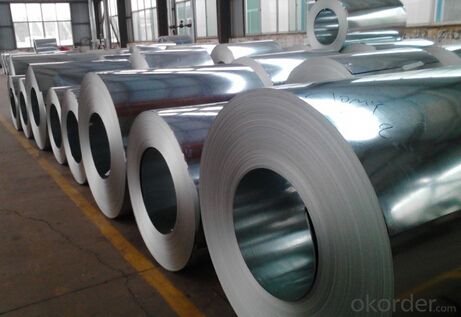

3.Cold Rolled Steel Images

2.Cold Rolled Steel Specification

Standard:AISI,ASTM,DIN,GB,JIS,JIS G3302 ASTM 653M EN10142

Grade: Q195~Q345

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Cold Rolled Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Can steel strips be galvanized?

- Indeed, it is possible to galvanize steel strips. Galvanization involves the application of a protective zinc coating to steel in order to hinder corrosion. This technique is applicable to different types of steel, comprising steel strips. By galvanizing steel strips, their durability and resistance to rust and corrosion are significantly improved, rendering them suitable for a diverse array of applications in industries such as construction, automotive, and manufacturing.

- Q: What is the typical hardness range for steel strips?

- The typical hardness range for steel strips varies depending on the specific type and application, but it generally falls between 20 and 60 on the Rockwell C scale.

- Q: How are steel strips used in the production of surgical instruments?

- Due to their unique properties, steel strips are essential for the manufacturing of surgical instruments. These strips, typically made from high-quality stainless steel, offer exceptional strength, durability, and resistance to corrosion. To begin the manufacturing process, the steel strips are cut into precise dimensions, ensuring uniformity and accuracy in the shape and size of the surgical instrument. Specialized machinery, such as press brakes or bending machines, is then used to shape the strips into various components like handles, blades, clamps, or forceps. To achieve the desired shape and functionality of the surgical instrument, the steel strips undergo additional processing techniques such as forging, stamping, or machining. Forging involves the application of heat and pressure to mold the steel strip into complex shapes, enhancing its strength and durability. Stamping utilizes a die to cut or shape the steel strip, resulting in intricate designs or patterns on the instrument's surface. Machining, on the other hand, utilizes computer-controlled tools to remove excess material and create precise cuts, holes, or threads. Furthermore, heat treatment can be applied to the steel strips to improve the mechanical properties of the instrument, such as hardness or flexibility. This involves subjecting the steel to controlled heating and cooling cycles, resulting in a desired microstructure that enhances the instrument's performance and lifespan. Once the components of the surgical instruments are formed, they undergo meticulous assembly, polishing, and inspection to ensure they meet stringent quality standards. The corrosion-resistant properties of the steel strips are particularly crucial in surgical instruments, as they are exposed to various sterilization methods like autoclaving or chemical disinfection. In summary, steel strips are crucial in the production of surgical instruments, providing strength, durability, and corrosion resistance. Through shaping, processing, and assembly, these strips ensure precision and reliability in surgical procedures.

- Q: How are steel strips typically stored and transported?

- Steel strips are typically stored and transported in a variety of ways to ensure their safety and efficiency. In terms of storage, steel strips are usually stacked in a vertical position. This allows for easy access and organization, as well as minimizing the risk of damage. The strips are often separated by wooden or steel spacers to prevent any contact between them, which could cause scratching or deformation. Additionally, steel strips are typically stored in a covered warehouse or under a protective roof to shield them from the elements and prevent rusting. When it comes to transportation, steel strips are commonly transported by trucks or trains. They are loaded onto flatbed trailers or rail cars, securely fastened to prevent shifting or movement during transit. To protect the strips from damage during transportation, they are often wrapped in plastic or strapped together using metal bands. This ensures that the strips remain intact and undamaged during the journey. In some cases, steel strips may also be transported by ships or airplanes for longer distances or international shipments. When transported by ship, the strips are usually loaded into containers and secured to prevent any movement. Air transportation typically involves packaging the steel strips in specially designed crates or pallets that provide extra protection. Overall, the storage and transportation of steel strips involve careful attention to detail and proper handling techniques to ensure their safety and integrity.

- Q: Can steel strips be used in the production of electrical transformers?

- Yes, steel strips can be used in the production of electrical transformers. Steel is commonly used as a core material in transformer construction due to its high magnetic permeability, which allows for efficient magnetic flux and energy transfer. Steel strips are often used to form the laminated core, ensuring minimal energy losses and improved overall performance of the transformer.

- Q: How do steel strips contribute to weight reduction in products?

- Steel strips contribute to weight reduction in products by providing a strong and lightweight material for various applications. Due to their high strength-to-weight ratio, steel strips allow manufacturers to use less material while still maintaining the required structural integrity. This helps to reduce the overall weight of the product, making it more efficient, economical, and easier to handle.

- Q: How are steel strips used in the manufacturing of storage tanks?

- The manufacturing of storage tanks commonly utilizes steel strips due to their strength, durability, and flexibility. These strips are the primary material for constructing the cylindrical body of the tank. To begin, the steel strips are cut into specific lengths and widths based on the desired size and capacity of the storage tank. They are then shaped into a cylindrical form and joined together through welding to form a seamless structure. This welding process ensures the tank is both leak-proof and capable of withstanding high pressure. The steel strips chosen for storage tank manufacturing are typically made from carbon steel, which offers excellent mechanical properties and resistance to corrosion. This is crucial in order to ensure the tank can withstand harsh conditions such as the storage of corrosive substances or extreme temperature variations. Furthermore, the flexibility of steel strips allows for the customization of storage tanks, giving manufacturers the ability to create tanks of varying sizes and shapes to meet specific storage requirements. Additionally, the steel strips are easy to transport and assemble on-site, making them a favored choice in the manufacturing industry. In conclusion, steel strips play a crucial role in the construction of storage tanks by providing strength, durability, and flexibility. This ensures the safe and efficient storage of various substances.

- Q: How are steel strips processed for precision cutting?

- Steel strips are processed for precision cutting through a series of steps that involve careful planning, material selection, and the use of specialized cutting equipment. The process typically starts with the selection of the appropriate steel grade and thickness based on the specific requirements of the application. Once the steel strips are received, they are inspected for any defects or imperfections that could affect the cutting process. This step ensures that only high-quality materials are used for precision cutting. After inspection, the strips are usually cleaned to remove any contaminants that may have accumulated during storage or transportation. The next step involves the actual cutting of the steel strips. Precision cutting is achieved using advanced cutting equipment such as laser cutters or water jet machines. These machines are capable of producing highly accurate and clean cuts, ensuring that the final product meets the required specifications. During the cutting process, it is essential to maintain proper alignment and positioning of the steel strips. This is typically achieved through the use of clamps, jigs, or fixtures that securely hold the material in place. Precision cutting also requires a high level of control over cutting speed, feed rate, and cutting parameters to achieve the desired results. After the cutting process is complete, the steel strips may undergo additional treatments or finishing processes depending on the specific application. This can include deburring, surface grinding, or heat treatment to improve the overall quality and performance of the final product. In summary, steel strips are processed for precision cutting by carefully selecting the appropriate material, inspecting for defects, and using specialized cutting equipment. The process requires meticulous planning and attention to detail to ensure accurate and clean cuts that meet the required specifications.

- Q: How do steel strips contribute to vibration damping in various applications?

- Steel strips contribute to vibration damping in various applications by absorbing and dissipating vibrational energy. They are commonly used in industries such as automotive, aerospace, and construction. One way steel strips help in vibration damping is through their high density and stiffness. When attached or integrated into a vibrating structure, such as a vehicle chassis or a building frame, the strips act as a mass-spring system. The high density of steel allows it to store a significant amount of kinetic energy, while its stiffness resists deformation under the applied force. This combination helps to reduce the amplitude of vibrations by absorbing and distributing the energy throughout the strip. Moreover, steel strips can be designed with specific shapes, such as corrugations or undulations, to increase their damping capabilities. These shapes create additional frictional forces and increase the internal energy dissipation within the material. As a result, the steel strip absorbs more vibrational energy and reduces the overall level of vibrations. In certain applications, steel strips are also used as part of a tuned mass damper system. These systems are designed to counteract specific resonance frequencies in structures that may cause excessive vibrations. By attaching a steel strip with a specific mass and stiffness, the system can effectively dampen vibrations at the resonant frequency, reducing potential damage and improving overall stability. Furthermore, steel strips can be coated or combined with viscoelastic materials, such as rubber, to enhance their vibration damping properties. The viscoelastic layer acts as a vibration absorber, converting vibrational energy into heat through internal friction. This combination of steel and viscoelastic materials provides a more effective damping solution, particularly in applications where a wider frequency range needs to be addressed. In conclusion, steel strips contribute to vibration damping in various applications by absorbing and dissipating vibrational energy. Their high density, stiffness, specific shapes, and potential combination with viscoelastic materials allow them to effectively reduce vibrations, enhance structural stability, and improve overall performance in industries ranging from automotive to aerospace.

- Q: How are steel strips used in the automotive industry?

- Steel strips are used in the automotive industry for various purposes such as forming body panels, reinforcing structural components, and manufacturing springs and suspension systems.

Send your message to us

Best Quality Cold Rolled Steel Coil JIS G 3302

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 22222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords