Steel Coil In Slip Good Quality Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

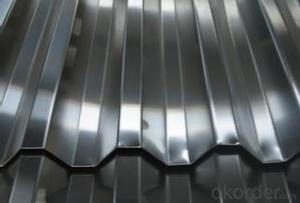

1. Product Description

Narrow strip steel is below 650 mm steel, the product in a bar or roll supplies.Due to the edges of the strip shape after rolling strip steel is more suitable for welding after the slitting, so much for welded pipe, metal construction and daily necessities such as blank.With method of continuous production of narrow strip steel by using many sets of vertical roll mill and obtain good shape of edge, the edge shearing defects such as flash and burr, thus ensuring welding performance.It than with wide strip slitting machine cut into strip saves a vast amount of equipment, so it is more suitable for simple equipment of small and medium-sized enterprises.

2. Main Features

Hot rolled narrow strip in the old open-train mill in the production process of flat steel production process is similar in general section mill;In the new continuous mill production, its technological process and equipment structure form basically similar with wide strip production technology for HSM.Hot rolled narrow strip steel billet for slab and billet used in the production of two.From increasing production capacity and simplify the production process, the slab is good, but must be sufficiently workshop or add big mill to provide.When using billet as blank, although production was lower, but the source is more easily, for small and medium-sized enterprises, have simplified equipment and the advantages of independent production.The main factors influencing the quality of hot rolled narrow strip steel product with billet defects, rolling temperature, rolling tension and roll wear and surface roughness, etc

3. Excellent Product Image

4. Application

The classification of strip steel by the material divided into two categories, ordinary steel strip and high quality steel strip;According to the processing method is divided into hot and cold rolling.The purpose of strip steel is widely used in production of welded steel pipe, cold bending steel billet, manufacturing bicycle frame and wheels

5. FAQ

1.Q: Do you have attended any exhibition?

A: We almost go to Canton Fair and Overseas Exhibitions every year.

2. Q: How to guarantee the quality of the products?

A: We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. Q: How long can we receive the product after purchase?

A: Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

Why choose us?

Pre-sale Service

1. Sample can be offered with sample charge and courier fee by buyer's side.

2. We have full stock,and can deliver within short time.Many styles for your choices.

3. OEM and ODM order are accepted, Any kind of logo printing or design are available.

4. Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you

5. All of our products are produce by our professional workman and we have our high-work-effect foreign trust-worthy sales team.

6. We have 18 years' experience of design, manufacture and sell lingerie, we cherish every order from our honor.

After you choose

1. Count the most efficient shipping cost and make invoice to you at once.

2. Check quality again, then send out to you at 1-2 working day after your payment.

3. Email you the tracking no, and help to chase the parcels until it arrive you.

- Q: What are the different types of slitting techniques for steel strips?

- There are several different types of slitting techniques for steel strips, including rotary slitting, loop slitting, and pull-through slitting. Each technique has its own advantages and is used for specific applications in the steel industry.

- Q: Are steel strips commonly used in the manufacturing of industrial equipment?

- Yes, steel strips are commonly used in the manufacturing of industrial equipment.

- Q: How are steel strips used in the production of electrical contacts?

- Steel strips are used in the production of electrical contacts as they provide the necessary strength and conductivity required for reliable electrical connections. These strips are typically made of high-quality steel alloys that offer excellent electrical conductivity while exhibiting good mechanical properties. The steel strips are first cut into precise dimensions and then undergo various manufacturing processes to shape them into the desired form of electrical contacts. They are often stamped or punched to create the required shape, such as flat or curved contacts. Once the contacts are formed, they are often plated or coated with a thin layer of precious metals like silver or gold. This plating enhances the electrical conductivity of the contacts and also provides corrosion resistance, ensuring long-term reliability of the electrical connections. Steel strips are also used as the base material for bimetallic contacts, which are commonly used in devices where temperature changes can affect the performance of electrical connections. Bimetallic contacts consist of two different metals bonded together, with one metal strip made of steel and another made of a material with a different coefficient of thermal expansion. This combination allows the contacts to expand and contract at different rates, ensuring reliable electrical connections even under varying temperature conditions. In summary, steel strips play a crucial role in the production of electrical contacts by providing the necessary strength, conductivity, and versatility required for various applications. Whether used as standalone contacts or as part of bimetallic structures, steel strips form the backbone of reliable electrical connections in a wide range of devices and systems.

- Q: What are the challenges faced in the production of steel strips?

- There are several challenges faced in the production of steel strips. One of the major challenges is the high energy consumption during the manufacturing process. Steel production requires a considerable amount of energy, both in terms of electricity and fuel. This poses a challenge not only in terms of cost but also in terms of environmental sustainability. Another challenge is the quality control of the steel strips. Ensuring consistent and uniform thickness, width, and surface quality is crucial in producing high-quality steel strips. Any variation in these parameters can lead to defects and inconsistencies in the final product. Maintaining the desired mechanical properties of the steel strips is also a challenge. The production process involves various heat treatments and mechanical processing, which must be carefully controlled to achieve the desired strength, hardness, and ductility of the steel. Any deviation from the required properties can render the steel strips unsuitable for their intended applications. Furthermore, the production of steel strips often involves handling and processing of large and heavy coils. This can be a logistical challenge, requiring specialized equipment and infrastructure for efficient transportation, storage, and handling. Lastly, the steel industry faces the challenge of increasing competition and market demand. To stay competitive, steel manufacturers need to continuously improve their production processes, reduce costs, and meet the changing demands of customers. This requires investment in research and development, as well as adaptation to new technologies and market trends. Overall, the production of steel strips is a complex process that requires overcoming challenges related to energy consumption, quality control, mechanical properties, logistics, and market demands. However, with continuous innovation and improvement, these challenges can be addressed, leading to the production of high-quality steel strips that meet the requirements of various industries.

- Q: How are steel strips used in the production of metal nameplates?

- Steel strips serve multiple purposes in the manufacturing of metal nameplates. Firstly, they act as a strong and durable foundation, guaranteeing the longevity and resistance of the nameplate against damage. Typically, the steel strips are cut into the desired shape and size, forming the basis of the nameplate. In addition, steel strips are commonly employed for the embossing or debossing technique during the nameplate production. This method involves creating raised or recessed designs, logos, or text on the surface of the nameplate. The steel strips are meticulously engraved or stamped with the desired design, and subsequently pressed into the final material of the nameplate, leaving a permanent impression. Furthermore, steel strips can be utilized as a substrate for applying various coatings or finishes to the nameplate. These coatings may consist of protective layers to enhance the nameplate's resistance against corrosion, as well as decorative finishes such as paint, powder coating, or plating. The steel strips provide a smooth and uniform surface for these coatings to adhere to, resulting in a final product that is visually appealing and of high quality. Overall, the use of steel strips is vital in the production of metal nameplates, as they provide a sturdy foundation, facilitate embossing or debossing processes, and allow for the application of coatings or finishes. Their inclusion guarantees the durability, aesthetic appeal, and functionality of metal nameplates in various applications, ranging from branding and labeling to identification and signage.

- Q: What is the role of steel strips in the manufacturing of consumer goods?

- The role of steel strips in the manufacturing of consumer goods is primarily to provide strength, durability, and structural support to the final product. Steel strips are often used in various industries, including automotive, appliances, construction, and packaging, to reinforce and enhance the quality of consumer goods.

- Q: How are steel strips tested for quality assurance?

- Steel strips are tested for quality assurance through various methods such as visual inspection, dimensional measurement, mechanical testing, and chemical analysis. Visual inspection checks for any surface defects or imperfections. Dimensional measurement ensures the strips meet required specifications in terms of thickness, width, and length. Mechanical testing involves assessing the strip's strength, ductility, and toughness through tension, compression, or impact tests. Chemical analysis determines the composition and purity of the steel, ensuring it meets the required standards. These comprehensive testing methods ensure the quality and reliability of steel strips for various applications.

- Q: Are steel strips suitable for the production of metal jewelry?

- Yes, steel strips can be suitable for the production of metal jewelry. Steel is a durable and versatile material that can be shaped, engraved, and polished to create various designs. However, it is important to consider factors like the desired aesthetic, weight, and hypoallergenic properties, as steel may not be ideal for all types of jewelry.

- Q: Can steel strips be used in the renewable energy sector?

- The renewable energy sector can indeed make use of steel strips. These strips possess great versatility and can be applied in various ways within this sector. To illustrate, they find utility in constructing wind turbines, mounting solar panels, and other infrastructure projects connected to generating renewable energy. In the case of wind turbines, steel strips serve as raw materials for manufacturing turbine towers. These towers must be robust and long-lasting to endure the wind's force. Steel strips offer the required strength and stability, rendering them a perfect selection. Moreover, steel strips frequently feature in the creation of solar panel mounting systems. These systems are responsible for securing solar panels in position, guaranteeing optimal sunlight exposure. Given their strength, resistance to corrosion, and economical nature, steel strips are often employed as a structural element. Additionally, steel strips can also be employed in constructing other renewable energy infrastructure, such as hydroelectric and geothermal power plants. These plants necessitate sturdy structures and components, and steel strips can meet the demand for strength and durability. To sum up, steel strips possess a broad range of applications in the renewable energy sector. Their strength, versatility, and cost-effectiveness make them an apt choice for diverse renewable energy projects. Consequently, they contribute to the advancement and expansion of sustainable energy sources.

- Q: Can steel strips be used for making springs in automotive suspension systems?

- Yes, steel strips can be used for making springs in automotive suspension systems. Steel strips are commonly used due to their high strength, durability, and ability to withstand heavy loads and repetitive movements. They provide the necessary flexibility and resilience required for suspension systems to absorb shocks and maintain stability while driving.

Send your message to us

Steel Coil In Slip Good Quality Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords