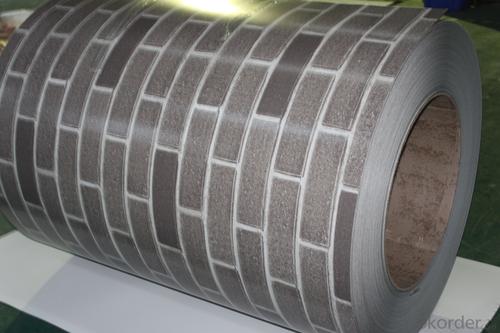

Stone Pattern Printing Steel Plate-1.00mm*1250mm Z60g

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stone Pattern Printing Steel Plate-1.00mm*1250mm Z60g

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

- Q: How are steel strips used in the production of metal doors and windows?

- The production of metal doors and windows relies heavily on steel strips, which serve as a vital component. Typically crafted from high-quality steel, these strips are employed at various stages of the manufacturing process to guarantee the durability, strength, and visual attractiveness of the end product. One of the main applications of steel strips is seen in the construction of door and window frames. These frames provide the essential structural support and stability necessary for the installation and operation of doors and windows. Through cutting, bending, and welding, steel strips are combined to form the desired frame size and shape. The inherent strength and rigidity of steel ensure that the frames can endure the weight of the door or window, as well as external forces. Another critical role played by steel strips is enhancing the security features of metal doors and windows. Often used to reinforce frames and add extra strength, steel strips prevent forced entry. Whether incorporated within the frame structure or applied as reinforcements, steel strips make metal doors and windows more resistant to break-ins, making them an ideal choice for both commercial and residential properties. Moreover, steel strips contribute to the creation of decorative elements on metal doors and windows. They can be shaped, patterned, or designed in various ways to enhance the aesthetic appeal of the product. These decorative steel strips can be customized to match architectural styles or personal preferences, adding a touch of elegance and sophistication to the overall appearance of the doors and windows. To summarize, steel strips are indispensable in the production of metal doors and windows. They are employed in frame fabrication to reinforce structures, ensuring increased strength and security. Additionally, steel strips can serve as decorative elements, providing an appealing finish to the final product. With their versatility and durability, steel strips guarantee that metal doors and windows meet the highest standards in terms of functionality, safety, and aesthetics.

- Q: What are the future trends in steel strip manufacturing?

- Some future trends in steel strip manufacturing include the adoption of advanced automation and robotics technology to enhance production efficiency and reduce costs. Additionally, there is a growing focus on sustainable manufacturing practices, such as using recycled materials and implementing green energy solutions. Industry 4.0 technologies, such as the Internet of Things (IoT) and big data analytics, will also play a significant role in optimizing operations and improving quality control. Furthermore, there is a shift towards developing high-strength steel strips to meet the increasing demand for lightweight materials in sectors like automotive and aerospace.

- Q: How are steel strips stored to prevent contamination?

- Steel strips are typically stored in a controlled environment to prevent contamination. First and foremost, they are stored in a clean and dry area to minimize the risk of moisture and dust accumulation. This is important because moisture can cause corrosion, while dust particles can lead to surface imperfections. To further prevent contamination, steel strips are often wrapped in protective materials such as plastic or paper. These coverings act as a barrier, shielding the strips from direct contact with the surrounding environment. They also ensure that the steel remains free from any potential contaminants that may be present in the storage area. In addition to proper wrapping, steel strips may also be stored on racks or pallets to elevate them off the ground. This helps to prevent contact with any dirt or debris that may be on the floor, reducing the risk of contamination. Regular inspections and maintenance are also crucial in preventing contamination. Storage facilities should perform routine checks to ensure that the environment remains clean and free from any potential contaminants. Any signs of corrosion, moisture, or other contamination should be addressed immediately to prevent further damage to the steel strips. Overall, by implementing proper storage practices, such as maintaining a clean and dry environment, using protective coverings, elevating the strips off the ground, and conducting regular inspections, steel strips can be effectively stored to prevent contamination and maintain their quality.

- Q: How are steel strips processed for improved surface finish?

- Steel strips can be processed in various ways to achieve an improved surface finish. One common method is through the process of pickling and oiling. Pickling involves the immersion of steel strips in an acidic bath, such as hydrochloric acid, to remove any scales or impurities on the surface. This helps to create a clean and smooth surface. After pickling, the strips are rinsed and then coated with oil to prevent oxidation and improve the appearance of the surface. Another method used for improving the surface finish of steel strips is cold rolling. This involves passing the strips through a series of rollers at room temperature, which not only reduces the thickness but also enhances the surface finish. Cold rolling helps to create a more uniform and smooth surface, minimizing any imperfections or roughness. Furthermore, steel strips can undergo annealing to improve the surface finish. Annealing is a heat treatment process that involves heating the steel strips to a specific temperature and then slowly cooling them. This process helps to relieve internal stresses and improve the crystal structure of the steel, resulting in a refined and smoother surface. Additionally, steel strips can be subjected to various mechanical treatments, such as grinding or polishing, to further enhance the surface finish. Grinding involves the use of abrasive wheels or belts to remove any imperfections or roughness on the surface. Polishing, on the other hand, utilizes a fine abrasive material to create a smooth and shiny surface. In summary, steel strips can be processed for improved surface finish through methods such as pickling and oiling, cold rolling, annealing, and mechanical treatments like grinding and polishing. These processes help to remove impurities, reduce roughness, and create a clean and smooth surface, resulting in an enhanced appearance and performance of the steel strips.

- Q: What are the common quality control measures for steel strips?

- To guarantee the highest level of quality and consistency in the production of steel strips, various common quality control measures are employed. These measures encompass: 1. Dimensional checks: Precision instruments are utilized to perform dimensional checks, ensuring that the steel strips meet specific requirements regarding width, thickness, and length, as specified by tolerances. 2. Surface inspection: Visual inspections or automated systems are employed to identify and eliminate surface defects, such as scratches, pits, or rust, ensuring that the steel strips possess a flawless surface. 3. Chemical composition analysis: To fulfill desired strength and durability criteria, the correct chemical composition is crucial for steel strips. Techniques like spectrometry are utilized to verify the steel's composition. 4. Mechanical testing: Tensile strength, yield strength, and elongation are essential mechanical properties for steel strips. Mechanical testing is conducted to verify that the strips meet the specified mechanical requirements. 5. Coating inspection: If the steel strips are coated for protection, it is vital to inspect the coating's adhesion, thickness, and uniformity. Coating inspections are carried out to ensure that the strips are adequately shielded against corrosion. 6. Edge quality assessment: Visual inspections or measuring tools are used to examine the edges of steel strips, ensuring they are smooth, straight, and devoid of burrs or sharp edges. 7. Flatness evaluation: Specialized equipment is employed to measure deviations from a flat plane, ensuring that the steel strips possess a flat and even surface, facilitating proper fit and performance in various applications. 8. Non-destructive testing: Techniques like ultrasonic testing or magnetic particle inspection can be utilized to detect internal defects or irregularities within the steel strips without causing any damage. 9. Packaging and labeling: Quality control measures also encompass appropriate packaging and labeling of steel strips to prevent damage during transportation and ensure easy identification and traceability. By implementing these quality control measures, manufacturers can guarantee that steel strips meet the required specifications and consistently deliver optimal performance across various industries such as automotive, construction, and manufacturing.

- Q: How are steel strips used in the manufacturing of automotive components?

- Due to their versatility and durability, steel strips serve as a crucial element in the production of automotive parts. They are utilized in various ways throughout the manufacturing process. To begin with, steel strips are commonly employed in the creation of body panels and structural components. They are cut and shaped to build the framework and outer shell of the vehicle, providing it with strength and rigidity. The high tensile strength of steel makes it an ideal material for enduring the forces and impacts experienced by automobiles. Furthermore, steel strips are involved in the fabrication of automotive springs, such as suspension and clutch springs. These strips are shaped into the desired form and then subjected to heat treatment to achieve the desired elasticity and resilience. By using steel strips, these critical components can support the weight of the vehicle and offer a smooth and comfortable ride. Moreover, steel strips find their application in the production of automotive fasteners, including nuts, bolts, and clips. These strips are shaped and sized through stamping or machining, ensuring strong and secure connections between various automotive components. The durability of steel guarantees that these fasteners can withstand the vibrations and forces experienced during vehicle operation. Additionally, steel strips are employed in the manufacturing of automotive exhaust systems. They are rolled, bent, and welded to create the necessary pipes and tubing for the exhaust system. Steel's ability to resist high temperatures and corrosion makes it an ideal material for this purpose. In summary, steel strips play a vital role in the manufacturing of automotive components, offering strength, durability, and versatility. Whether utilized in body panels, springs, fasteners, or exhaust systems, steel strips contribute to the overall performance, safety, and longevity of automobiles.

- Q: How do steel strips perform in terms of weldability?

- Steel strips generally have good weldability. The high carbon content and manufacturing process of steel strips ensure they can be easily welded, allowing for strong and reliable joints.

- Q: How are steel strips processed for surface shearing?

- Steel strips are processed for surface shearing by passing them through a shearing machine that cuts off the top layer of the strip, resulting in a smooth and clean surface finish.

- Q: How are steel strips used in the agricultural machinery sector?

- Steel strips are used in the agricultural machinery sector for various purposes such as manufacturing components like blades, cutting edges, and plowshares, providing structural strength to equipment like tractors and harvesters, and reinforcing the framework of machinery to ensure durability and reliability.

- Q: How are steel strips processed for plasma cutting?

- Steel strips are processed for plasma cutting by first cleaning and preparing the surface to remove any contaminants. Then, the steel strip is placed on a cutting table and secured. The plasma cutting machine is programmed with the desired dimensions and shape, and the cutting process begins. The machine uses a high-temperature plasma arc to melt through the steel, creating a precise and clean cut.

Send your message to us

Stone Pattern Printing Steel Plate-1.00mm*1250mm Z60g

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords