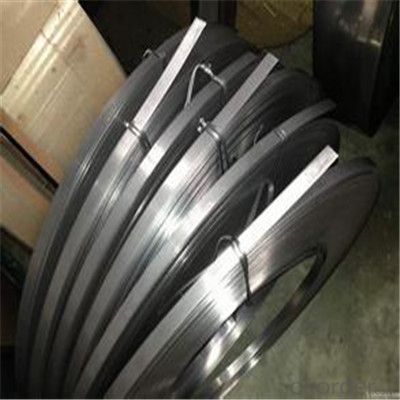

Hot and Cold Rolled Steel Strip Coils Q195 Q235 in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Steel Strip Coils:

Steel strips is one of our main products that is widely used in making band saw blade & other blades to cut paper, weed, etc.

Festures of Steel Strip Coils:

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

4. On/about 1000kgs to be packed with one wooden pallet.

5. Strips can be loaded to 20'FCL without pallet if required by customer.

6. LCL shipment can also be arranged once required by the customer.

Specifications of Steel Strip Coils:

1:Chemical industry equipment, Industrial tanks

2:Medical Instruments,Tableware, Kitchen utensil, kitchen ware

3:Architectural purpose, Milk & Food processing facilities

4:Hospital Equipment, interior Exterior decoration for building

5:Architectural purposes, escalators, kitchen ware, vehicles

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: How do steel strips compare to other materials in terms of strength and durability?

- Steel strips are known for their exceptional strength and durability, making them highly desirable in various applications. When compared to other materials, such as aluminum, plastic, or wood, steel strips generally outperform in terms of both strength and durability. Steel has a high tensile strength, meaning it can withstand large amounts of stretching or pulling forces without breaking or deforming. This makes steel strips ideal for applications requiring structural integrity, such as in construction, automotive, or aerospace industries. In comparison, materials like aluminum or plastic tend to have lower tensile strengths, making them less suitable for heavy-duty applications. Additionally, steel strips exhibit excellent durability, meaning they can withstand wear, impact, and harsh environmental conditions without significant damage or degradation. This durability is especially valuable in industries where materials face constant stress or exposure to extreme temperatures, moisture, or corrosive substances. While other materials may offer some level of durability, steel strips stand out due to their superior resistance against wear and environmental factors. Moreover, steel strips have a long lifespan, which contributes to their overall durability. They are less likely to crack, warp, or decay over time, unlike materials such as wood or plastic. This longevity makes steel strips a cost-effective choice in applications where replacements or repairs would be frequent and costly. In summary, steel strips surpass other materials in terms of strength and durability. Their high tensile strength and exceptional resistance to wear and environmental factors make them the preferred choice for various industries. Whether it is for structural support, heavy-duty applications, or long-lasting durability, steel strips consistently prove their superiority over alternative materials.

- Q: How are steel strips supplied to customers?

- Steel strips are typically supplied to customers in the form of coils or flat sheets, which are produced through a process of hot rolling, cold rolling, or galvanizing. These coils or sheets are then packed and transported to customers through various means such as trucks, ships, or railways, depending on the distance and volume required.

- Q: What are the recycling options for steel strips?

- Steel strips can be recycled through various methods, including collection and sorting at recycling centers, melting down the strips to create new steel products, or repurposing them for other applications. Additionally, steel strips can be sold to scrap metal yards, where they are processed and eventually reused in the manufacturing of new steel products.

- Q: How are steel strips processed for flexibility?

- Steel strips are processed for flexibility through a series of techniques such as cold rolling, annealing, and tempering. Cold rolling reduces the thickness of the steel strip while increasing its length, making it more flexible. Annealing involves heating the strip and then slowly cooling it to enhance its ductility. Tempering further improves flexibility by reheating the steel and then cooling it rapidly. These processes help to manipulate the microstructure of the steel, allowing it to bend and flex without breaking.

- Q: Are steel strips used in the production of solar panels?

- No, steel strips are not typically used in the production of solar panels. The main component of solar panels is silicon, which is a semiconductor material. The silicon is typically processed into thin wafers and then assembled into solar cells, which are then used to create solar panels. Steel strips are more commonly used in construction and manufacturing industries for various purposes such as building structures, automobiles, and appliances.

- Q: What are the different surface etching methods for steel strips?

- There are several different surface etching methods for steel strips, including chemical etching, electrochemical etching, and laser etching. Chemical etching involves immersing the steel strip in a corrosive chemical solution to remove a thin layer of material and create a desired pattern or texture. Electrochemical etching uses an electric current to dissolve the metal surface, resulting in controlled etching. Laser etching utilizes a high-powered laser to selectively remove material from the steel strip, creating precise and detailed markings or patterns.

- Q: Can steel strips be used for making musical instrument strings?

- Musical instrument strings can indeed be fashioned from steel strips. Guitars, pianos, violins, and cellos often employ steel strings. The appeal of steel lies in its resilience, potency, and the vibrant, crisp timbre it delivers, which resonates with numerous musicians. Generally, these steel strips are treated and molded into slender wires that are subsequently coiled or stretched to achieve the intended pitch and sonic excellence. Nevertheless, it is important to acknowledge the individual attributes and needs of each instrument, as specific materials like nylon or gut may be utilized for strings in certain cases.

- Q: How are steel strips used in the production of automotive body reinforcements?

- Steel strips are used in the production of automotive body reinforcements as they provide strength and structural support. These strips are shaped and welded into various components like pillars, beams, and cross members, which help in reinforcing the vehicle's structure and enhancing its overall safety and durability.

- Q: What are the storage guidelines for steel strips?

- To ensure the longevity and prevent damage of steel strips, it is important to adhere to storage guidelines. Firstly, it is crucial to store them in a dry and well-ventilated area to avoid the accumulation of moisture which can lead to corrosion. Direct exposure to sunlight should be avoided as it can cause discoloration and degradation of the steel's surface. Furthermore, steel strips should be stored horizontally, either stacked or on racks, to prevent bending or warping. It is advisable to place wooden or rubber spacers between layers to provide support and prevent contact between the strips which may cause scratching or other surface damage. When stacking the strips, it is necessary to evenly distribute the weight to avoid excessive pressure on the lower strips. Additionally, they should be kept away from chemicals or substances that may stain or react with the steel. Regular inspections should be carried out to identify any rust or damage. If any issues are found, appropriate measures such as cleaning, applying rust inhibitors, or seeking professional assistance should be taken. By following these storage guidelines, steel strips can be preserved in optimal condition, ensuring their quality and performance in various applications.

- Q: What is the meaning of C hot strip material, B material is how to distinguish between

- 1) cold plate used in cold rolling surface nonscale, good quality. The hot surface oxide thickness of hot rolled steel, have difference.2) hot-rolled steel plate toughness and surface roughness is bad, the price is low, and cold rolled plate of good extensibility, toughness, but the price is more expensive.3) rolling is divided into cold-rolled and hot-rolled steel plates, with recrystallization temperature as the regional division.4) cold rolling: cold rolling is generally used to produce strip, and its rolling speed is higher. Hot rolled steel sheet: the temperature of hot rolling is similar to that of forging.

Send your message to us

Hot and Cold Rolled Steel Strip Coils Q195 Q235 in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords