Galvanized Steel Coil/Hot Dip Galvanized Steel Strips Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Steel Coil/Hot Dip Galvanized Steel Strips Coil Specification:

Steel strips coils galvanized

Material: Q195, Q215, Q235, Q345B, SGCC, DX51D+Z

Thickness:0.75-4.5mm

Width:32-750mm

Zinc coating: 60-550g/m2

Galvanized Steel Coil/Hot Dip Galvanized Steel Strips Coil Description:

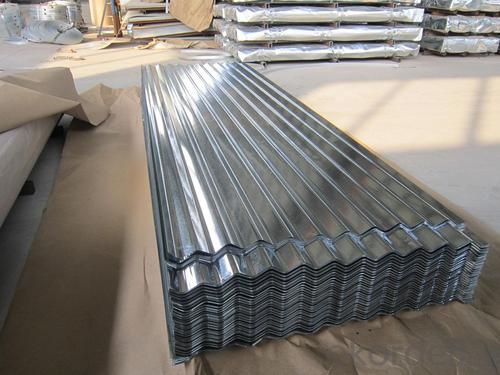

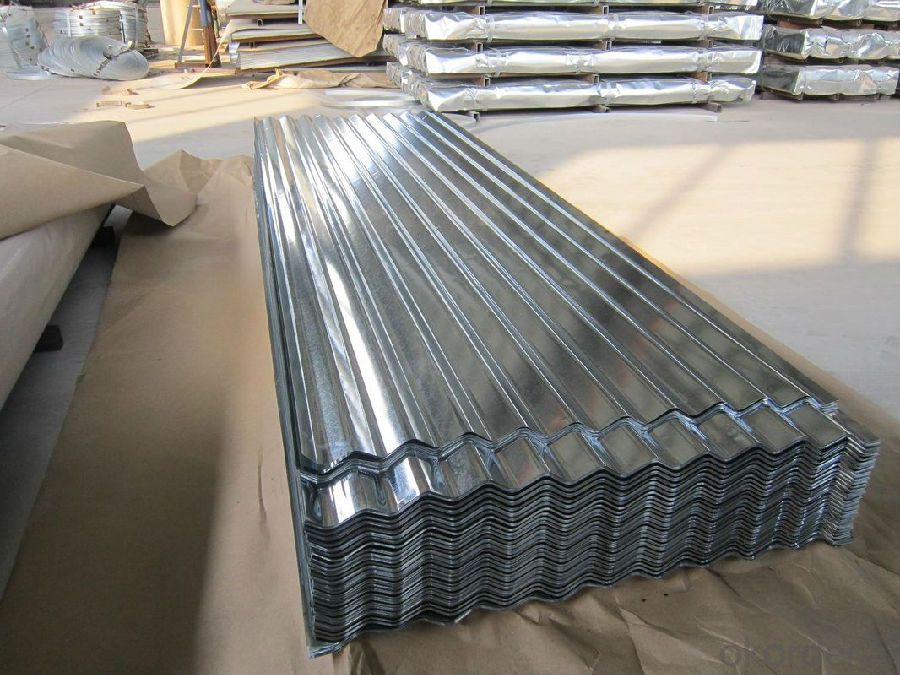

Galvanized steel coil are widely used in the construction industry, as raw material for the production of corrugated panels, fencing products, drywall panel profiles, ventilation systems etc. Recommended for both outside and inside usage, galvanized steel has a high resistance to corrosion in different environments, due to a protective layer of zinc of 100 – 180 grams per square metre.

Main Feature of Galvanized Steel Coil/Hot Dip Galvanized Steel Strips Coil:

Hot-dip galvanized steel coils are produced by immersing steel in a zinc bath. An appropriate galvanizing process requires a pretreatment process during which the steel passes through different baths which prepare the surface for zinc coating. In this stage, chemicals are used to clean the surface of the steel. After the chemical treatment, the steel coils pass through a bath of melted zinc at temperatures around 460 ° C. The resulting uniform coating is finished through a process of skin-passing to provide smooth and shiny appearance of the finished product. To store for a longer period, the hot-dip galvanized coils can be delivered with a final oil coating, according to the customer’s demand.

Galvanized Steel Coil/Hot Dip Galvanized Steel Strips Coil Images: FAQ:

FAQ:

Q: Are you manufacturer of trading company?

A: Yes.

- Q: Can steel strips be coated with protective coatings?

- Yes, steel strips can be coated with protective coatings. Coating steel strips with protective coatings is a common practice in various industries to enhance their durability, resistance to corrosion, and overall performance. There are several types of protective coatings available for steel, including but not limited to, galvanized coatings, powder coatings, epoxy coatings, and paint coatings. Galvanized coatings, for example, involve applying a layer of zinc to the steel strip through a process known as hot-dip galvanizing. This coating provides excellent corrosion resistance and protects the steel from environmental factors such as moisture and chemicals. Powder coatings are another popular option for protecting steel strips. In this process, a dry powder is applied to the steel strip electrostatically, and then it is cured under heat to create a durable and tough coating. Powder coatings offer excellent adhesion and resistance to abrasion, impact, and chemicals. Epoxy coatings, on the other hand, are commonly used to protect steel strips in harsh environments. These coatings are highly resistant to chemicals, moisture, and extreme temperatures. They provide an additional layer of protection to the steel, preventing corrosion and extending its lifespan. Paint coatings are also widely used to protect steel strips. These coatings can be applied by various methods such as spraying, brushing, or dipping. Paint coatings offer flexibility in terms of color options and can provide a decorative finish in addition to protecting the steel strip from corrosion and other damaging factors. In conclusion, steel strips can indeed be coated with various protective coatings to enhance their performance and longevity. The choice of coating will depend on the specific requirements of the steel strip and the environment it will be exposed to.

- Q: Can steel strips be used in the production of surgical implants?

- Yes, steel strips can be used in the production of surgical implants. They are often used as a raw material for manufacturing various types of implants, such as plates, screws, and rods, due to their strength, biocompatibility, and corrosion resistance. Steel strips are commonly utilized in orthopedic, dental, and reconstructive surgeries to provide stability and support in the body.

- Q: What are the different tempering processes for steel strips?

- The different tempering processes for steel strips include annealing, normalizing, quenching and tempering, and stress relieving.

- Q: What are the safety precautions for handling steel strips?

- Some safety precautions for handling steel strips include wearing appropriate personal protective equipment (PPE) such as gloves and safety goggles to protect against cuts and flying debris. It is important to use proper lifting techniques and equipment to prevent strain or injury, and to ensure that the strips are stored and stacked in a stable manner to prevent them from falling or causing accidents. Regular inspection of the strips for any defects or sharp edges is also necessary to minimize the risk of injuries.

- Q: What are the different thicknesses available for steel strips?

- There are various thicknesses available for steel strips, depending on the specific application and requirements. Steel strips can range in thickness from very thin, such as 0.001 inches (0.0254 mm) for ultra-thin strips used in electronics or precision instruments, to much thicker strips used in heavy-duty industrial applications. Common thicknesses for steel strips include 0.020 inches (0.508 mm), 0.030 inches (0.762 mm), 0.040 inches (1.016 mm), 0.050 inches (1.27 mm), 0.060 inches (1.524 mm), and so on. The choice of thickness will depend on factors such as the intended use, strength requirements, durability, and budget. It is important to consult with a steel supplier or manufacturer to determine the most suitable thickness for a specific project.

- Q: Are steel strips commonly used in the manufacturing of electrical appliances?

- Yes, steel strips are commonly used in the manufacturing of electrical appliances. Steel strips are often used as a primary material for the construction of various components in electrical appliances like motors, transformers, and generators due to their high strength, durability, and magnetic properties.

- Q: How do steel strips perform in high-speed applications?

- Steel strips perform well in high-speed applications due to their strong tensile strength and excellent durability. They are capable of withstanding high speeds without bending or warping, ensuring consistent and reliable performance. Additionally, steel strips have good heat dissipation properties, allowing them to dissipate heat effectively during high-speed operations, thereby minimizing the risk of overheating. Overall, steel strips are a preferred choice in high-speed applications for their resilience and ability to maintain stability under demanding conditions.

- Q: Are steel strips suitable for making aerospace components?

- Yes, steel strips can be suitable for making aerospace components depending on the specific requirements and applications. Steel strips offer several advantages such as high strength, durability, and resistance to corrosion, which are important characteristics for aerospace components. They can be used in various applications including structural components, fasteners, and landing gear parts. However, it is important to consider other factors such as weight, fatigue resistance, and temperature limitations when selecting materials for aerospace components. Different types of steel and other materials like aluminum or titanium may be more suitable for certain aerospace applications, so a thorough evaluation of the specific requirements is necessary before determining the suitability of steel strips.

- Q: What are the high speed steel strips and material specifications?

- Cold rolled carbon steel strip is made of high quality carbon structural steel by cold rolling. Because the cold rolled strip can be rolled to a specific heat, the rolling strip is thinner, and has higher dimensional precision and higher strengthCold rolled thin thick hot rolled instead for the same purpose, which can save about 30% steel. According to manufacturing accuracy can be divided into general accuracy (P), width accuracy higher (K), thickness

- Q: How do steel strips compare to other materials in terms of cost and performance?

- Steel strips can be cost-effective and offer excellent performance in various applications compared to other materials. Firstly, steel is a widely available and relatively inexpensive material, making steel strips more affordable than alternatives such as aluminum or titanium. This cost advantage makes steel strips a popular choice in industries where cost-efficiency is crucial. In terms of performance, steel strips offer several advantages. Firstly, steel is known for its high strength and durability, allowing steel strips to withstand heavy loads and resist deformation better than many other materials. This strength makes steel strips suitable for applications that require structural integrity, such as construction and automotive industries. Additionally, steel strips have excellent corrosion resistance properties, especially when coated or galvanized. This resistance to rust and corrosion ensures the longevity of steel strips, reducing maintenance and replacement costs. Moreover, steel strips can withstand extreme temperatures, making them suitable for use in challenging environments. Furthermore, steel strips have good electrical and thermal conductivity, making them ideal for applications that require heat dissipation or electrical grounding. Steel strips are also highly machinable and can be easily formed into various shapes, enabling versatility and flexibility in design. However, it is important to note that the choice of material ultimately depends on the specific requirements of the application. While steel strips offer many advantages, other materials may outperform steel in certain aspects, such as weight or specific chemical properties. Therefore, it is crucial to consider the specific needs and constraints of each project before determining the most suitable material.

Send your message to us

Galvanized Steel Coil/Hot Dip Galvanized Steel Strips Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords