Berger Aluminum Coil - Aluminium Profiles for Window, Door, and Heat Sink Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Profiles Window and Door Profiles Heat Sink Profile Description:

Aluminium Profiles Window and Door Profiles Heat Sink Profile(also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profiles Window and Door Profiles Heat Sink Profile:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

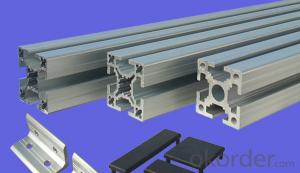

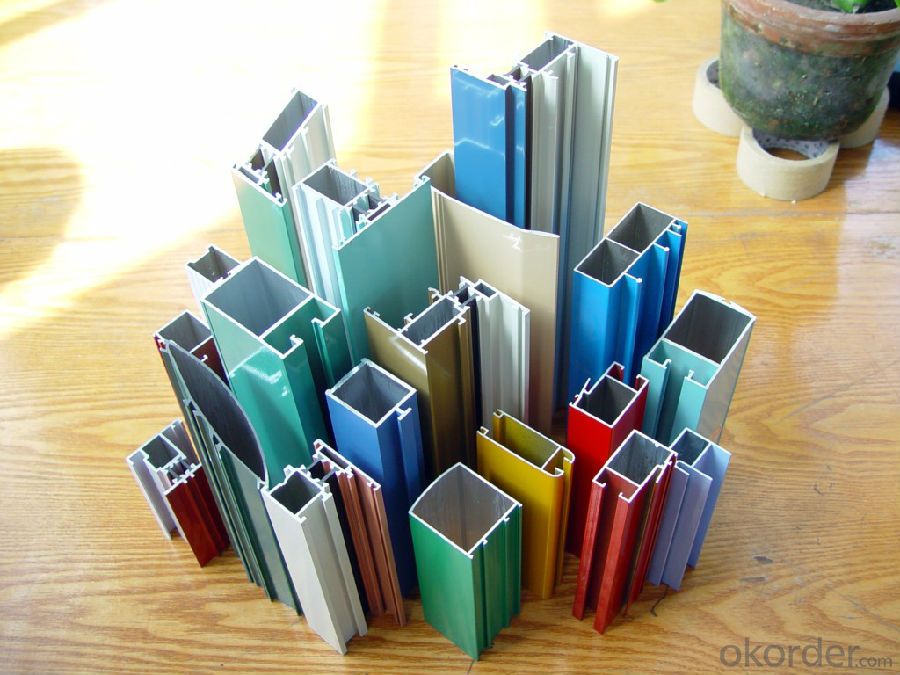

3.Aluminium Profiles Window and Door Profiles Heat Sink Profile Images:

4.Aluminium Profiles Window and Door Profiles Heat Sink Profile Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the shear strength of aluminum coils?

- Various factors, such as alloy composition, temper, thickness, and processing conditions, can cause the shear strength of aluminum coils to vary. When compared to materials like steel or titanium, aluminum alloys generally have lower shear strength. However, the primary considerations for using aluminum coils are their lightweight nature, corrosion resistance, and malleability, rather than their shear strength. To obtain a more precise answer, it is necessary to specify the exact alloy, temper, and dimensions of the aluminum coil in question. These factors greatly impact the shear strength of the material. Additionally, it is important to note that factors like impurities, heat treatment, and the manufacturing process employed can influence shear strength. In conclusion, the shear strength of aluminum coils can differ based on various factors, and it is crucial to consider the specific alloy, temper, and dimensions to determine the exact strength of the material for a given application.

- Q: I have a school project due in a couple weeks and I need to make a life size sculpture of a camera. I don't want to make it solid because that would use a lot of clay and wouldn't evenly cook. Can I put something inside like aluminum foil?

- What kind of clay and what kind of cooking?

- Q: What are the advantages of using aluminum coils in HVAC systems?

- There are several advantages of using aluminum coils in HVAC systems. Firstly, aluminum coils are significantly lighter compared to traditional copper coils. This makes them easier to handle and install, reducing the overall labor and transportation costs. Additionally, the lighter weight of aluminum coils puts less stress on the HVAC system, resulting in less wear and tear over time. Another advantage of aluminum coils is their superior resistance to corrosion. Aluminum is naturally resistant to rust and oxidation, which can prolong the lifespan of the coils and enhance the overall durability of the HVAC system. This resistance to corrosion also helps maintain the efficiency of the system, as the coils remain clean and free from clogs caused by debris buildup. Moreover, aluminum coils have excellent heat transfer properties. They can efficiently absorb and release heat, allowing the HVAC system to cool or heat the air more effectively. This improved heat transfer efficiency can result in energy savings and reduced operating costs, as the system requires less energy to achieve the desired temperature. Furthermore, aluminum coils are more environmentally friendly compared to copper coils. Aluminum is a highly recyclable material, and using aluminum coils can contribute to reducing waste and conserving resources. Additionally, the process of manufacturing aluminum coils requires less energy and produces fewer greenhouse gas emissions, making it a more sustainable choice for HVAC systems. In summary, the advantages of using aluminum coils in HVAC systems include lighter weight, corrosion resistance, superior heat transfer properties, energy efficiency, and environmental sustainability. These benefits make aluminum coils a preferred choice for many HVAC professionals and homeowners alike.

- Q: Consider the following ionization energies for aluminum:Al(g) → Al+(g) + eI1 = 580 kJ/molAl+(g) → Al2+(g) + eI2 = 1815 kJ/molAl2+(g) → Al3+(g) + eI3 = 2740 kJ/molAl3+(g) → Al4+(g) + eI4 = 11,600 kJ/mol A) Account for the trend in the values of the ionization energies.B) Explain the large increase between I3 and I4.

- aluminum forms an ion by loosing electrons. once an electron is lost, the nucleus attains net positive charge. as a result, the remaining electrons are strongly held by nuclea force of attraction, hence more energy is required to remove them.

- Q: Is it possible to utilize aluminum coils in creating art pieces or decorative items?

- <p>Yes, aluminum coils can be used to make artworks or decorations. Aluminum's malleability and durability make it an excellent material for crafting. It can be bent, twisted, and shaped into various forms, allowing for creative expression in art and design. Additionally, aluminum's resistance to corrosion and weathering makes it suitable for both indoor and outdoor decorative pieces. Artists often appreciate its lightweight nature and the metallic finish that can be polished or painted, offering versatility in artistic applications.</p>

- Q: How are aluminum coils measured and specified?

- Aluminum coils are typically measured and specified using two key parameters: thickness and width. The thickness of an aluminum coil refers to the thickness of the aluminum sheet used to make the coil, and it is commonly measured in millimeters (mm) or gauge. The width of a coil, on the other hand, refers to the width of the aluminum sheet that is wound into a coil shape and is usually measured in inches or millimeters. These measurements and specifications are crucial in determining the suitability of the coil for various applications and manufacturing processes.

- Q: How are aluminum coils packaged for transportation?

- Aluminum coils are typically packaged for transportation in a way that ensures their safety and prevents damage. The packaging process involves several steps to ensure that the coils are well-protected during handling, storage, and shipping. Firstly, the aluminum coils are usually wrapped in a protective material such as plastic or paper to safeguard them from dust, moisture, and other external factors. This wrapping helps to maintain the quality and integrity of the coils throughout the transportation process. After wrapping, the coils are then placed onto a pallet or wooden skid. This allows for easy handling with forklifts or other machinery during loading and unloading. The coils are securely strapped to the pallet to prevent any movement or shifting during transportation, minimizing the risk of damage. To provide additional protection, the coils may be placed inside a wooden or metal crate. This crate acts as a further barrier against potential impacts or rough handling that may occur during transit. The crates are carefully designed to fit the size and shape of the aluminum coils, ensuring a snug fit and preventing any unnecessary movement. Furthermore, depending on the specific requirements and distance of transportation, the coils may also be packed inside a shipping container. This offers an additional layer of protection against external elements and provides stability during long-distance transportation. Overall, the packaging process for aluminum coils prioritizes their safety and protection during transportation. The use of protective wrapping, pallets, crates, and shipping containers ensures that the coils arrive at their destination in optimal condition, ready for further processing or usage.

- Q: Can aluminum coils be used for roofing?

- Yes, aluminum coils can be used for roofing. Aluminum is a popular and commonly used material for roofing due to its durability, lightweight nature, and resistance to corrosion. It is often chosen for its ability to withstand harsh weather conditions and its long lifespan, making it a suitable option for various roofing applications.

- Q: How are aluminum coils used in packaging?

- Aluminum coils are widely used in packaging due to their excellent properties and versatility. These coils are usually made from aluminum alloy, known for its lightweight yet strong characteristics. One common application of aluminum coils in packaging is in the production of aluminum cans. The coils are rolled into thin sheets, which are then formed into cans of various shapes and sizes. The lightweight nature of aluminum makes it ideal for manufacturing cans that are easy to transport and handle, reducing overall packaging weight. Aluminum coils are also used in the production of flexible packaging materials such as foils and laminates. These materials are commonly used for packaging food products, pharmaceuticals, and other perishable goods. The flexibility of aluminum allows it to be easily shaped and formed into different packaging formats, ensuring efficient and convenient use. Another important use of aluminum coils in packaging is in the production of closures and bottle caps. Aluminum closures provide an airtight seal, protecting the contents of the package from external factors such as moisture, contaminants, or oxidation. Additionally, aluminum closures can be easily opened and closed, providing convenience to consumers. Furthermore, aluminum coils are employed in the production of blister packs, which are widely used in the pharmaceutical industry. Blister packs consist of a plastic sheet with aluminum foil lamination, creating a barrier against moisture, light, and oxygen. This packaging format ensures the integrity and safety of pharmaceutical products by protecting them from degradation or contamination. In summary, aluminum coils are extensively used in packaging due to their lightweight, strength, and versatility. These coils are transformed into various packaging formats such as cans, flexible foils, closures, and blister packs, providing durability, protection, and convenience to both manufacturers and consumers.

- Q: i am thnking of building my own aluminum john boat and using the propulsion from a jetski to power it, i was wondering if anyone had taken on a project like this and had a few pieces of advice to offer while i am still in the planning stages. the biggest concern i have right now involves the tunnel for the intake, should i use the original fiberglass from the jetski or build up a tunnel out of aluminum for it?

- 518 okorder /

Send your message to us

Berger Aluminum Coil - Aluminium Profiles for Window, Door, and Heat Sink Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords